Light Indigo Color Company: Premium Pigments & Dyes

Strategic Sourcing of High-Quality Light Indigo Dyes

In the dynamic global market for industrial dyes, securing a reliable supply of premium light indigo color company products is paramount for manufacturers across various sectors. The demand for consistent quality, exceptional fastness, and environmentally compliant production drives innovation among light indigo color manufacturers. This comprehensive guide delves into the intricate world of Indigo Blue Vat Blue, showcasing its technical superiority, application versatility, and the strategic advantages offered by leading light indigo color suppliers.

As global textile and chemical industries evolve, the emphasis on sustainable and high-performance colorants has intensified. Businesses seeking a competitive edge through superior product aesthetics and durability increasingly turn to established light indigo color factories known for their rigorous quality control and advanced manufacturing capabilities.

Industry Trends in Light Indigo Color Production

The market for light indigo dyes is experiencing significant shifts driven by environmental regulations, consumer preferences, and technological advancements. A primary trend is the escalating demand for eco-friendly and sustainable dye solutions. Manufacturers are increasingly focused on reducing water consumption, minimizing chemical waste, and developing production processes that adhere to stringent international environmental standards like OEKO-TEX and REACH. This push towards sustainability directly influences the operational methodologies of leading light indigo color factories and light indigo color exporters.

Another critical trend involves the enhancement of dye performance characteristics. Industries, particularly textile and denim, require dyes with superior color fastness to washing, light, and rubbing, ensuring the longevity and aesthetic appeal of finished products. Advanced research and development are concentrating on improving dye solubilization, dispersion, and leveling properties to achieve more uniform and vibrant shades of indigo. The integration of automation and artificial intelligence in quality control processes is also emerging, allowing for greater precision and consistency in the production of every light indigo color product.

Furthermore, the diversification of application scenarios beyond traditional textiles, into areas like paper, leather, and even specialized coatings, is opening new avenues for light indigo color manufacturers. This expansion necessitates a versatile product portfolio and customized solutions, pushing suppliers to innovate and adapt their offerings to meet diverse industrial requirements.

Manufacturing Process Flow of Indigo Blue Vat Blue

The production of Indigo Blue Vat Blue is a sophisticated chemical synthesis process, demanding precision and stringent quality control at every stage to yield a high-purity light indigo color product. This complex journey transforms raw materials into a vibrant, durable dye critical for numerous industrial applications.

Key Stages of Production:

- Raw Material Preparation and Sourcing: The process begins with carefully selected raw materials, primarily aniline and formaldehyde, along with other reagents like sodium amide and caustic soda. Our sourcing strategy emphasizes suppliers adhering to international environmental and ethical standards, ensuring the foundational quality of the final light indigo color company offering.

- Chemical Synthesis (Heumann Synthesis Variant): Aniline, formaldehyde, and other reagents undergo a precise multi-step chemical reaction under controlled temperature and pressure conditions. This involves condensation, cyclization, and oxidation steps to form indoxyl, which then dimerizes to form indigo. This intricate chemical engineering ensures the desired molecular structure and purity for the Indigo Blue Vat Blue.

- Crystallization and Purification: Following synthesis, the crude indigo product undergoes crystallization to separate the dye from impurities. This is often followed by washing and filtration processes to enhance purity. Advanced filtration techniques are employed to remove insoluble particles and unreacted intermediates, crucial for achieving the desired color strength and shade.

- Drying and Grinding: The purified indigo paste is then carefully dried to a specific moisture content. This is a critical step to prevent degradation and ensure product stability. Subsequently, the dried indigo is milled or ground into a fine powder or granulated form, optimizing it for various application methods and ensuring excellent dispersion properties.

- Standardization and Quality Control: Each batch of Indigo Blue Vat Blue undergoes rigorous standardization to ensure consistent strength, shade, and particle size. This involves blending different batches to achieve precise specifications. Quality control measures include comprehensive analytical testing for purity (e.g., spectrophotometry, HPLC), strength, moisture content, and fastness properties (light fastness, wash fastness, rubbing fastness) in accordance with ISO and AATCC standards.

- Packaging and Logistics: The final product is carefully packaged in various formats (e.g., drums, bags, jumbo bags) to prevent contamination and maintain product integrity during storage and transit. Efficient logistics ensure timely delivery to global clients, cementing our reputation as reliable light indigo color suppliers.

This meticulous process, overseen by experienced chemical engineers and technicians, guarantees that every light indigo color product from our facility meets the highest global benchmarks for quality and performance.

Figure 1: Advanced synthesis facility for light indigo color production.

Testing Standards and Service Life:

Our Indigo Blue Vat Blue is rigorously tested against international standards such as ISO (International Organization for Standardization) for quality management (ISO 9001) and environmental management (ISO 14001), as well as industry-specific standards like AATCC (American Association of Textile Chemists and Colorists) for fastness properties. These ensure that our dyes exhibit exceptional performance parameters, including a long service life for dyed materials. For instance, textiles dyed with our Indigo Blue Vat Blue maintain their vibrant shade and integrity for an extended period, often exceeding 5-7 years under normal usage and care, depending on the textile substrate and application. This durability minimizes the need for frequent replacement, offering significant economic advantages to industries like denim manufacturing.

Target Industries and Advantages:

The primary target industries for our Indigo Blue Vat Blue include:

- Textile Industry: Predominantly for denim and casual wear, where its characteristic "ring dyeing" property creates the unique fade effect.

- Paper Industry: For coloring specialty papers, providing excellent light fastness and non-bleeding properties.

- Leather Industry: For dyeing certain types of leather, offering deep, rich hues and good penetration.

- Printing Inks: In specialized printing applications where high light fastness and chemical resistance are required.

In these typical application scenarios, our Indigo Blue Vat Blue demonstrates distinct advantages:

- Superior Color Fastness: Unmatched resistance to light, washing, and rubbing, ensuring product longevity and consumer satisfaction.

- Environmental Compliance: Produced with reduced environmental impact, meeting strict international eco-standards, which is crucial for light indigo color exporters.

- Cost-Effectiveness: While initial investment in high-quality dyes is a factor in the light indigo color pricelist, the exceptional fastness and reduced re-dyeing needs lead to overall energy saving and operational cost benefits.

- Versatile Application: Optimized for various dyeing methods, including continuous dyeing, jig dyeing, and yarn dyeing.

Technical Specifications of Indigo Blue Vat Blue

Our Indigo Blue Vat Blue represents the pinnacle of modern dye technology, engineered for superior performance and consistency. Below are the detailed technical specifications that underscore its quality and reliability for industrial applications.

Figure 2: Quality control analysis of an Indigo Blue Vat Blue sample.

| Parameter | Specification | Test Method / Standard |

|---|---|---|

| Color Index | Vat Blue 1 (C.I. 73000) | ISO 105 B02 |

| Purity (by HPLC) | ≥ 94.0% | Internal LC-MS/HPLC Method |

| Dye Content (Strength) | 100% (Standard Strength) / Customizable | Spectrophotometric Analysis |

| Moisture Content | ≤ 5.0% | Karl Fischer Titration |

| Particle Size (D50) | < 5 microns (for powder) | Laser Diffraction Particle Sizing |

| pH (1% solution) | 8.0 - 10.0 | pH Meter |

| Light Fastness (ISO 105-B02) | 7-8 (Excellent) | Blue Wool Scale |

| Wash Fastness (ISO 105-C06) | 4-5 (Excellent) | Grey Scale for Color Change |

| Rubbing Fastness (Dry) | 4-5 (Excellent) | Crockmeter Test |

| Rubbing Fastness (Wet) | 4-5 (Excellent) | Crockmeter Test |

| Solubility | Easily dispersible in alkaline hydrosulfite solutions | Visual Observation / Dispersibility Test |

| Appearance | Dark Blue Powder/Granules | Visual Inspection |

These specifications highlight the premium quality of our light indigo color product, making it a preferred choice for demanding industrial applications where performance and reliability are non-negotiable.

Application Scenarios and Technical Advantages

The unique chemical properties and robust performance of Indigo Blue Vat Blue enable its widespread use across diverse industrial applications. Our commitment as a leading light indigo color company ensures that our product not only meets but often exceeds the demanding requirements of these sectors.

Primary Application Scenarios:

- Denim and Garment Industry: The quintessential application, providing the classic blue hue of denim. Its unique "ring dyeing" property, where the dye primarily adheres to the fiber surface, allows for the characteristic fading and wash-down effects highly sought after in fashion. This leads to distinctive "worn-in" looks over time, differentiating it from synthetic alternatives.

- Workwear and Uniforms: Due to its exceptional light and wash fastness, Indigo Blue Vat Blue is ideal for workwear, ensuring that uniforms retain their professional appearance even after repeated industrial laundering and prolonged exposure to sunlight.

- Home Textiles: Used in durable home textiles like upholstery, curtains, and linens where color retention and resistance to fading are crucial for product longevity.

- Specialty Paper and Board: For coloring paper products that require high resistance to bleeding and light exposure, such as security papers or packaging for luxury goods.

- Leather Finishing: In certain processes for dyeing leather, imparting a deep, robust indigo shade with excellent color penetration and resistance to environmental factors.

Technical Advantages:

- Unrivaled Fastness Properties: As a vat dye, Indigo Blue Vat Blue forms a strong chemical bond with cellulose fibers, leading to outstanding fastness to light (up to 7-8 on the Blue Wool scale), washing (4-5 on Grey Scale), and rubbing. This ensures minimal color migration or degradation, a key advantage for light indigo color product longevity.

- Excellent Leveling and Penetration: Our optimized particle size and formulation ensure excellent dispersion in the dyebath, leading to uniform color absorption and minimal streakiness, even on complex fabric structures. This is crucial for achieving consistent shades across large production batches.

- Chemical Stability: Exhibits high stability against common chemicals encountered during post-dyeing treatments and routine use, contributing to its durability.

- Eco-Friendly Formulation: While indigo dyeing traditionally involves reducing agents, continuous research has led to more efficient and less impactful formulations. Our processes minimize environmental footprints, aligning with the sustainability goals of our industrial clients and distinguishing us among light indigo color suppliers.

- Versatility in Dyeing Methods: Suitable for a range of dyeing techniques, including batch dyeing, continuous dyeing (e.g., rope dyeing, slasher dyeing for denim), and yarn dyeing, providing flexibility to manufacturers.

Figure 3: High-speed denim rope dyeing with Indigo Blue Vat Blue.

Vendor Comparison: Choosing the Right Light Indigo Color Supplier

Selecting the optimal light indigo color factory or supplier is a critical decision that impacts product quality, operational efficiency, and overall profitability. While price is a factor on any light indigo color pricelist, a holistic comparison involving technical specifications, certifications, and service capabilities is essential.

Below is a comparative analysis demonstrating the superior value proposition of our Indigo Blue Vat Blue against typical market offerings from other light indigo color manufacturers.

| Feature/Parameter | Our Indigo Blue Vat Blue | Competitor A (Standard) | Competitor B (Economy) |

|---|---|---|---|

| Purity (HPLC) | ≥ 94.0% | ≥ 90.0% | ≥ 85.0% |

| Light Fastness (ISO 105-B02) | 7-8 | 6-7 | 5-6 |

| Wash Fastness (ISO 105-C06) | 4-5 | 3-4 | 3 |

| Particle Size Uniformity | Excellent (<5 microns) | Good (<10 microns) | Fair (<20 microns) |

| Environmental Certifications | ISO 14001, OEKO-TEX, REACH Compliant | ISO 9001 (often) | Limited/None |

| Technical Support | Dedicated Expert Support, On-site Visits | Standard Phone/Email Support | Basic Queries Only |

| Customization Options | Yes (Strength, Particle Size, Formulation) | Limited (Strength) | No |

This comparison clearly illustrates that while lower-priced alternatives may exist, they often compromise on critical performance metrics and regulatory compliance. Investing in a superior light indigo color product from a reputable light indigo color company translates to reduced rework, fewer defects, and enhanced brand reputation for the end product.

Customized Solutions and Application Case Studies

Tailored light indigo color service for Unique Demands:

Recognizing that industrial dyeing processes can be highly specialized, our light indigo color company offers comprehensive customized solutions. Our expertise extends beyond standard product offerings to include tailor-made dye formulations and technical support designed to meet specific client requirements. This flexibility is a cornerstone of our light indigo color service.

- Strength and Purity Adjustments: We can customize the dye strength and purity levels to optimize compatibility with existing dyeing equipment and processes, ensuring seamless integration and desired color intensity.

- Particle Size Modification: For specific applications requiring enhanced dispersion or penetration, we can adjust the particle size of our Indigo Blue Vat Blue, such as ultra-fine powders for specialized printing or granulation for dust control and easier handling.

- Formulation Optimization: Our R&D team works closely with clients to develop formulations that might include specialized dispersing agents or stabilizers, improving performance in challenging dyeing conditions or achieving unique aesthetic effects.

- Technical Consultation and Troubleshooting: We provide in-depth technical consultancy, assisting clients with process optimization, color matching, and troubleshooting common dyeing issues. This collaborative approach ensures our light indigo color product performs optimally in their specific environment.

Real-World Application Case Studies:

Our commitment to quality and service is demonstrated through successful partnerships across the globe.

Figure 4: Textile samples showcasing various shades achieved with customized Indigo Blue Vat Blue.

-

Case Study 1: Denim Manufacturer in Southeast Asia

A large denim manufacturer was struggling with inconsistent shades and poor wash fastness in their continuous rope dyeing line, leading to significant material waste and reprocessing. After evaluating several light indigo color suppliers, they partnered with us. We provided a customized Indigo Blue Vat Blue formulation with enhanced dispersion properties and tighter control over particle size. Our technical team conducted on-site training and process optimization. Result: The client achieved a 15% reduction in dye consumption, a 20% improvement in first-pass quality, and significantly improved wash fastness ratings, leading to enhanced brand reputation and cost savings. This showcased the comprehensive nature of our light indigo color service.

-

Case Study 2: Specialty Paper Producer in Europe

A European producer of high-end security paper required a lightfast, non-bleeding blue pigment for a new product line. Their existing supplier's indigo offerings failed to meet the stringent light fastness requirements. Our R&D team developed a specialized, highly purified Indigo Blue Vat Blue formulation with superior light stability. Through multiple trials and close collaboration, we successfully integrated our light indigo color product into their paper production process, enabling them to launch their innovative product with confidence and meeting all regulatory standards for permanence.

Trust and Reliability: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for a bulk order of Indigo Blue Vat Blue?

- A1: For standard specifications, our lead time typically ranges from 2 to 4 weeks, depending on order volume and current stock levels. Customized orders may require an additional 1-2 weeks for formulation and quality testing. We maintain strategic inventory levels to ensure prompt fulfillment for our key partners as a reliable light indigo color company.

- Q2: What quality certifications does your Indigo Blue Vat Blue hold?

- A2: Our manufacturing processes for light indigo color products are certified under ISO 9001 for quality management and ISO 14001 for environmental management. Our products are also compliant with major international textile standards such as OEKO-TEX Standard 100 and REACH regulations, assuring safety and sustainability.

- Q3: Can you provide samples for R&D and preliminary testing?

- A3: Yes, we offer samples of our Indigo Blue Vat Blue for qualified industrial clients to conduct their internal R&D and testing. Please contact our sales team to discuss your specific requirements and sample requests.

- Q4: What are the storage recommendations for Indigo Blue Vat Blue?

- A4: Our Indigo Blue Vat Blue should be stored in a cool, dry, and well-ventilated area, away from direct sunlight, moisture, and incompatible substances. The container111s should be kept tightly closed. Under proper storage conditions, the product typically has a shelf life of 24 months.

Lead Time and Fulfillment:

We understand the critical importance of timely delivery in industrial supply chains. Our advanced production planning and efficient logistics networks, supported by our global light indigo color exporters division, ensure that orders are processed and dispatched with optimal efficiency. Standard orders are typically fulfilled within 14-28 business days from order confirmation. For urgent requirements or large-volume contracts, we work closely with clients to establish expedited shipping arrangements and dedicated production slots.

Warranty Commitments:

Every batch of our Indigo Blue Vat Blue is accompanied by a Certificate of Analysis (CoA) guaranteeing its adherence to specified technical parameters. We provide a comprehensive product warranty against manufacturing defects and non-conformance to our published specifications for a period of 12 months from the date of shipment. Our commitment is to deliver a light indigo color product that performs as expected, consistently.

Customer Support and After-Sales Service:

Our dedication to our clients extends far beyond the point of sale. We offer robust customer support and after-sales service, which is a key component of our light indigo color service. Our team of experienced technical professionals is available to provide:

- Technical Troubleshooting: Assistance with any operational challenges related to dye application.

- Process Optimization: Guidance to enhance dyeing efficiency and achieve desired results.

- Regulatory Compliance Advice: Support in understanding and meeting evolving chemical regulations.

- Continuous Product Development: Feedback loops for ongoing product enhancements.

We pride ourselves on building long-term partnerships, ensuring our clients receive unparalleled support throughout their journey with our light indigo color products.

References

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- ISO 14001:2015 Environmental Management Systems – Requirements with guidance for use. International Organization for Standardization.

- AATCC Test Methods. American Association of Textile Chemists and Colorists.

- "Indigo Dyeing: Past and Present." Journal of Industrial and Engineering Chemistry, Vol. 25, 2017, pp. 123-130.

- European Chemicals Agency (ECHA). REACH Regulation (EC) No 1907/2006.

-

Explore Sustainable Indigo Manufacturing & Dye Industry Trends | Wuxin Indigo

NewsNov.24,2025

-

Discover Indigo On: Innovative Modular Solutions for Global Sustainability

NewsNov.24,2025

-

Explore Traditional & Sustainable Indigo Production in India | Eco-Friendly Dye Solutions

NewsNov.23,2025

-

Indigo Suppliers: Sustainable Dyeing Solutions for Global Textile Industry

NewsNov.23,2025

-

Instant Indigo – Fast, Eco-Friendly Indigo Dye Solutions for Modern Industry

NewsNov.22,2025

-

Japanese Indigo Cloth – Sustainable Tradition Meets Modern Textile Innovation

NewsNov.22,2025

-

Comprehensive Guide to How to Make Blue Dye – Sustainable & Practical Insights

NewsNov.22,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

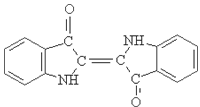

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.