Leading Manufacturers of Synthetic Indigo Powder for Textile and Dyeing Applications

The Rise of Synthetic Indigo Powder Companies A New Era in Textile Dyeing

In the world of textiles, indigo dye holds a special place due to its rich history and vibrant color that has captivated cultures for centuries. Traditionally, natural indigo was derived from the indigo plant, but with the advancements in chemistry, synthetic indigo powder has emerged as a popular alternative. Today, numerous synthetic indigo powder companies are transforming the textile industry by offering innovative, cost-effective, and environmentally sustainable solutions.

Synthetic indigo dye was first synthesized in the late 19th century, revolutionizing the dyeing industry by providing manufacturers with a consistent and stable product. This synthetic version quickly gained popularity owing to its ability to produce the deep blue shades desired by many clothing brands. With its wide availability and lower production costs compared to natural indigo, synthetic indigo gradually became the preferred choice for textile manufacturers around the globe.

One of the key players in this industry is the German chemical giant BASF, which has been instrumental in the production of synthetic indigo. The company’s commitment to quality and sustainability has allowed it to lead the market, catering to the ever-growing demand for indigo dye. BASF’s advancement in synthetic indigo production includes innovative processes that minimize environmental impact while maintaining the dye’s high-performance levels.

Another noteworthy company is Dystar, which specializes in dyeing solutions for textiles. With a strong emphasis on eco-friendly practices, Dystar’s synthetic indigo products cater to the modern consumer’s growing preference for sustainable fashion. They prioritize reducing the environmental footprint of their dyeing processes, employing advanced technologies that consume less water and energy than traditional methods.

synthetic indigo powder companies

In recent years, the global push for sustainability has prompted many synthetic indigo powder companies to focus on developing biodegradable and organic alternatives to traditional synthetic dyes

. Companies such as Archroma are actively engaging in research to create dyes that minimize harm to the environment without compromising on quality or aesthetics. Their efforts reflect a significant shift in the textile industry, where consumers increasingly demand eco-friendly products as part of a broader commitment to sustainability.Moreover, the rise of e-commerce has made it easier for textile manufacturers, especially small and medium businesses, to access synthetic indigo powder. Online platforms allow these companies to source high-quality dyes at competitive prices, leveling the playing field in the industry. This accessibility not only drives innovation but also encourages healthy competition among suppliers, ultimately benefiting consumers with a wider variety of choices.

However, the synthetic indigo production process is not without challenges. Critics argue that while synthetic alternatives may be more cost-effective, there can be environmental concerns related to chemical waste and pollution. As such, leading companies are now investing in research and development to refine their production processes further and reduce their ecological impact.

Looking ahead, the future of synthetic indigo powder companies appears bright. As technology continues to evolve and consumer preferences shift towards sustainable products, businesses that prioritize eco-friendly practices will likely thrive. Collaboration between manufacturers, environmental organizations, and consumers will play a crucial role in driving innovation in the indigo dye sector.

In conclusion, synthetic indigo powder companies are reshaping the textile landscape with their innovative approaches. These companies not only meet the demand for high-quality dyes but also contribute to a more sustainable future for the fashion industry. As awareness of environmental issues grows, the partnership between the textile sector and synthetic dye producers will be essential in creating a balance between fashion and sustainability.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

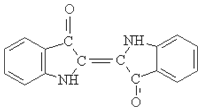

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.