Light Indigo Color Company: Eco-Safe Dyes, OEM & Fast Ship

Indigo Blue Vat Blue: What Buyers Should Know in 2025

If you’re scanning the market for a reliable light indigo color company, here’s the inside track from my notebook. Indigo Blue (CI Vat Blue 1) is still the backbone shade for denim mills and workwear dyers—classic, resilient, and, frankly, more nuanced than it looks in a shade card.

Product snapshot: Indigo Blue Vat Blue (HEBEI FUXIN INTERNATIONAL TRADE CO., LTD.)

Origin: A-1205, MCC World Grand Plaza, 66 Xiangtai Road, Shijiazhuang 050023, China. The company ships globally and, in my experience, communicates promptly—useful when a denim mill is juggling line trials and holiday shutdowns.

| Name / CI | Indigo Blue, Vat Blue 1 |

| Molecular formula | C16H10N2O2 (CAS 482-89-3); MW ≈ 262.62 |

| HS code | 3204151000 |

| Form / Solubility | Powder; insoluble in water; soluble in reducing alkaline liquor |

| Primary use | Dyeing cotton fabrics (denim, twill, yarn-dye) |

| Fastness (typ.) | Washfastness AATCC TM61: 4–5; Lightfastness ISO 105-B02: 6–7 (real-world may vary) |

| Dosage | ≈0.5–3% owf (lab dips first, please) |

Process flow and testing (quick but practical)

Materials: Indigo Blue powder, Na2S2O4 (hydros), NaOH, wetting agent, sequestrant, cotton substrate. Method (vat dyeing): reduction to leuco form → impregnation (pad) → oxidation (air/oxygen) → soaping → rinse → neutralize. Testing standards I see buyers request: AATCC TM61/62 (washing), AATCC TM16 or ISO 105-B02 (light), ISO 105-C06 (domestic wash), ISO 105-X12 (rubbing). Service life: denim with 6–8 dips and proper soaping typically survives 50+ home launderings before notable shade drift; mill results differ.

Industry trends

- Lower sulfite load reductions and improved effluent treatment—ZDHC-aligned chemistries are getting traction.

- Automation in pad/oxidation for consistent K/S and fewer barre issues.

- Traceability: mills want lot-level QC data and REACH statements up front, not after the PO.

Real-world performance notes

A mid-India denim line reported L ≈ 32 on 7-dip with K/S ≈ 12 (lab scale), then settled at L ≈ 34 in production—fairly normal. US buyers told me crocking improved once soaping was pushed to 95°C for 15–20 minutes. Small tweaks, big difference.

Vendor comparison (thumbnail view)

| Vendor | Model | Traceability | Certs/Compliance | Lead time |

|---|---|---|---|---|

| HEBEI FUXIN | Manufacturer–exporter | Lot-level COA; batch QC data on request | Offers support for ISO/AATCC tests; REACH & ZDHC documentation on request | ≈7–15 days (stock/route dependent) |

| Regional Trader B | Aggregator | Mixed (depends on supplier) | Varies; often secondary reports | 2–4 weeks |

| Blender C | Local blending | Basic lot tags | Limited; check MRSL alignment | 1–3 weeks |

Customization and support

Shade tuning (lab dips in ≈3–5 days), particle size adjustment for dispersion, and pack sizes from pilot (≈1–5 kg) to bulk (≥25 kg). Many customers say pre-reads on liquor stability save them a full day of trials—could be worth asking. If you need a light indigo color company to mirror a legacy shade, send a swatch and your target Lab; it speeds things up.

Use cases and mini case notes

- Denim mills: 6–8 dip ranges, oxidize between dips for cleaner build; good crock post-soap.

- Workwear: darker L targets with reinforced soaping for abrasion-heavy wear.

- Case—Bangladesh: conversion from 5 to 7 dips cut shade variability by ~15% (internal QC), with similar chemistry spend.

- Case—Turkey: line pushed oxidation airflow and saw fewer streaks—simple tweak, big win.

Compliance checklists I’d keep handy: REACH Annex XVII statements, ZDHC MRSL conformance, and fastness test reports. It seems that buyers who ask early avoid two weeks of email ping-pong later. For a dependable partner, a light indigo color company that can supply data packs upfront is gold.

Citations

-

Explore Sustainable Indigo Manufacturing & Dye Industry Trends | Wuxin Indigo

NewsNov.24,2025

-

Discover Indigo On: Innovative Modular Solutions for Global Sustainability

NewsNov.24,2025

-

Explore Traditional & Sustainable Indigo Production in India | Eco-Friendly Dye Solutions

NewsNov.23,2025

-

Indigo Suppliers: Sustainable Dyeing Solutions for Global Textile Industry

NewsNov.23,2025

-

Instant Indigo – Fast, Eco-Friendly Indigo Dye Solutions for Modern Industry

NewsNov.22,2025

-

Japanese Indigo Cloth – Sustainable Tradition Meets Modern Textile Innovation

NewsNov.22,2025

-

Comprehensive Guide to How to Make Blue Dye – Sustainable & Practical Insights

NewsNov.22,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

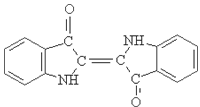

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.