Light Indigo Color Company: Premium Pigments, Dyes & Solutions

Understanding the Modern Dye Industry and Light Indigo Color Applications

The global dyestuff market is experiencing robust growth, driven by increasing demand from the textile, paper, leather, and coatings industries. Within this dynamic landscape, the prominence of indigo dyes, particularly for denim and cotton applications, remains unparalleled. As a leading light indigo color company, we specialize in the production and supply of high-purity Indigo Blue Vat Blue, a cornerstone pigment for creating classic and contemporary light indigo shades. Our commitment extends to delivering advanced dyeing solutions that align with evolving industry standards for sustainability, efficiency, and color fastness.

Industry trends indicate a significant shift towards eco-friendly production methods and dyes with superior environmental profiles. This includes demand for pigments with lower heavy metal content, reduced COD/BOD in wastewater, and improved biodegradability. Furthermore, textile manufacturers are increasingly seeking dyes that offer exceptional batch-to-batch consistency and ease of application, critical for maintaining brand integrity and optimizing production costs. Our Indigo Blue Vat Blue product is engineered to meet these stringent requirements, ensuring a reliable supply of high-performance colorants for discerning B2B clients globally.

Manufacturing Process of Indigo Blue Vat Blue

The production of Indigo Blue Vat Blue by a specialized light indigo color company involves a sophisticated multi-stage chemical synthesis and processing workflow, ensuring high purity and consistent performance. Our process adheres to stringent quality control protocols, from raw material inspection to final product packaging.

Detailed Process Flow:

- Raw Material Sourcing and Preparation: We begin with high-quality precursors such as N-phenylglycine, sodium amide, and formaldehyde derivatives. These materials undergo rigorous quality checks to ensure they meet our purity specifications, critical for initiating the synthesis of indigo intermediates.

- Indole Derivative Synthesis: The primary synthesis involves complex chemical reactions, often initiated by alkali fusion of N-phenylglycine to form indoxyl, which is then oxidized to indigo. This stage requires precise temperature and pressure control to optimize reaction yield and minimize impurities.

- Oxidation and Condensation: The indoxyl intermediate is carefully oxidized and undergoes dimerization to form the insoluble Indigo Blue pigment. This step is crucial for achieving the characteristic deep blue color.

- Vatting (Reduction): For dyeing applications, insoluble indigo must be converted into its soluble leuco form. This reduction process, known as vatting, typically involves an alkaline medium and reducing agents like sodium dithionite (hydrosulfite). Modern techniques also include electrochemical reduction for a cleaner process.

- Purification and Filtration: Post-synthesis, the crude indigo undergoes multiple purification steps, including washing and filtration, to remove unreacted raw materials, by-products, and soluble salts. This ensures the final product's high purity and enhances its dyeing performance.

- Standardization and Particle Size Control: The purified indigo paste is then standardized for concentration and dispersibility. Particle size control, often achieved through fine milling or micronization, is vital for achieving uniform dyeing, excellent dispersion in the dye bath, and superior color strength.

- Drying and Packaging: The indigo product is dried using advanced techniques (e.g., spray drying or vacuum drying) to produce powder or granular forms. Each batch is carefully packaged in moisture-proof container111s, ready for distribution as a premium light indigo color product.

Testing Standards and Quality Assurance:

All our Indigo Blue Vat Blue batches are subjected to rigorous testing against international standards such as ISO (e.g., ISO 105 series for color fastness) and relevant industry specifications. Our internal QC system includes spectrophotometric analysis for shade consistency, purity assays (HPLC), and tests for dyeing properties like reduction potential, stability, and compatibility. This commitment to quality ensures a service life characterized by consistent performance in diverse dyeing applications.

Technical Specifications and Performance Advantages

Our Indigo Blue Vat Blue, supplied by a leading light indigo color company, is formulated for superior performance in demanding industrial applications. The technical specifications below highlight the key parameters that ensure its effectiveness and reliability.

Product Specification: Indigo Blue Vat Blue

| Parameter | Specification | Test Method |

|---|---|---|

| Color Index Generic Name | Vat Blue 1 | ISO 105-J01 |

| CAS No. | 482-89-3 | N/A |

| Purity | ≥ 94% | HPLC |

| Appearance | Dark Blue Powder/Granules | Visual |

| Moisture Content | ≤ 1.0% | Karl Fischer |

| Water Solubility (Leuco Form) | Excellent | Empirical Test |

| Color Fastness to Light (ISO 105-B02) | 7-8 (Excellent) | ISO Standard |

| Color Fastness to Washing (ISO 105-C06) | 4-5 (Very Good) | ISO Standard |

| Tinctorial Strength | 100% (Standard) | Spectrophotometry |

Technical Advantages and Applications:

- Exceptional Color Fastness: Our Indigo Blue Vat Blue delivers outstanding resistance to fading from light, washing, and rubbing, making it ideal for high-wear textiles like denim and workwear. This ensures the longevity and aesthetic appeal of finished products.

- Vibrant and Consistent Shade: The product yields a brilliant, deep blue hue that can be precisely controlled to achieve various shades of light indigo. Its consistent particle size and high purity guarantee batch-to-batch uniformity, critical for large-scale textile production.

- Broad Application Spectrum: Beyond traditional denim, this light indigo color product is effectively utilized in dyeing cotton, wool, silk, and blends for apparel, home furnishings, and industrial textiles. Its versatility also extends to pigment applications in inks and coatings.

- Eco-Friendly Profile: Manufactured with environmental considerations, our Indigo Blue Vat Blue offers a relatively favorable ecological footprint compared to many synthetic dyes. This aligns with modern sustainability initiatives within the textile industry.

- High Tinctorial Strength: Its strong coloring power means less dye is required to achieve desired depths of shade, leading to cost efficiencies for textile mills and pigment manufacturers.

Vendor Comparison and Customized Solutions

When evaluating light indigo color suppliers, B2B decision-makers prioritize not only product quality but also reliability, technical support, and the ability to provide tailored solutions. As one of the leading light indigo color manufacturers, we differentiate ourselves through a comprehensive approach to customer partnership.

Why Choose Our Light Indigo Color Company?

| Feature/Aspect | Our Light Indigo Color Company | Typical Competitor |

|---|---|---|

| Purity of Indigo Blue Vat Blue | ≥ 94% (consistently high) | Typically 90-93% (variable) |

| Color Fastness (Light) | ISO 7-8 (Excellent) | ISO 6-7 (Good) |

| Particle Size Uniformity | Micronized for optimal dispersion | Standard milling (less uniform) |

| Technical Support | Dedicated chemists and application engineers | Limited or basic support |

| Customization Capabilities | Custom formulations, particle sizes, packaging | Generally off-the-shelf products |

| Certifications | ISO 9001, REACH compliant, bluesign® readiness | Basic ISO certification |

Customized Solutions for Specific Needs:

We understand that specific applications may require unique dye characteristics. Our R&D team works closely with clients to develop customized Indigo Blue Vat Blue solutions, including:

- Tailored Particle Size Distributions: For specific dispersion requirements in textile printing pastes or specialized coatings.

- Enhanced Purity Grades: For highly sensitive applications such as medical textiles or fine art pigments, where even minimal impurities are unacceptable.

- Specific Formulations: Adjustments to pH, dispersibility, or redox potential for compatibility with particular dyeing machines or processes.

- Packaging Variations: From bulk container111s for large-scale operations to smaller, specific weight packaging for specialty users.

Application Case Studies and Customer Success

Our role as a trusted light indigo color company is reinforced by the tangible successes of our clients across diverse industries. We provide comprehensive light indigo color service, ensuring optimal results from initial consultation to post-delivery support.

Case Study 1: Denim Manufacturer Enhances Sustainability and Color Consistency

A major denim producer, struggling with batch-to-batch color variation and high wastewater treatment costs from their existing indigo supplier, partnered with us. We introduced our high-purity Indigo Blue Vat Blue, along with technical recommendations for optimized dyeing protocols. The result was a remarkable 15% reduction in dye consumption due to higher tinctorial strength and superior dispersion. More importantly, consistent shade matching was achieved across 98% of production batches, significantly reducing re-dyeing and associated resource waste. This partnership solidified our position as reliable light indigo color exporters for high-volume industries.

Case Study 2: Specialty Pigment Producer Achieves Advanced Formulation

A specialty pigment manufacturer sought an ultra-fine, highly dispersible Indigo Blue Vat Blue for a new range of premium inks and coatings. Their existing supplier’s product presented issues with agglomeration and inconsistent color yield in solvent-based systems. Our R&D team collaborated to develop a custom micronized Indigo Blue Vat Blue with enhanced surface properties. This bespoke light indigo color product enabled the client to achieve unparalleled color depth, brilliance, and stability in their end products, opening new market segments and boosting their competitive edge.

Customer Testimonial:

"Partnering with this light indigo color company transformed our denim dyeing process. The consistency and quality of their Indigo Blue Vat Blue are unmatched, leading to significant cost savings and a more sustainable operation. Their technical team's support was invaluable in optimizing our dyeing recipes." - Head of Production, Global Textile Group.

Trust, Support, and Logistics

As a reputable light indigo color company, we prioritize transparency, reliability, and unparalleled customer support to build lasting partnerships.

Frequently Asked Questions (FAQ):

-

Q: What forms of Indigo Blue Vat Blue do you offer?

A: We primarily supply Indigo Blue Vat Blue in powder and granular forms, optimized for easy handling and dispersion in industrial dyeing processes.

-

Q: What is the typical lead time for orders?

A: Standard orders are typically fulfilled within 7-14 business days, depending on volume and destination. Expedited options are available upon request. For custom formulations, lead times will be discussed during the project scoping phase.

-

Q: Do your products comply with international environmental regulations?

A: Yes, our Indigo Blue Vat Blue is REACH compliant and meets stringent environmental standards, aligning with initiatives like the ZDHC Roadmap and bluesign® system for safer chemistry.

-

Q: What kind of technical support do you provide?

A: Our team of experienced chemists and application engineers offers comprehensive technical support, including product selection guidance, optimization of dyeing recipes, troubleshooting, and on-site assistance for large-scale projects.

Lead Time and Fulfillment:

Our robust supply chain and efficient logistics ensure timely delivery of your light indigo color products. We work with trusted freight partners to manage global shipments, offering competitive pricing and transparent tracking. Emergency orders can often be accommodated through our expedited processing capabilities.

Warranty and After-Sales Support:

All our Indigo Blue Vat Blue products come with a standard quality guarantee, ensuring they meet the specified technical parameters. In the unlikely event of any product non-conformity, our dedicated customer service team provides prompt investigation and resolution, upholding our commitment to client satisfaction. Our after-sales support extends to continuous technical advice and performance monitoring, reinforcing our role as a long-term partner.

References

- Bouttaz, H. (2018). The Chemistry of Dyes and Pigments. Royal Society of Chemistry.

- Colour Index International. (Ongoing). Society of Dyers and Colourists and American Association of Textile Chemists and Colorists.

- Peters, R. H. (1967). Textile Chemistry. Elsevier Publishing Company.

- European Chemicals Agency (ECHA). (Ongoing). REACH Regulation (EC) No 1907/2006.

- Textile Exchange. (Ongoing). Material Change Index.

-

Pure Indigo Powder India - Sustainable Natural Dye from India’s Finest Sources

NewsNov.21,2025

-

Synthetic Indigo Powder - Industrial-Grade Dye for Sustainable Textiles & More | Wuxin Group

NewsNov.21,2025

-

Indigo Blue Vat Blue - INNER MONGOLIA WU XIN CHEMICAL CO. LTD

NewsNov.21,2025

-

Vat Blue 1: Durable Eco-Friendly Dye for Global Industry and Humanitarian Use

NewsNov.20,2025

-

Indigo Be – The Future of Modular, Sustainable, and Flexible Solutions

NewsNov.20,2025

-

Dried Indigo Powder: Sustainable Natural Dye for Modern Industries

NewsNov.19,2025

-

Comprehensive Guide to Dye Production: Techniques, Trends & Sustainability

NewsNov.19,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

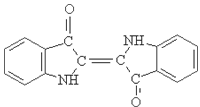

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.