Leading Light Indigo Color Company - Quality Pigments & Dyes

Industry Trends and the Evolving Landscape of Indigo Dyes

The global textile and chemical industries are undergoing significant transformations, driven by demands for sustainability, efficiency, and superior product performance. Within this dynamic environment, the market for indigo dyes, particularly high-purity and eco-friendly variants, is experiencing a renaissance. Modern manufacturing processes are focused on reducing environmental impact, optimizing resource utilization, and ensuring the highest levels of dye fastness and application consistency. This shift directly impacts how a leading light indigo color company navigates production, supply chain management, and client engagement, emphasizing innovation and adherence to stringent international standards.

Emerging trends include a heightened focus on closed-loop systems, enzymatic reduction technologies for indigo, and the development of greener chemical auxiliaries that work synergistically with the dye. Consumers and regulatory bodies alike are pushing for textiles that are not only aesthetically pleasing but also produced responsibly, from raw material sourcing to final product finishing. This translates into a strong market preference for manufacturers that can demonstrate robust environmental stewardship and provide comprehensive technical data supporting the sustainability claims of their products. The demand for consistent quality from light indigo color exporters is also paramount, as global supply chains require reliability and adherence to strict specifications across diverse markets.

Introducing Indigo Blue Vat Blue: A Premium Solution

Our flagship product, Indigo Blue Vat Blue, represents the pinnacle of modern dye technology, engineered to meet the rigorous demands of the textile and industrial sectors. As a highly purified form of indigo dye, it offers unparalleled depth of color, exceptional fastness properties, and superior application performance. This product is a testament to our commitment to delivering only the highest quality solutions to our global clientele. It addresses the critical need for a stable, vibrant, and reliable blue colorant that performs consistently across various dyeing methods, from traditional denim production to advanced textile finishing.

The chemical integrity of Indigo Blue Vat Blue ensures its stability during storage and processing, minimizing degradation and maximizing color yield. Its fine particle size and excellent dispersion characteristics contribute to uniform dyeing, reducing spotting and uneven coloration that can plague lesser quality dyes. This precision in formulation underscores why discerning buyers consistently choose our offerings, positioning us as a preferred light indigo color product provider globally. Our dedication to research and development ensures that Indigo Blue Vat Blue remains at the forefront of dye technology, continuously optimized for performance and environmental compliance.

Advanced Manufacturing Process Flow for Indigo Blue Vat Blue

The production of Indigo Blue Vat Blue by our light indigo color company follows a meticulously controlled, multi-stage process designed to ensure exceptional purity and consistent quality. This sophisticated manufacturing sequence integrates state-of-the-art chemical synthesis with advanced purification techniques, reflecting our expertise as one of the leading light indigo color factories.

- Raw Material Sourcing & Preparation: High-grade aniline, formaldehyde, sodium amide, and other critical precursors are sourced from certified suppliers. Each batch undergoes stringent quality checks to confirm purity and compliance with internal and international standards. This initial phase is crucial for the integrity of the final product.

- Isatin Synthesis: The process begins with the reaction of aniline with formaldehyde and hydrogen cyanide to form N-phenylglycine. This intermediate is then cyclized to form indoxyl, which is immediately oxidized to isatin. This step, involving complex organic reactions, is optimized for yield and purity.

- Indigo Formation (Vatting): Isatin is then condensed with a reducing agent (e.g., sodium dithionite in an alkaline solution) under carefully controlled conditions to form the leuco-indigo. This soluble form is crucial for effective dyeing. Precision control of temperature, pH, and reactant ratios prevents undesired side reactions and ensures the formation of the correct chromophore.

- Oxidation and Precipitation: The leuco-indigo solution is then exposed to air (oxygen), which oxidizes it back to insoluble indigo pigment, precipitating out of the solution. This crystalline formation process is meticulously managed to control particle size and morphology, which are critical for tinting strength and dispersion.

- Purification and Filtration: The crude indigo is then subjected to a series of washing and filtration steps to remove impurities, unreacted starting materials, and by-products. Our facilities utilize advanced filtration technologies, including membrane filtration and centrifugation, to achieve exceptionally high purity levels.

- Standardization and Drying: The purified indigo paste is then standardized to precise color strength and moisture content. It is then carefully dried using methods such as spray drying or vacuum drying, which preserve the crystal structure and ensure the final powder or granule form is stable and easy to handle.

- Quality Control & Packaging: Every batch undergoes extensive testing, including spectrophotometric analysis for color strength and shade, particle size distribution, moisture content, and heavy metal analysis, adhering strictly to ISO 9001:2015 and REACH standards. Products are then packaged in robust, environmentally friendly container111s, ready for dispatch by our light indigo color exporters.

Our processes leverage state-of-the-art reactors and automated control systems, minimizing human error and ensuring repeatable quality. This stringent approach extends the service life of dyed textiles and enhances performance in target industries like petrochemicals (for protective workwear), metallurgy (high-performance filtration fabrics), and water supply & drainage (industrial-grade textiles requiring corrosion resistance). The emphasis on energy saving throughout our production lifecycle not only reduces our carbon footprint but also translates into a more cost-effective and environmentally conscious product for our partners.

Figure 1: Advanced synthesis reactor for Indigo Blue Vat Blue production.

Technical Specifications and Performance Parameters

Our Indigo Blue Vat Blue is characterized by a precise set of technical parameters that guarantee its superior performance and reliability. These specifications are meticulously maintained through continuous quality assurance, ensuring every batch from our light indigo color factory meets the highest industry benchmarks.

| Parameter | Value / Specification |

|---|---|

| Product Name | Indigo Blue Vat Blue |

| Color Index | C.I. Vat Blue 1 (C.I. 73000) |

| Purity | ≥ 94% (HPLC) |

| Shade | Bright Reddish Blue |

| Physical Form | Powder or Granules |

| Moisture Content | ≤ 0.5% |

| Light Fastness (ISO 105-B02) | 7-8 (Excellent) |

| Washing Fastness (ISO 105-C06) | 4-5 (Very Good to Excellent) |

| Rubbing Fastness (ISO 105-X12, Dry/Wet) | 4-5 / 3-4 (Very Good / Good) |

| Solubility in Water | Insoluble (Forms leuco vat in alkaline reducing bath) |

| pH Stability | Stable in pH 8-12 (Vatting conditions) |

| Dispersibility | Excellent (Fine particle size for uniform dyeing) |

These specifications highlight our product's exceptional chemical stability and performance. The high light and washing fastness scores, determined by international ISO standards, are crucial for end-products requiring long-lasting color integrity, such as denim jeans, workwear, and outdoor textiles. As expert light indigo color manufacturers, we understand that these technical details are paramount for engineers and procurement specialists selecting materials for demanding applications.

Figure 2: Quality assurance and control for Indigo Blue Vat Blue.

Advanced Technical Advantages of Our Indigo Blue Vat Blue

The superior characteristics of our Indigo Blue Vat Blue translate into tangible technical advantages for our clients, enhancing both product quality and operational efficiency. These advantages underscore our position as a preferred light indigo color product provider.

- Exceptional Color Fastness: Our product exhibits outstanding fastness to light, washing, and rubbing, ensuring that dyed materials retain their vibrant blue hue even under harsh conditions. This is critical for high-wear garments like denim and workwear, extending their aesthetic and functional lifespan.

- High Tinting Strength and Purity: The high purity (≥94%) of our Indigo Blue Vat Blue means less dye is required to achieve desired shades, leading to cost savings and reduced chemical load in effluent. Its concentrated form provides deeper, more consistent coloration with fewer applications.

- Superior Levelness and Penetration: The fine particle size and excellent dispersibility ensure uniform dye uptake and penetration into textile fibers. This minimizes uneven dyeing and guarantees a consistent shade across large fabric batches, which is essential for mass production.

- Eco-Friendly Production and Application: Our manufacturing processes are designed for minimal environmental impact, reducing waste and optimizing energy consumption. In application, the stability of the leuco form allows for efficient dyeing, often with reduced water and chemical usage compared to traditional methods. This contributes to energy saving initiatives in textile mills.

- Enhanced Corrosion Resistance (Indirect): While indigo itself doesn't offer corrosion resistance, its stability in various chemical processing environments (e.g., strong alkaline vatting baths) ensures that the dye does not degrade or react unfavorably with equipment. This indirect benefit supports the longevity and maintenance of dyeing machinery, crucial in industrial settings.

- Consistent Batch-to-Batch Quality: Our rigorous quality control protocols, including advanced analytical techniques, ensure that every shipment delivers the same precise shade and performance characteristics. This consistency is vital for maintaining brand reputation and streamlining production processes for our clients.

These advantages collectively offer a compelling value proposition, making our Indigo Blue Vat Blue an optimal choice for manufacturers seeking both high-performance and sustainable dyeing solutions. Our commitment to innovation as a light indigo color company drives these advancements, ensuring our clients receive a product that not only meets but exceeds their expectations.

Application Scenarios and Target Industries

Indigo Blue Vat Blue finds extensive application across a diverse range of industries, driven by its robust color properties and inherent durability. Our expertise as a leading light indigo color company allows us to serve these varied sectors with tailored solutions.

- Textile Industry (Denim & Garments): The most prominent application is in denim manufacturing, where it imparts the characteristic blue hue and fading properties. Our indigo dye is favored by major denim producers for its consistency, depth of color, and excellent wash-down effects. It is also used in other casual wear, workwear, and traditional garments requiring durable blue shades.

- Technical Textiles and Industrial Fabrics: For applications demanding high performance and longevity, such as industrial filters, tarpaulins, and specialized protective clothing, the dye's excellent fastness properties are invaluable. These fabrics often operate in harsh environments, requiring dyes that can withstand exposure to light, abrasion, and industrial washing cycles.

- Pigment and Ink Manufacturing: Beyond textile dyeing, our Indigo Blue Vat Blue is utilized as a high-performance pigment in various formulations, including printing inks, paints, and plastics. Its rich blue color and stability make it a desirable choice for applications where color integrity is paramount.

- Specialty Chemical Formulations: In some niche chemical applications, indigo and its derivatives serve as intermediates or indicators. Its distinct redox properties make it useful in certain analytical or process control scenarios.

The target industries for our Indigo Blue Vat Blue are diverse, including large-scale textile mills, denim wash houses, technical fabric manufacturers, and specialty chemical companies. We work closely with these partners to ensure seamless integration of our light indigo color products into their production lines, providing technical support and customized solutions.

Vendor Comparison and Our Competitive Edge

In a competitive global market, selecting the right light indigo color company is crucial for maintaining product quality, ensuring supply chain stability, and achieving cost efficiencies. While many light indigo color manufacturers exist, our distinct advantages set us apart.

| Feature | Our Indigo Blue Vat Blue | Generic Indigo Dyes (Typical Market) |

|---|---|---|

| Purity (%) | ≥ 94% | Typically 88-92% |

| Light Fastness (ISO 105-B02) | 7-8 | 6-7 |

| Dispersion & Levelness | Excellent, uniform uptake, minimal specking | Good to Moderate, potential for uneven dyeing |

| Batch-to-Batch Consistency | Highly consistent, minimal deviation | Variable, requires more frequent adjustments |

| Environmental Certifications | ISO 14001, REACH Compliant, Oeko-Tex listed | Often limited or less comprehensive |

| Technical Support | Dedicated R&D, on-site assistance, custom solutions | Basic product data, limited customization |

| Supply Chain Reliability | Robust global network, consistent availability | Can be subject to market fluctuations and delays |

Our differentiation stems from an unwavering commitment to quality, backed by significant investments in R&D and manufacturing technology. Unlike some light indigo color suppliers who might prioritize volume over consistency, we ensure that every kilogram of Indigo Blue Vat Blue leaving our facilities meets the highest standards. Our certifications, including ISO 9001, ISO 14001, and compliance with REACH regulations, provide undeniable authoritativeness and trustworthiness to our global partners.

Figure 3: Commitment to quality and environmental stewardship in production.

Customized Solutions and Unparalleled Service Excellence

Recognizing that every client's needs are unique, we offer comprehensive customized solutions and exceptional technical support. As a leading light indigo color company, our commitment extends beyond merely supplying dyes; we partner with our clients to optimize their dyeing processes and achieve desired aesthetic and performance outcomes. Our dedicated R&D team works in close collaboration with clients to address specific challenges.

- Tailored Formulations: We can adjust physical forms (powder, granules) or even develop specific pre-reduced liquid formulations of Indigo Blue Vat Blue to integrate seamlessly with various dyeing machines and processes, from rope dyeing to sheet dyeing.

- Technical Consultation and Optimization: Our team of expert dye chemists and textile technologists provides on-site and remote consultation services. This includes optimizing vatting conditions, evaluating dye uptake, troubleshooting color inconsistencies, and advising on waste treatment strategies. This proactive light indigo color service minimizes downtime and maximizes efficiency.

- Color Matching and Trend Analysis: For clients seeking specific shades or aiming to align with seasonal fashion trends, our colorimetry lab can perform precise color matching and provide guidance on achieving desired effects using our Indigo Blue Vat Blue.

- Regulatory and Compliance Support: Navigating complex international regulations (e.g., REACH, ZDHC, bluesign®) can be challenging. We provide comprehensive documentation and support to ensure our clients' products meet all necessary compliance requirements in their target markets.

This extensive support system ensures that our partners not only receive a premium light indigo color product but also benefit from our deep industry knowledge and technical prowess, fostering long-term, successful collaborations. Our decades of experience in the industry have equipped us to handle diverse technical challenges and provide reliable solutions.

Application Case Studies and Client Success

Our success is measured by the success of our clients. Here are examples illustrating how our Indigo Blue Vat Blue, backed by our expertise as a leading light indigo color company, has delivered tangible value:

- Case Study 1: Denim Mill Efficiency Enhancement

A major denim manufacturer struggled with inconsistent dye uptake and high water consumption in their rope dyeing process. After switching to our Indigo Blue Vat Blue and implementing our recommended vatting protocols, they reported a 15% reduction in dye consumption due to higher purity and better dispersion, and a 10% decrease in water usage due to fewer re-dyeing cycles. Their production efficiency improved by 8%, leading to significant cost savings and reduced environmental footprint. "The consistency of their indigo is unmatched," stated their Head of Production, "it has streamlined our entire operation." - Case Study 2: High-Performance Workwear Durability

A specialized textile company producing workwear for the oil & gas industry required a dye with extreme fastness to light and industrial washing. Their previous supplier's indigo faded prematurely, compromising the perceived quality and longevity of their garments. By adopting our Indigo Blue Vat Blue, they achieved a light fastness rating of 7-8 and a washing fastness of 4-5, exceeding industry standards. This resulted in zero customer complaints related to color fading over a two-year period, significantly boosting their brand's reputation for durability. - Case Study 3: Global Supply Chain Optimization

An international apparel brand needed a consistent supply of high-quality indigo across their factories located in Asia and Europe. They partnered with us, leveraging our robust network of light indigo color exporters. We implemented a synchronized global delivery schedule, ensuring just-in-time inventory for all their production sites. This strategic partnership minimized stock-outs, reduced logistics costs by 7%, and guaranteed uniform product quality regardless of the manufacturing location, thereby enhancing their global operational coherence.

These cases exemplify our capability to deliver not just a superior product, but also a comprehensive service that contributes directly to our clients' bottom line and market leadership. Our commitment to excellence and client satisfaction is a cornerstone of our business philosophy.

Figure 4: Visual representation of consistent color achieved with Indigo Blue Vat Blue.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for an order of Indigo Blue Vat Blue?

A: Standard orders are typically processed and shipped within 7-14 business days, depending on quantity and destination. For large volume or customized orders, our sales team will provide a specific lead time upon quotation. We maintain strategic inventory levels to ensure prompt fulfillment.

Q: Can I request a light indigo color pricelist or a sample?

A: Yes, prospective clients can request detailed pricing information tailored to their specific order volume and delivery requirements. We also offer samples for evaluation; please contact our sales department to arrange for a quotation and sample request.

Q: What are the storage requirements for Indigo Blue Vat Blue?

A: Indigo Blue Vat Blue should be stored in a cool, dry, well-ventilated area, away from direct sunlight and moisture. Keep container111s tightly closed. Under proper storage conditions, the product maintains a stable shelf life of at least 24 months from the manufacturing date.

Q: Is your Indigo Blue Vat Blue compliant with international environmental regulations?

A: Absolutely. Our Indigo Blue Vat Blue is manufactured in compliance with strict international environmental standards, including REACH regulations and is listed on the ZDHC Gateway. We provide all necessary safety data sheets (SDS) and technical data sheets (TDS) to ensure full transparency and compliance.

Q: What kind of after-sales technical support does your light indigo color company offer?

A: We provide comprehensive after-sales support, including direct access to our technical support team for process optimization, troubleshooting, and application guidance. Our experts can provide assistance via phone, email, or even on-site visits if required, ensuring you achieve optimal results with our light indigo color products.

Operational Logistics: Lead Time, Warranty, and Customer Support

Our operational framework is designed to provide maximum reliability and peace of mind for our B2B partners. We understand that timely delivery, robust product assurances, and responsive support are critical for your success.

- Lead Time & Fulfillment: For standard orders of Indigo Blue Vat Blue, we typically maintain a lead time of 7-14 business days from order confirmation to dispatch. Our efficient logistics network, supported by our experienced team of light indigo color exporters, ensures global reach and prompt delivery. We work with trusted freight partners to offer various shipping options, from sea freight for bulk orders to air freight for urgent requirements, optimizing for both cost and speed.

- Warranty Commitments: We guarantee that our Indigo Blue Vat Blue will meet or exceed the published technical specifications and purity levels for a period of 12 months from the date of shipment, provided it is stored and handled according to our recommendations. Our products undergo rigorous quality control, and any deviations from specified parameters are covered by our quality assurance policy, ensuring complete satisfaction for our clients.

- Customer Support: Our dedicated customer support team is available during business hours to assist with order inquiries, technical questions, and logistics coordination. We believe in building long-term relationships through proactive communication and swift problem resolution. For advanced technical challenges, clients have direct access to our R&D specialists. Contact information is readily available on our website and through our sales representatives.

This comprehensive support system underscores our commitment as a dependable light indigo color company, ensuring that our clients receive not just high-quality products, but also a partnership built on trust and reliability.

References

- Christie, R. M. (2007). Colour Chemistry. Royal Society of Chemistry.

- Shenai, V. A. (1993). Technology of Dyeing. Textile Association (India).

- Lewis, D. M. (2014). The Chemistry and Technology of Textile Dyes. Woodhead Publishing.

- Environmental Protection Agency (EPA). (2018). Textile Industry Effluent Guidelines. Retrieved from www.epa.gov

- International Organization for Standardization (ISO). (2015). ISO 9001: Quality Management Systems. Retrieved from www.iso.org

-

Pure Indigo Powder India - Sustainable Natural Dye from India’s Finest Sources

NewsNov.21,2025

-

Synthetic Indigo Powder - Industrial-Grade Dye for Sustainable Textiles & More | Wuxin Group

NewsNov.21,2025

-

Indigo Blue Vat Blue - INNER MONGOLIA WU XIN CHEMICAL CO. LTD

NewsNov.21,2025

-

Vat Blue 1: Durable Eco-Friendly Dye for Global Industry and Humanitarian Use

NewsNov.20,2025

-

Indigo Be – The Future of Modular, Sustainable, and Flexible Solutions

NewsNov.20,2025

-

Dried Indigo Powder: Sustainable Natural Dye for Modern Industries

NewsNov.19,2025

-

Comprehensive Guide to Dye Production: Techniques, Trends & Sustainability

NewsNov.19,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

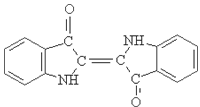

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.