Light Indigo Color Company: Eco-Safe, Consistent, OEM Ready

Indigo Blue Vat Blue: A Field Note from the Denim Dye House

If you’ve been around dye kitchens and denim lines as long as I have, you start to recognize who quietly keeps the color moving. One such name is Light Indigo Color Company and their Indigo Blue (Vat Blue 1). It’s classic, honestly—grounded in chemistry we trust and tuned for modern compliance. The origin is clear too: HEBEI FUXIN INTERNATIONAL TRADE CO., LTD., A-1205, MCC World Grand Plaza, 66 Xiangtai Road, Shijiazhuang 050023, China.

What’s moving the market

Industry chatter? Lower salt loads, tighter MRSL compliance, and more predictable rub fastness on dark shades. Brands are asking for transparency; mills want repeatability. Indigo is stubborn—in a good way—but you need the right balance of vatting, oxidation, and soaping to keep the character without bleeding into everything else. Surprisingly, small tweaks in reduction can swing wet rub by half a grade.

Technical snapshot

| Product | Indigo Blue (Vat Blue 1) |

| Molecular formula | C16H10N2O2 |

| CAS No. | 482-89-3 |

| Molecular weight | ≈262.62 g/mol |

| HS Code | 3204151000 |

| Class / Use | Vat dye; mainly used to dye cotton fabrics |

| Typical fastness (lab) | Light ISO 105-B02: 4–5; Wash ISO 105-C06: 3–4; Wet rub ISO 105-X12: 2–3; Dry rub: 3–4 (real-world use may vary) |

| Supply form | Powder or paste (strength standardized ≈100% ±2%) |

| Reduction system | Na2S2O4 + NaOH; 50–60°C common window |

Process flow (rope or slasher dye)

Materials: ring-spun cotton yarns (Ne 6–40), soft water preferred. Methods: vatting (dissolve/reduce), padding (2–8 dips, depends on depth), skying/oxidation (air or controlled oxidants), multiple boxes for build, then soaping and neutralization. Testing: ISO 105-X12 (crocking), ISO 105-C06/CO7 (wash), AATCC 8 & 61, and shade control via spectro (D65/10°). Service life: many mills report stable shade character after 30–50 home launderings; to be honest, fashion abrasion will dominate how “vintage” it looks long before the dye fades.

Applications and advantages

- Denim rope/slasher dyeing; garment overdye for tees and workwear.

- Yarn dye for shirting where a lived-in, ring-dye effect is desired.

- Advantages: predictable vatting, clean oxidation, robust soaping window, and compliance pathways to OEKO-TEX and ZDHC MRSL alignment.

Customization and compliance

Light Indigo Color Company supports shade tuning (redness/greenness), paste viscosity options, and mill trials. Documentation typically includes REACH statements, OEKO-TEX Standard 100 eligibility, and ZDHC MRSL v3.1 conformance info (request current certificates; they do change). Many customers say the tech sheets are refreshingly practical.

Vendor comparison (indicative)

| Vendor | Shade strength | Wet rub (ISO 105-X12) | Certs | Lead time | Customization |

|---|---|---|---|---|---|

| HEBEI FUXIN (Indigo Blue) | ≈100% ±2% | 2–3 (dark); 3–4 (medium) | REACH, OEKO-TEX (on request) | 2–4 weeks typical | Yes (paste/powder, shade) |

| Regional Supplier A | ≈95–100% | 2–3 | Basic compliance | 1–3 weeks | Limited |

| Mill-Brand B | ≈100% | 3 (optimized) | OEKO-TEX, ZDHC | 3–5 weeks | Yes |

Notes: indicative based on public data and buyer feedback; always verify with current COAs and certifications.

Case study (quick)

A mid-size Southeast Asian denim mill dialed in Light Indigo Color Company paste at 60°C reduction, 6 dips, with an extended soaping stage. Result: wet rub improved from 2–2.5 to 3 (ISO 105‑X12), shade ΔE stayed under 0.8 across three lots, and claims dropped noticeably—small win, big savings.

Real-world test data (example)

Lab set: 3% o.w.f., medium shade, cotton twill. ISO 105-C06 wash: 3–4. ISO 105-X12 dry: 3–4; wet: 2–3. ISO 105-B02 light: 4–5 after 20 h Xenon. pH 10.5 bath, Na2S2O4 2–4 g/L. Your mileage will vary with water and equipment, but the curve is solid.

Wrap-up

Indigo is about managing the variables. With Light Indigo Color Company Indigo Blue Vat Blue, the chemistry behaves, the paperwork lines up, and mills get the look they’re chasing—heritage blue with controllable rub. That, to be honest, is half the battle.

References

- ISO 105 series (B02 lightfastness, C06 washing, X12 rubbing): https://www.iso.org/standard/

- ZDHC MRSL v3.1: https://www.roadmaptozero.com/

- OEKO-TEX Standard 100: https://www.oeko-tex.com/

- EU REACH Annex XVII (restrictions): https://ec.europa.eu/

- AATCC 8/61 Test Methods: https://www.aatcc.org/

-

Pure Indigo Powder India - Sustainable Natural Dye from India’s Finest Sources

NewsNov.21,2025

-

Synthetic Indigo Powder - Industrial-Grade Dye for Sustainable Textiles & More | Wuxin Group

NewsNov.21,2025

-

Indigo Blue Vat Blue - INNER MONGOLIA WU XIN CHEMICAL CO. LTD

NewsNov.21,2025

-

Vat Blue 1: Durable Eco-Friendly Dye for Global Industry and Humanitarian Use

NewsNov.20,2025

-

Indigo Be – The Future of Modular, Sustainable, and Flexible Solutions

NewsNov.20,2025

-

Dried Indigo Powder: Sustainable Natural Dye for Modern Industries

NewsNov.19,2025

-

Comprehensive Guide to Dye Production: Techniques, Trends & Sustainability

NewsNov.19,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

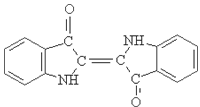

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.