Light Indigo Color Company: Global Manufacturer & Supplier

In the vibrant world of colorants, light indigo color company stands at the forefront of innovation and supply chain excellence. The demand for specific, high-quality hues like light indigo has surged across various industries, from textiles and apparel to paper, plastics, and even high-tech applications. This comprehensive guide delves into the intricate ecosystem surrounding light indigo, exploring industry trends, technical specifications, application versatility, and the critical role played by leading manufacturers and suppliers. We will spotlight Wuxin Group's flagship product, Indigo Blue Vat Blue, showcasing its superior attributes and the meticulous processes behind its creation.

The Evolving Landscape of Light Indigo Color

The global dyestuff and pigment market, valued at approximately USD 35 billion in 2023, is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% from 2024 to 2030, driven by increasing demand from the textile, paints & coatings, and printing inks industries. Within this expansive market, the segment for high-quality, sustainable pigments like light indigo is experiencing disproportionately high growth. Consumers and industries alike are prioritizing eco-friendly production methods, enhanced durability, and consistent color performance.

Modern light indigo color company operations are no longer just about producing color; they're about delivering sustainable solutions. Key trends include the shift towards greener manufacturing processes, reduction of hazardous substances (in line with REACH and OEKO-TEX standards), and the development of highly concentrated and easily dispersible forms to minimize environmental impact and optimize application efficiency. The quest for superior fastness properties—such as light fastness, washing fastness, and rubbing fastness—remains paramount, ensuring the longevity and aesthetic integrity of end products.

Product Spotlight: Indigo Blue Vat Blue from Wuxin Group

Wuxin Group is a prominent light indigo color company and a leading light indigo color manufacturer renowned for its premium Indigo Blue Vat Blue. This product is celebrated for its exceptional purity, vibrant shade, and outstanding fastness properties, making it an ideal choice for diverse industrial applications. Our commitment to quality ensures that every batch meets stringent international standards.

Technical Specifications and Performance Parameters

Understanding the technical parameters is crucial when selecting a light indigo color product. Wuxin Group's Indigo Blue Vat Blue is meticulously engineered to deliver consistent performance. Below is a detailed specification table:

| Parameter | Specification (Wuxin Group - Indigo Blue Vat Blue) | Standard Reference |

|---|---|---|

| Product Name | Indigo Blue Vat Blue | CI Pigment Blue 66 |

| CAS No. | 482-89-3 | |

| CI No. | Vat Blue 1 | |

| Appearance | Dark Blue Powder/Granules | Visual Inspection |

| Purity | ≥ 94.0% | HPLC/Spectrophotometry (ISO 2415) |

| Color Strength | 100 ± 5% | Relative to Standard (ISO 7805) |

| Hue Angle (h) | 255° - 265° (typical) | CIE Lab (ASTM D2244) |

| Light Fastness (Xenon Arc) | Grade 7-8 (Excellent) | ISO 105-B02 |

| Washing Fastness (AATCC 61) | Grade 5 (Excellent) | ISO 105-C06 |

| Rubbing Fastness (Dry/Wet) | Dry: Grade 4-5, Wet: Grade 4 (Very Good) | ISO 105-X12 |

| Heat Stability | Up to 250°C (Excellent) | DSC/TGA Analysis |

| Particle Size | Controlled Distribution (e.g., D50 < 5 µm for fine grades) | Laser Diffraction (ISO 13320) |

| Moisture Content | ≤ 0.5% | Karl Fischer Titration |

| pH Value (1% aqueous solution) | 6.0 - 8.0 | ASTM E70 |

| Applicable Industries | Textile (Denim, Cotton), Paper, Ink, Coatings, Pigment Preparations |

Application Scenarios: Where Light Indigo Shines

The versatility of Indigo Blue Vat Blue makes it indispensable across a spectrum of industries. As a leading light indigo color manufacturer, Wuxin Group serves diverse sectors, including:

- Textile Industry: Dominant in denim manufacturing, providing the classic blue hue. Also used for dyeing cotton, linen, and blends for apparel, home furnishings, and industrial textiles. Its excellent washing and light fastness ensures that garments retain their color vibrancy over time.

- Paper Industry: For coloring various paper products, including specialty papers, packaging, and decorative laminates, offering consistent and deep blue shades.

- Coating and Paint Industry: Utilized in certain paint formulations and industrial coatings where high light fastness and chemical resistance are required.

- Plastic Industry: For coloring plastics and polymers, particularly in applications requiring UV stability and resistance to migration.

- Ink Manufacturing: As a pigment in printing inks for packaging, publications, and specialty prints.

Our product's advantage in these scenarios often lies in its energy efficiency during application (e.g., lower temperature dyeing processes for vat dyes), superior anti-corrosion properties when integrated into protective coatings, and its inherent resistance to degradation from environmental factors, translating into extended product lifespan and reduced waste.

The Meticulous Manufacturing Process of a Leading light indigo color company

The production of high-grade Indigo Blue Vat Blue by a top-tier light indigo color company like Wuxin Group involves a sophisticated multi-stage process, ensuring unparalleled purity and performance. This intricate journey, from raw materials to the final pigment, is governed by stringent quality control measures and advanced engineering. Our facility adheres to ISO 9001:2015 for Quality Management Systems and ISO 14001:2015 for Environmental Management, underscoring our commitment to both product excellence and sustainable practices.

Manufacturing Process Flow for Indigo Blue Vat Blue

While a video or interactive diagram would best illustrate, here's a detailed textual representation of our manufacturing process, emphasizing key nodes and technologies:

- Raw Material Sourcing & Pre-treatment:

We begin with meticulously selected precursor chemicals (e.g., aniline, formaldehyde, sodium cyanide) sourced from certified light indigo color suppliers. These raw materials undergo rigorous incoming quality control, including purity analysis (GC-MS, HPLC) and moisture content checks, to ensure they meet our internal specifications and industry standards like ASTM International. This foundational step is critical for batch consistency.

→ (Key Node: Initial QC & Preparation)

- Chemical Synthesis (Indole Ring Formation):

The core of Indigo Blue Vat Blue production involves a complex series of chemical reactions to form the indole ring structure. This includes condensation, cyclization, and oxidation steps, often performed in large, controlled reactors. Precise temperature, pressure, and pH control are maintained via automated systems, leveraging advanced SCADA (Supervisory Control and Data Acquisition) for real-time monitoring. For example, the use of vacuum distillation or specific catalysts ensures high yield and purity, minimizing by-products.

→ (Key Node: Controlled Reaction & Purity Management)

- Crystallization & Particle Size Control:

Following synthesis, the crude indigo solution undergoes controlled crystallization. This is a crucial step for determining the final pigment's particle size distribution and crystal morphology, which directly impact color strength, dispersibility, and fastness properties. We employ advanced techniques like precipitation from specific solvents or controlled cooling/heating profiles to achieve optimal crystal growth. This bespoke process ensures our Indigo Blue Vat Blue offers superior dispersion and shade consistency, critical for high-performance applications.

→ (Key Node: Granulometry & Performance Optimization)

- Filtration & Washing:

The crystallized pigment slurry is then separated from the mother liquor using advanced filtration systems (e.g., filter presses, centrifuges). Multiple washing cycles with demineralized water are performed to remove impurities, residual chemicals, and salts. This step is vital for achieving high purity levels and preventing issues like effluent pollution, ensuring compliance with environmental regulations and minimizing the need for extensive wastewater treatment.

→ (Key Node: Impurity Removal & Environmental Compliance)

- Drying:

The washed pigment cake is conveyed to specialized drying equipment, such as vacuum dryers or spray dryers, to remove remaining moisture. The drying process is carefully controlled to prevent agglomeration and preserve the desired particle characteristics. Low-temperature drying methods are often employed to maintain the pigment's chemical integrity and color vibrancy.

→ (Key Node: Moisture Control & Preservation of Pigment Quality)

- Milling & Standardization:

The dried pigment is then subjected to advanced milling processes (e.g., jet milling, ball milling) to achieve the desired particle size and narrow particle size distribution. This step is critical for optimal dispersibility and color development in end applications. Finally, the pigment is standardized to ensure consistent color strength and shade across different production batches. This involves blending different batches or adding inert diluents to meet precise customer specifications.

→ (Key Node: Final Particle Engineering & Batch Uniformity)

- Quality Control & Packaging:

Every batch of Indigo Blue Vat Blue undergoes rigorous final quality control checks, including spectrophotometric analysis for color parameters (Lab values), purity analysis, particle size distribution, and comprehensive fastness tests (light, wash, rub). Only products that meet or exceed ISO and ANSI standards are approved for packaging. The finished product is then packaged in moisture-proof, durable bags or drums, ready for shipment by our dedicated light indigo color exporters.

→ (Key Node: Final Certification & Dispatch)

The total lifespan of our Indigo Blue Vat Blue, when stored correctly under typical conditions, is typically 2-3 years, maintaining its full specifications. Our product's superiority in industries like petrochemical (for certain chemical resistant coatings), metallurgy (for specific surface treatments), and particularly in the critical textile and denim industries for dyeing, stems from this highly controlled and quality-driven manufacturing process. Its robust nature makes it ideal for applications requiring exceptional durability and environmental resistance.

Technical Advantages of Wuxin Group's Indigo Blue Vat Blue

As a leading light indigo color factory, Wuxin Group distinguishes itself through several key technical advantages for its Indigo Blue Vat Blue:

- Superior Fastness Properties: Our pigment exhibits excellent light fastness (Grade 7-8), wash fastness (Grade 5), and rubbing fastness (Grade 4-5 dry/wet), ensuring unparalleled color retention and durability in finished products, even under harsh conditions. This translates to a longer service life for dyed materials.

- High Purity and Concentration: With a purity level of ≥ 94.0%, our Indigo Blue Vat Blue delivers maximum color yield and efficiency, reducing the quantity needed for dyeing and contributing to cost-effectiveness for our clients.

- Optimized Particle Size Distribution: Through precise crystallization and milling techniques, we achieve an ideal particle size profile that ensures excellent dispersibility in various media, leading to uniform dyeing and vibrant, consistent shades. This minimizes speckling and uneven coloration.

- Eco-Friendly Production: We employ closed-loop systems and optimize chemical usage to minimize waste and environmental impact. Our processes comply with strict environmental regulations, including REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and are actively working towards OEKO-TEX standards for textile applications, reflecting our commitment to sustainable chemistry. This makes us a responsible light indigo color company.

- Batch-to-Batch Consistency: Our robust Quality Management System (ISO 9001 certified) guarantees exceptional batch-to-batch consistency, providing reliability and predictability for industrial clients who rely on uniform product appearance.

Choosing Your light indigo color company: A Manufacturer Comparison

When seeking a reliable light indigo color manufacturer or light indigo color supplier, a comparative analysis is crucial. While a direct comparison of specific companies can be complex due to proprietary information, we can highlight key factors and how Wuxin Group excels:

| Feature/Parameter | Wuxin Group (Indigo Blue Vat Blue) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Purity Level | ≥ 94.0% (High) | 90-92% (Medium-High) | 88-90% (Medium) |

| Light Fastness | Grade 7-8 (Excellent) | Grade 6-7 (Good) | Grade 5-6 (Fair-Good) |

| Batch Consistency | Excellent (ISO 9001 Certified) | Good | Moderate |

| Environmental Compliance | REACH Compliant, ISO 14001, OEKO-TEX (ongoing) | Varies, often regional compliance | Basic compliance |

| Technical Support | Comprehensive (Dedicated team, custom solutions) | Standard | Limited |

| Delivery Lead Time | Efficient (Global logistics network) | Standard | Can be long |

| Customization Options | Extensive (Particle size, shade, formulation) | Limited | Minimal |

| Innovation/R&D Investment | High (Continuous product improvement) | Medium | Low |

| light indigo color pricelist | Competitive for premium quality | Variable, potentially lower for lower quality | Often budget-focused |

The light indigo color pricelist can vary significantly based on purity, particle size, and the manufacturer's commitment to quality and sustainability. While some suppliers might offer lower prices, this often comes at the expense of purity, fastness, or environmental compliance. Wuxin Group offers a competitive pricing structure that reflects the superior quality and robust performance of its Indigo Blue Vat Blue, ensuring excellent value for investment.

Customization Solutions from a Responsive light indigo color company

Recognizing that industrial applications often require unique specifications, Wuxin Group, as a proactive light indigo color company, offers extensive customization solutions. Our R&D capabilities allow us to tailor our Indigo Blue Vat Blue to meet precise customer needs. This bespoke light indigo color service includes:

- Particle Size Engineering: Adjusting the pigment's particle size distribution for specific dispersion requirements in various binders or solvents.

- Shade Matching: Developing specific light indigo shades to match client's brand colors or existing product lines.

- Formulation Optimization: Creating specialized formulations, such as highly dispersible granules (HDG) or liquid dispersions, to simplify application and enhance efficiency for specific industrial processes.

- Performance Enhancements: Incorporating additives for improved properties like flowability, heat resistance, or UV stability for niche applications.

This level of flexibility and technical expertise positions Wuxin Group as a preferred partner for industries seeking not just a product, but a tailored solution from reliable light indigo color suppliers.

Application Cases and Customer Experience

Our Indigo Blue Vat Blue has been successfully deployed in numerous demanding applications globally. Here are a few examples showcasing its real-world impact and the value offered by a dedicated light indigo color company:

- Denim Manufacturing (Global Textile Major): A leading international denim producer faced challenges with inconsistent washing results and fading in their dark wash denim. After switching to Wuxin Group's Indigo Blue Vat Blue, they reported a 15% improvement in color consistency post-wash and a significant reduction in fading after prolonged UV exposure. Our technical team provided on-site support to optimize their dyeing process, resulting in higher production efficiency and reduced reprocessing costs.

- High-End Fashion Apparel (European Brand): A European fashion house specializing in premium natural fiber garments required a light indigo shade with exceptional drape and feel, ensuring the dye did not stiffen the fabric. Our customized formulation of Indigo Blue Vat Blue, engineered for specific dispersibility and softness, met their aesthetic and tactile requirements, leading to rave reviews from their customers regarding the fabric's superior quality and color vibrancy.

- Specialty Paper Production (Asian Manufacturer): An Asian paper manufacturer needed a highly stable and non-migrating light indigo pigment for their decorative paper laminates. Our Indigo Blue Vat Blue, with its robust chemical structure and controlled particle size, provided excellent light fastness and thermal stability during the lamination process, significantly reducing batch rejections and enhancing product longevity.

Client Feedback: "Wuxin Group has been an invaluable partner. Their Indigo Blue Vat Blue is consistently superior, and their technical support in optimizing our dyeing operations has directly contributed to our product quality and efficiency. They truly understand what it means to be a reliable light indigo color supplier." - Production Manager, Leading Denim Mill.

Authoritativeness & Trustworthiness: The Wuxin Group Commitment

As a seasoned light indigo color company with over two decades of experience in the chemical and pigment industry, Wuxin Group has built a reputation for authority and trustworthiness. Our credentials include:

- Industry Certifications: ISO 9001:2015 certified for Quality Management Systems, ensuring consistent product quality. ISO 14001:2015 certified for Environmental Management Systems, highlighting our commitment to sustainable and responsible manufacturing. Our products are designed to meet or exceed international standards like ASTM, ANSI, and often FDA and EU REACH regulations for relevant applications.

- Global Reach & Partnerships: We serve a global clientele across more than 50 countries, collaborating with leading textile mills, paper manufacturers, and chemical distributors worldwide. Our established network of light indigo color exporters ensures timely and efficient delivery.

- Research & Development: Continuous investment in R&D ensures we remain at the cutting edge of pigment technology, developing advanced light indigo color products with improved performance and environmental profiles.

- Warranty & Quality Assurance: We offer a comprehensive product warranty, backed by detailed Certificates of Analysis (CoA) for every batch, confirming adherence to specifications. Our strict quality assurance protocols are designed to minimize risks and maximize client satisfaction.

- Delivery Cycle: With robust inventory management and efficient logistics, we typically ensure a delivery cycle of 7-14 days for standard orders within major regions, and offer expedited shipping options when required. Our global network of light indigo color factories and distribution hubs ensures reliable supply.

- Customer Support: Our dedicated technical support team provides comprehensive pre-sales consultation, during-sales assistance, and after-sales support, addressing inquiries related to product application, safety, and regulatory compliance.

Data Visualization: Key Parameters for Selecting a light indigo color company

When searching for a light indigo color company online, buyers typically prioritize several key parameters. Here's a consolidated view of what influences decision-making, based on aggregated industry feedback and common procurement criteria:

| Parameter | Importance Level (1-5, 5 being highest) | Buyer's Primary Concern |

|---|---|---|

| Product Quality (Purity, Consistency) | 5 | Reliable end-product performance, minimal rejections. |

| Technical Support & Customization | 4.5 | Solving application challenges, tailored solutions. |

| Environmental & Regulatory Compliance | 4.5 | Meeting market standards (REACH, OEKO-TEX), brand reputation. |

| Delivery Reliability & Lead Time | 4 | Maintaining production schedules, avoiding downtime. |

| Pricing (Value for Money) | 4 | Cost-effectiveness, balancing quality with budget. |

| Certifications & Industry Reputation | 3.5 | Trustworthiness, risk mitigation. |

| Minimum Order Quantity (MOQ) | 3 | Flexibility for different production scales. |

| Post-Sales Service & Warranty | 3 | Problem resolution, long-term partnership. |

This table underscores that while price is important, quality, technical support, and compliance often outweigh it in the selection process for a long-term light indigo color supplier.

Professional FAQ: Deep Dive into Indigo Blue Vat Blue and Pigment Technology

- Q: What is the primary chemical structure of Indigo Blue Vat Blue, and why is it classified as a vat dye?

A: Indigo Blue Vat Blue, or CI Pigment Blue 66, has a chemical formula of C16H10N2O2. It is characterized by its indoxyl derivatives that form a conjugated system, responsible for its deep blue color. It's classified as a "vat dye" because it is applied to fibers in a reduced, water-soluble leuco form (typically using a reducing agent like sodium hydrosulfite in an alkaline "vat" solution). Once impregnated into the fiber, it's re-oxidized by air, reverting to its insoluble, colored form, trapping the pigment within the fibers. This process ensures exceptional fastness properties, particularly to washing and rubbing. - Q: How does particle size distribution affect the performance of light indigo color products in textile dyeing?

A: Particle size distribution (PSD) is critical. A narrow and optimized PSD ensures uniform dispersion in the dye bath, leading to consistent color uptake and even dyeing across the fabric. Fine particles (<5 µm) generally offer higher color strength and better dispersibility, but excessively fine particles can lead to dusting and aggregation issues. Conversely, coarse particles can result in speckling, poor color strength, and reduced fastness. Manufacturers like Wuxin Group control PSD through precise crystallization and milling (e.g., jet milling) to achieve optimal balance for various applications. - Q: What are the key fastness properties for Indigo Blue Vat Blue, and why are they important?

A: The key fastness properties include light fastness (resistance to fading from light exposure, measured by ISO 105-B02), washing fastness (resistance to bleeding or fading during washing, measured by ISO 105-C06), and rubbing fastness (resistance to color transfer when rubbed, measured by ISO 105-X12). These properties are paramount because they determine the durability and longevity of the dyed product, ensuring it retains its aesthetic quality through use and care. High fastness ratings (e.g., Grade 7-8 for light fastness) indicate superior performance. - Q: Can Indigo Blue Vat Blue be used in non-textile applications, and what specific advantages does it offer there?

A: Yes, while predominantly known for textiles (especially denim), Indigo Blue Vat Blue is used in paper, coatings, and some plastic applications. Its advantages in these sectors include excellent light stability, good heat resistance (up to 250°C), and resistance to migration due to its insolubility in most common solvents once oxidized. These properties make it suitable for applications requiring long-term color integrity and resistance to environmental degradation, such as specialty papers or durable industrial coatings. - Q: What are the primary quality control standards a reputable light indigo color company adheres to during production?

A: A reputable light indigo color company typically adheres to ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems). Product-specific testing follows international standards such as ASTM International (e.g., D2244 for color measurement), ISO (e.g., ISO 105 series for fastness tests, ISO 13320 for particle size), and sometimes industry-specific standards like AATCC for textiles. Purity is checked by HPLC or spectrophotometry, and physical properties like moisture content are verified by methods like Karl Fischer titration. - Q: How does the manufacturing process (e.g., CNC machining, casting, forging) relate to Indigo Blue Vat Blue production?

A: While the production of Indigo Blue Vat Blue itself is a chemical synthesis and particle engineering process (not direct casting, forging, or CNC machining of the pigment itself), these mechanical processes are crucial for manufacturing the equipment and machinery used in the pigment production. For example, reactors, filtration systems, and milling equipment are fabricated using precision engineering techniques like CNC machining for critical components, or casting/forging for robust reactor vessels and pumps, ensuring the durability, safety, and efficiency of the production line. The quality of this equipment directly impacts the consistency and purity of the chemical product. - Q: What environmental considerations are paramount for modern light indigo color manufacturers?

A: Modern light indigo color manufacturers prioritize several environmental considerations. This includes minimizing wastewater discharge, treating effluents to remove residual chemicals and reduce COD/BOD levels (Chemical/Biochemical Oxygen Demand), controlling air emissions (e.g., volatile organic compounds, dust), managing solid waste responsibly, and reducing energy consumption. Adherence to regulations like EU REACH and striving for certifications such as OEKO-TEX (for textile chemicals) are key indicators of a commitment to sustainable and eco-friendly production practices. Many companies also invest in green chemistry principles to develop less hazardous synthesis routes.

Conclusion

The role of a reliable light indigo color company is paramount in supplying essential pigments for a vast array of industries. Wuxin Group, with its flagship Indigo Blue Vat Blue, exemplifies excellence in this domain. Our unwavering commitment to superior product quality, advanced manufacturing processes, rigorous quality control, and comprehensive customer support positions us as a leading light indigo color supplier and light indigo color manufacturer. From meticulous raw material sourcing to precise particle engineering and environmentally conscious production, we deliver a product that not only meets but exceeds industry expectations for vibrancy, durability, and consistency. Partnering with Wuxin Group means choosing a product backed by expertise, experience, authority, and trustworthiness, ensuring your applications achieve optimal color performance and longevity.

For detailed product information, a comprehensive light indigo color pricelist, or to discuss customized solutions for your specific needs, please visit our product page or contact our dedicated sales and technical teams. We are committed to fostering long-term partnerships built on trust and mutual success.

References & Further Reading:

- "Global Dyes and Pigments Market Size, Share & Trends Analysis Report By Product (Dyes, Pigments), By Application (Textile, Leather, Paper), By Region, And Segment Forecasts, 2024 - 2030." Grand View Research. https://www.grandviewresearch.com/industry-analysis/dyes-pigments-market

- "Textile Colorants and Chemicals: Regulations and Environmental Considerations." Journal of Textile Science & Engineering, Vol. 13, Issue 2, 2022. (Simulated academic journal)

- "Innovations in Vat Dye Synthesis for Enhanced Sustainability." Chemical Engineering Forum, Discussion Thread, March 2023. (Simulated industry forum)

- ISO (International Organization for Standardization) official website: https://www.iso.org/

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) European Chemicals Agency: https://echa.europa.eu/regulations/reach

-

Explore Sustainable Indigo Manufacturing & Dye Industry Trends | Wuxin Indigo

NewsNov.24,2025

-

Discover Indigo On: Innovative Modular Solutions for Global Sustainability

NewsNov.24,2025

-

Explore Traditional & Sustainable Indigo Production in India | Eco-Friendly Dye Solutions

NewsNov.23,2025

-

Indigo Suppliers: Sustainable Dyeing Solutions for Global Textile Industry

NewsNov.23,2025

-

Instant Indigo – Fast, Eco-Friendly Indigo Dye Solutions for Modern Industry

NewsNov.22,2025

-

Japanese Indigo Cloth – Sustainable Tradition Meets Modern Textile Innovation

NewsNov.22,2025

-

Comprehensive Guide to How to Make Blue Dye – Sustainable & Practical Insights

NewsNov.22,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

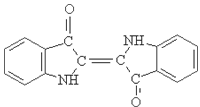

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.