Light Indigo Color Company | OEM, Bulk Supply, Fast Ship

Light Indigo Color Company: Indigo Blue Vat Blue for modern denim lines

Denim is cyclical yet stubbornly timeless. Lately, mills keep asking for cleaner vats, tighter shade control, and less re-dyeing. That’s where Light Indigo Color Company (operated via HEBEI FUXIN INTERNATIONAL TRADE CO., LTD.) has been winning quiet fans with its Indigo Blue Vat Blue—classic chemistry, tuned for today’s QC dashboards.

Product snapshot and specs

Indigo Blue (C.I. Vat Blue 1) is still the denim workhorse. Light Indigo Color Company supplies a consistent, mill-ready grade aimed at rope and slasher dyeing lines.

| Parameter | Value (≈ / notes) |

|---|---|

| Product name | Indigo Blue, Vat Blue 1 |

| Molecular formula | C16H10N2O2 |

| CAS No. | 482-89-3 |

| Molecular weight | 262.62 |

| HS code | 3204151000 |

| Form | Powder or microfine paste (options) |

| Primary use | Cotton fabrics (denim yarn, piece dyeing) |

| Shade | Classic indigo; λmax ≈ 610–620 nm |

| Typical fastness | Wash 4–5; Rubbing dry 4, wet 3–4 (ISO/AATCC; mill results may vary) |

Process flow (what mills actually do)

Materials: Indigo Blue Vat Blue, NaOH (caustic soda), sodium dithionite (hydrosulfite), wetting agent, anti-redeposition aid. Methods vary, but the backbone is consistent.

- Reduction: Indigo → leuco form in alkaline reducing bath (pH ≈ 11–12.5, ORP ≈ −600 to −700 mV).

- Impregnation: Yarn (rope/slasher) passes through multiple dips/skyings for shade build.

- Oxidation: Air or mild oxidant restores the blue chromophore. Rinse sequence controls harshness.

- Soaping/fix: Scour and soap to remove unfixed dye; set handle and brightness.

- QC tests: ISO 105-C06/AATCC 61 (washing), ISO 105-X12/AATCC 8 (rubbing), ISO 105-B02 (light).

- Service life: For midweight denim, color retention ≥ grade 4 over ≈30–50 home washes is common—finishing and enzymes will nudge this.

Where it fits (and why mills pick it)

Applications: rope dyeing for denim, slasher lines for fashion shirtings, garment dyeing trials (yes, some do it), and specialty home textiles. Advantages we keep hearing: predictable reduction behavior, less back-staining, and steadier ΔE across beams. To be honest, that last one saves rework costs.

Vendor comparison (real-world criteria)

| Vendor | Shade stability (ΔE, 3 lots) | ORP window tolerance | Compliance | Notes |

|---|---|---|---|---|

| Light Indigo Color Company | ≈0.6–0.9 | Wide (holds shade with minor ORP drift) | REACH, ZDHC MRSL, OEKO-TEX input support | Good for fast turnarounds |

| Vendor A (generic importer) | ≈1.2–1.6 | Narrow | Basic REACH | Needs tighter bath control |

| Vendor B (local blender) | ≈0.9–1.1 | Medium | Claims ZDHC—check lot docs | Decent economy option |

Customization, QA, and docs

Options: microfine dispersions for stable vats, tailored reduction rates, shade tuning (red-, green-cast), and packaging (25 kg bags, drums). Certifications and testing packs available on request: OEKO-TEX Standard 100 input lists, ZDHC MRSL conformance statements, and batch COAs (assay, moisture, particle size, shade index).

Case notes from the floor

A mid-size mill switched two rope lines to Light Indigo Color Company. After an admittedly tense first week, they reported 18% fewer shade corrections and wet rub improving from 3 to 3–4 (ISO 105-X12) at equal dips. Not headline news, but in denim, that’s real margin.

Industry trends (quick read)

- Cleaner chemistries: ZDHC and brand MRSLs are table stakes.

- Automation: Closed-loop ORP control is spreading; dye must behave across microfluctuations.

- Water/energy cuts: Fewer re-dyes and better soaping chemistry matter more than press releases.

Origin: HEBEI FUXIN INTERNATIONAL TRADE CO., LTD., A-1205, MCC World Grand Plaza, 66 Xiangtai Road, Shijiazhuang 050023, China.

References

- ISO 105-C06: Tests for color fastness to domestic washing — https://www.iso.org/standard/55828.html

- ISO 105-X12: Color fastness to rubbing — https://www.iso.org/standard/55826.html

- ISO 105-B02: Color fastness to artificial light — https://www.iso.org/standard/65234.html

- AATCC 61 & 8 Methods (wash and crocking) — https://www.aatcc.org/

- ZDHC MRSL (current version) — https://www.roadmaptozero.com/

- OEKO-TEX Standard 100 — https://www.oeko-tex.com/

- REACH SVHC guidance — https://echa.europa.eu/regulations/reach

-

Pure Indigo Powder India - Sustainable Natural Dye from India’s Finest Sources

NewsNov.21,2025

-

Synthetic Indigo Powder - Industrial-Grade Dye for Sustainable Textiles & More | Wuxin Group

NewsNov.21,2025

-

Indigo Blue Vat Blue - INNER MONGOLIA WU XIN CHEMICAL CO. LTD

NewsNov.21,2025

-

Vat Blue 1: Durable Eco-Friendly Dye for Global Industry and Humanitarian Use

NewsNov.20,2025

-

Indigo Be – The Future of Modular, Sustainable, and Flexible Solutions

NewsNov.20,2025

-

Dried Indigo Powder: Sustainable Natural Dye for Modern Industries

NewsNov.19,2025

-

Comprehensive Guide to Dye Production: Techniques, Trends & Sustainability

NewsNov.19,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

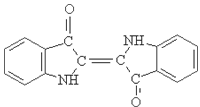

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.