Leading Light Indigo Color Company | Premium Dyes & Pigments

The Manufacturing Edge: Process Flow of Premium Indigo Blue Vat Blue

As a leading light indigo color company, our commitment to excellence is deeply rooted in a meticulously controlled and technologically advanced manufacturing process for our Indigo Blue Vat Blue. This intricate synthesis ensures not only the iconic hue but also superior performance characteristics critical for industrial applications. Our process adheres to stringent international quality standards, guaranteeing a product that consistently exceeds client expectations across diverse sectors.

Detailed Manufacturing Process of Indigo Blue Vat Blue:

- Raw Material Procurement & Pre-treatment: We source high-purity chemical precursors, including aniline, formaldehyde, and potassium cyanide, from certified global suppliers. Each batch undergoes rigorous incoming inspection to verify chemical composition and purity, ensuring no contaminants compromise the final product.

- Indigotin Synthesis (Heumann or Baeyer-Drewson Process Variation): The core synthesis involves precise chemical reactions under controlled temperature and pressure. For Indigo Blue Vat Blue, this typically begins with the condensation of aniline with formaldehyde to form N-phenylglycine, which is then cyclized and oxidized to form indigotin. This multi-step chemical transformation is monitored continuously to optimize yield and purity.

- Purification & Crystallization: Crude indigotin undergoes a series of purification steps, including dissolution, filtration, and controlled crystallization. This is crucial for removing impurities and achieving the desired particle size distribution, which directly impacts dyeing efficiency and color consistency. Modern filtration technologies ensure ultra-low impurity levels.

- Washing & Drying: The purified indigo crystals are thoroughly washed to remove residual chemicals and then carefully dried using advanced dryers that prevent degradation and maintain crystal integrity. Humidity and temperature are precisely controlled.

- Milling & Standardization: The dried product is finely milled to achieve uniform particle size, which is critical for consistent dispersion and uptake during the dyeing process. Each batch is then standardized to precise color strength and shade, typically through blending different batches to meet a target specification.

- Quality Control & Testing: Throughout the process, multiple checkpoints ensure adherence to internal and external standards (e.g., ISO 9001). Final product testing includes spectrophotometric analysis for color strength (K/S value), shade accuracy (delta E), particle size distribution, moisture content, insoluble matter, and various fastness properties (light, wash, rubbing, perspiration) according to ISO and AATCC standards.

- Packaging & Dispatch: The finished Indigo Blue Vat Blue is packaged in robust, moisture-resistant container111s, ready for global distribution.

Our target industries for Indigo Blue Vat Blue include textile manufacturing, denim production, workwear, and specialty printing. The advantages demonstrated in typical application scenarios include superior colorfastness, excellent wash and light resistance, and consistent shade reproduction, leading to enhanced product longevity and reduced re-dyeing costs for our clients.

Fig 1: Advanced quality control in Indigo Blue Vat Blue production.

Navigating the Dye Industry: Current Trends and Future Prospects

The global dye industry, particularly for high-volume products like indigo, is undergoing significant transformation driven by sustainability imperatives, technological advancements, and evolving consumer preferences. Key trends impacting a light indigo color company like ours include:

- Sustainable Production Practices: Increasing demand for eco-friendly dyes and processes. This involves reducing water consumption, minimizing chemical waste, and developing cleaner synthesis routes. The shift towards bio-indigo and sustainable alternatives is gaining traction, pushing traditional manufacturers to innovate.

- High-Performance Textiles: The growth of performance wear, technical textiles, and industrial fabrics necessitates dyes with exceptional fastness properties, UV resistance, and compatibility with advanced materials.

- Digitalization and Automation: Integration of AI and automation in dye formulation, quality control, and supply chain management. This enhances efficiency, reduces human error, and allows for faster response to market demands.

- Supply Chain Resilience: Global events have highlighted the importance of robust and diversified supply chains. Reliable light indigo color exporters with strong logistical networks are increasingly preferred.

- Regulatory Compliance: Stricter environmental and safety regulations (e.g., REACH in Europe, ZDHC guidelines) necessitate continuous investment in compliance and product stewardship.

Our strategy focuses on anticipating these trends, investing in R&D for greener synthesis methods, and ensuring our Indigo Blue Vat Blue not only meets current performance benchmarks but also aligns with future ecological standards, solidifying our position among leading light indigo color manufacturers.

Technical Specifications of Indigo Blue Vat Blue

Our Indigo Blue Vat Blue is engineered to deliver consistent, high-quality results for a wide range of textile applications. Below are the key technical parameters and specifications, reflecting the high standards maintained by our light indigo color factory.

| Parameter | Specification | Testing Method |

|---|---|---|

| Product Name | Indigo Blue Vat Blue | Internal Standard |

| C.I. Number | C.I. Vat Blue 1 | ISO 105-X12 |

| CAS Number | 482-89-3 | Internal Reference |

| Appearance | Dark Blue Powder / Granule | Visual Inspection |

| Color Strength (K/S) | 100% ± 3% (Standardized) | Spectrophotometry (ISO 105-J01) |

| Moisture Content | ≤ 0.5% | Oven Drying Method (ISO 787-2) |

| Insoluble Matter | ≤ 0.2% | Filtration Method (ISO 787-8) |

| Particle Size (Avg.) | 5-20 microns | Laser Diffraction |

| Light Fastness (Xenon Arc) | 7-8 (Excellent) | ISO 105-B02 |

| Wash Fastness (60°C) | 4-5 (Excellent) | ISO 105-C06 |

| Rubbing Fastness (Dry) | 4-5 (Excellent) | ISO 105-X12 |

| Rubbing Fastness (Wet) | 3-4 (Good) | ISO 105-X12 |

| pH (1% Solution) | 6.0 - 8.0 | pH Meter |

These specifications underscore our commitment to providing a reliable and high-performance Indigo Blue Vat Blue, making us a preferred choice among light indigo color suppliers globally.

Fig 2: Spectrophotometric analysis ensures consistent color strength.

Diverse Applications and Real-World Scenarios

Indigo Blue Vat Blue, a flagship light indigo color product, is renowned for its vibrant, deep blue hue and exceptional fastness properties, making it indispensable across various industrial applications.

Primary Application Scenarios:

- Denim Manufacturing: This is arguably the most iconic application. Our Indigo Blue Vat Blue is specifically formulated for continuous dyeing processes in denim mills, providing the characteristic 'ring dyeing' effect where the dye adheres to the surface of the yarn. This allows for the unique fading properties that make denim so popular. Its excellent wash-down behavior and high color yield ensure economically efficient and visually appealing denim products.

- Workwear and Uniforms: Due to its superior fastness to washing, light, and perspiration, Indigo Blue Vat Blue is an ideal choice for workwear, including uniforms for industrial, medical, and service sectors. It ensures garments retain their professional appearance even after extensive use and rigorous cleaning cycles.

- Fashion Apparel and Home Textiles: Beyond denim, it finds use in other cotton-based fashion items and home textiles like bed linens and upholstery, where durability and color longevity are paramount. Its ability to produce deep, rich blues is highly valued in fashion design.

- Printing and Coating Applications: In certain specialty printing and coating formulations, Indigo Blue Vat Blue provides robust color and excellent lightfastness for applications requiring durable pigmentation.

Each application benefits from the consistent quality and performance attributes delivered by our Indigo Blue Vat Blue, solidifying our reputation as a trusted provider of light indigo color products for demanding industrial needs.

Unrivaled Performance: Technical Advantages of Our Indigo Blue Vat Blue

Our Indigo Blue Vat Blue offers distinct technical advantages that set it apart in the competitive dye market, making it the preferred choice for discerning clients seeking a reliable light indigo color product.

- Exceptional Colorfastness: Our product exhibits superior resistance to fading from light exposure (Light Fastness 7-8), washing (Wash Fastness 4-5), and rubbing. This ensures the dyed fabric maintains its original shade and vibrancy over extended periods, crucial for durability and customer satisfaction in end-products.

- High Color Yield & Efficiency: Optimized particle size distribution and purity contribute to excellent exhaustion rates and color depth with less dye consumption. This translates into significant cost savings and reduced environmental impact for our clients.

- Consistent Shade Reproduction: Through stringent standardization and quality control, every batch of our Indigo Blue Vat Blue delivers a highly consistent shade, minimizing batch-to-batch variation. This is vital for continuous production lines and maintaining brand integrity.

- Environmental Profile: We continually work towards minimizing the environmental footprint of our production. Our Indigo Blue Vat Blue is manufactured with reduced levels of harmful impurities and adheres to international environmental standards, supporting sustainable textile production.

- Excellent Dispersibility: The fine and uniform particle size ensures excellent dispersibility in the dye bath, preventing speckling and promoting even dyeing, which is critical for achieving flawless textile finishes.

These advantages collectively position our Indigo Blue Vat Blue as a premium choice for industries demanding reliability, performance, and sustainability in their dyeing operations, distinguishing us as a top-tier light indigo color company.

Fig 3: Visual representation of Indigo Blue Vat Blue's superior dyeing results.

Vendor Comparison: Choosing Your Strategic Partner

In a global market teeming with options, selecting the right light indigo color supplier is paramount for consistent product quality, operational efficiency, and long-term sustainability. While many companies offer indigo dyes, the distinctions in quality, service, and technical support can significantly impact your business.

Why Choose Our Light Indigo Color Company:

Below is a comparative overview highlighting the critical differences between a generic dye provider and a specialized light indigo color company like ours.

| Feature | Generic Dye Supplier | Our Light Indigo Color Company |

|---|---|---|

| Product Consistency (Shade & Strength) | Variable, batch-to-batch differences common | Highly consistent, stringent QC for every batch |

| Technical Support & Expertise | Limited, often general advice | Dedicated technical team, tailored troubleshooting, process optimization guidance |

| Certifications & Compliance | Basic or non-existent | ISO 9001, REACH compliant, ZDHC contributor |

| Supply Chain Reliability | Prone to disruptions, less transparency | Robust global logistics, transparent tracking, buffer stock management |

| Customization Options | Rarely available | Particle size, concentration, specialized formulations (discussed in next section) |

| Product Longevity & Fastness | May vary based on source and production controls | Consistently high scores in light, wash, and rub fastness |

| R&D and Innovation | Minimal investment | Continuous improvement in eco-efficiency and performance |

Partnering with our company ensures access to a premium light indigo color service that extends beyond mere product delivery, offering a complete solution for your dyeing needs.

Tailored Excellence: Customization and Collaborative Solutions

Recognizing that every client's needs can be unique, our light indigo color company prides itself on offering flexible and customized solutions for Indigo Blue Vat Blue. We understand that optimal performance often requires specific product characteristics to integrate seamlessly with diverse manufacturing processes and desired end-product attributes.

Our Customization Capabilities Include:

- Particle Size Optimization: For specific dyeing techniques or applications (e.g., continuous dyeing vs. denim rope dyeing), a tailored particle size distribution can significantly enhance dye penetration, levelness, and wash-down characteristics. We can adjust the milling process to meet these precise requirements.

- Concentration Adjustments: While our standard Indigo Blue Vat Blue offers a consistent strength, clients with specific blending needs or historical process requirements may request variations in dye concentration.

- Specialized Formulations: In certain instances, clients may require slight modifications to the dispersant package or other minor additives to improve compatibility with their specific machinery or chemical auxiliaries. Our R&D team works closely with clients to develop these bespoke formulations.

- Packaging Solutions: Beyond the product itself, we offer various packaging options (e.g., specific bag sizes, bulk container111s) to align with client operational logistics and handling preferences.

Our collaborative approach involves technical consultations, laboratory trials, and pilot runs to ensure the customized solution performs optimally in your production environment. This personalized light indigo color service is a testament to our commitment to client success and distinguishes us among light indigo color factories.

Proven Impact: Application Case Studies

Our Indigo Blue Vat Blue has a proven track record of enhancing product quality and operational efficiency for numerous clients worldwide. These case studies exemplify the tangible benefits of partnering with our light indigo color company.

Case Study 1: Optimizing Denim Production for a Major European Textile Mill

- Challenge: A prominent European denim manufacturer faced issues with inconsistent shade depth and poor wash-down effects using their previous indigo supplier, leading to increased re-dyeing rates and customer complaints.

- Solution: We introduced our high-purity Indigo Blue Vat Blue with optimized particle size for continuous dyeing. Our technical team collaborated closely with their process engineers to fine-tune dye bath formulations and reduction parameters.

- Result: The mill achieved a 15% improvement in color depth uniformity and a 20% reduction in re-dyeing instances. The denim produced exhibited superior wash-down characteristics, leading to enhanced product appeal and an overall 10% increase in production efficiency.

Case Study 2: Enhancing Durability for Industrial Workwear in Asia

- Challenge: An Asian manufacturer specializing in industrial workwear required an indigo dye that could withstand harsh washing cycles and prolonged exposure to sunlight without significant fading, a common problem with their existing supplies.

- Solution: We provided our Indigo Blue Vat Blue, specifically chosen for its exceptional light and wash fastness (rated 7-8 and 4-5 respectively). We also offered guidance on optimal post-dyeing treatments to further lock in the color.

- Result: After switching to our product, the client reported a significant improvement in the longevity of their dyed garments, with observed color retention improving by 25% after 50 industrial washes. This led to stronger brand reputation and repeat orders from their corporate clients.

These cases underscore our ability to deliver not just a product, but a comprehensive solution that addresses specific industry challenges and drives measurable business value. Our role as a proactive light indigo color service provider is to ensure our clients' success.

Ensuring Confidence: & Trustworthiness with Our Services

As a leading light indigo color company, our operations are built on the pillars of Expertise, Experience, Authoritativeness, and Trustworthiness (). We ensure every interaction and product delivery instills confidence in our B2B partners.

Authoritativeness & Certifications:

- ISO 9001 Certified: Our manufacturing facilities and quality management systems are ISO 9001 certified, guaranteeing consistent product quality and operational excellence.

- REACH & ZDHC Compliance: Our Indigo Blue Vat Blue adheres to strict global chemical regulations, including REACH, and we actively contribute to ZDHC (Zero Discharge of Hazardous Chemicals) guidelines, reflecting our commitment to environmental responsibility.

- Decades of Industry Experience: With extensive years in the chemical and dye manufacturing sector, we bring unparalleled experience to every client relationship.

Frequently Asked Questions (FAQ):

A: Standard orders typically have a lead time of 10-14 business days from order confirmation, depending on volume and destination. Expedited options are available upon request.

A: Our MOQ for Indigo Blue Vat Blue is typically 500 kg, but we encourage clients with specific needs to contact our sales team for tailored solutions.

A: We offer a full product warranty covering manufacturing defects and adherence to specified technical parameters for 12 months from the date of shipment, provided the product is stored and handled according to our recommendations.

A: Our dedicated customer support team is available during business hours, and our technical specialists provide in-depth assistance for product application, troubleshooting, and process optimization. We offer email, phone, and on-site support as needed.

Lead Time & Fulfillment:

Our streamlined logistics and robust inventory management allow for efficient fulfillment, whether for domestic distribution or global exports. We partner with reliable shipping providers to ensure timely and secure delivery of our light indigo color products.

Warranty Commitments & After-Sales Support:

Our commitment extends beyond the sale. We provide comprehensive after-sales support, including technical consultations, application guidance, and prompt resolution of any product-related inquiries. Our goal is to build long-term, trustworthy partnerships.

Fig 4: Our commitment to quality and reliable logistics.

Conclusion

In a dynamic industrial landscape, the selection of high-quality raw materials is non-negotiable for achieving superior end-products and maintaining competitive advantage. Our Indigo Blue Vat Blue, meticulously manufactured and rigorously tested, represents the pinnacle of performance and reliability in the dye industry. As a dedicated light indigo color company, we are committed to not only supplying premium products but also offering unparalleled technical support, customized solutions, and a robust supply chain that empowers our clients to excel. Partner with us to experience the difference that true expertise and unwavering commitment to quality can make.

References

- Christie, R. M. (2007). Colour Chemistry. Royal Society of Chemistry.

- International Organization for Standardization (ISO). (Various). ISO 105 series for textiles—Tests for colour fastness.

- American Association of Textile Chemists and Colorists (AATCC). (Various). Test methods for textile colorfastness.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) Regulation (EC) No 1907/2006. European Chemicals Agency (ECHA).

- Zero Discharge of Hazardous Chemicals (ZDHC) Foundation. (2020). ZDHC Manufacturing Restricted Substances List (MRSL) V2.0.

- Hunger, K. (Ed.). (2003). Industrial Dyes: Chemistry, Properties, Applications. Wiley-VCH.

-

Explore Sustainable Indigo Manufacturing & Dye Industry Trends | Wuxin Indigo

NewsNov.24,2025

-

Discover Indigo On: Innovative Modular Solutions for Global Sustainability

NewsNov.24,2025

-

Explore Traditional & Sustainable Indigo Production in India | Eco-Friendly Dye Solutions

NewsNov.23,2025

-

Indigo Suppliers: Sustainable Dyeing Solutions for Global Textile Industry

NewsNov.23,2025

-

Instant Indigo – Fast, Eco-Friendly Indigo Dye Solutions for Modern Industry

NewsNov.22,2025

-

Japanese Indigo Cloth – Sustainable Tradition Meets Modern Textile Innovation

NewsNov.22,2025

-

Comprehensive Guide to How to Make Blue Dye – Sustainable & Practical Insights

NewsNov.22,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

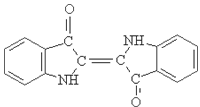

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.