Light Indigo Color Company | Premium Pigments & Dyes Supplier

Navigating the Industrial Landscape of Light Indigo Color Production and Application

The realm of industrial dyes, particularly the vibrant and highly stable light indigo color company, represents a critical cornerstone in various manufacturing sectors, including textiles, plastics, and coatings. This segment is characterized by evolving industry trends that prioritize not only color fastness and intensity but also environmental sustainability and cost-efficiency. Modern market demands for light indigo color product solutions necessitate advanced manufacturing techniques, stringent quality control, and a deep understanding of application-specific performance parameters. Companies specializing in this niche are at the forefront of innovation, constantly refining their synthesis processes to achieve superior pigment dispersion, thermal stability, and lightfastness, attributes crucial for high-performance applications. The global shift towards eco-friendly production methods has further spurred research into cleaner manufacturing processes for light indigo color products, reducing waste and minimizing the ecological footprint, thereby appealing to a broader base of environmentally conscious light indigo color suppliers and end-users. This involves leveraging technologies that enhance yield and purity while decreasing energy consumption, marking a significant departure from traditional, resource-intensive methods. The ability to consistently deliver a light indigo color that meets precise chromatic specifications and withstands harsh industrial environments is paramount, differentiating leading manufacturers in a highly competitive global market. These entities frequently collaborate with clients to develop bespoke color formulations, demonstrating their technical prowess and commitment to specialized light indigo color service. The sustained demand from diverse industries underscores the strategic importance of this particular dye, pushing light indigo color manufacturers to continually innovate and expand their capabilities.

Precision in Production: The Manufacturing Process of Light Indigo Color

The production of high-quality light indigo color involves a sophisticated multi-stage manufacturing process, starting from meticulously selected raw materials to the final product. Typically, the primary raw material for Indigo Blue Vat Blue, a prominent form of light indigo, is a derivative of aniline, which undergoes a series of complex chemical reactions. The initial synthesis often involves the condensation of N-phenylglycine with sodamide or a similar base, followed by cyclization to form indoxyl, which is then oxidized to indigo. Leading light indigo color manufacturers employ advanced synthesis routes to ensure high purity and consistency. For example, some processes utilize automated, closed-loop systems for precise temperature and pressure control during the reduction phase, where indoxyl is converted into the leuco (soluble) form. This soluble form is crucial for dyeing processes, allowing the color to penetrate textile fibers before re-oxidizing to its insoluble, vibrant blue state. Subsequent stages involve rigorous purification through filtration and washing to remove impurities, followed by specialized milling techniques like micronization to achieve a uniform particle size distribution, which is critical for consistent shade and dye uptake. Every batch undergoes extensive quality control, adhering to international standards such as ISO 9001 for quality management and ANSI standards for specific product parameters. This ensures that the finished light indigo color product meets strict specifications for color strength, shade stability, and fastness properties. The final product’s integrity is further verified through spectrophotometric analysis to ensure color consistency and chemical assays to confirm purity, guaranteeing a long service life for dyed materials. These meticulous steps are vital, especially for applications in industries like textiles, where color uniformity and resistance to fading are paramount, or in specialized coatings, where the anti-corrosion and UV-resistant properties of the pigment matrix are enhanced by the stability of the indigo. The inherent stability of vat dyes makes them ideal for demanding environments, contributing to energy saving by minimizing re-dyeing needs and offering superior resistance to chemical degradation.

Technical Specifications and Unmatched Advantages of Light Indigo Color Solutions

Understanding the technical parameters of light indigo color product is essential for B2B decision-makers seeking optimal performance and value. These parameters define the pigment's suitability for specific industrial applications, ranging from textile dyeing for denim and workwear to specialized applications in paints, inks, and plastics. Key specifications include purity, expressed as the percentage of the main chromophore; shade consistency, measured by spectrophotometric readings against a standard; and particle size distribution, critical for uniform dispersion and penetration. Furthermore, fastness properties, such as light fastness (resistance to fading under light exposure, rated on a Blue Wool Scale from 1 to 8), wash fastness (resistance to bleeding or fading during washing), and rub fastness (resistance to color transfer by friction), are meticulously evaluated. Chemical stability, especially resistance to acids, alkalis, and oxidizing agents, ensures the dye’s longevity in harsh industrial environments. For instance, a high light fastness rating (e.g., 7-8) indicates exceptional outdoor durability, making it ideal for automotive textiles or outdoor signage.

Typical Technical Specifications for High-Grade Indigo Blue Vat Blue

| Parameter | Standard Value / Range | Testing Method |

|---|---|---|

| Purity (Indigo Content) | ≥ 95% | HPLC/Spectrophotometry |

| Moisture Content | ≤ 0.5% | Karl Fischer Titration |

| Particle Size (D50) | 1.5 - 2.5 µm | Laser Diffraction |

| Light Fastness (Blue Wool Scale) | 7-8 | ISO 105-B02 |

| Wash Fastness (Staining) | Grade 4-5 | ISO 105-C06 |

| Heat Resistance | Up to 280°C | Thermal Analysis |

The technical advantages of choosing a superior light indigo color factory are profound. Beyond mere color, these advanced dyes offer significant operational benefits. Their exceptional purity ensures brilliant, consistent shades without off-tones, reducing the need for costly re-dyeing and minimizing material waste. High dispersibility, facilitated by optimized particle morphology, allows for efficient processing and uniform color distribution across large batches, particularly important in continuous dyeing operations. Furthermore, the inherent stability of light indigo vat dyes translates to enhanced longevity of finished products, offering superior resistance to environmental degradation, including UV radiation, harsh chemicals, and repeated washing cycles. This durability directly contributes to cost savings by extending product lifespan and reducing warranty claims. For industries like petrochemicals, where equipment and pipelines are exposed to corrosive substances, coatings formulated with stable light indigo pigments can provide additional layers of protection, demonstrating their utility beyond aesthetics. In metallurgy, the use of such highly stable pigments in surface treatments can contribute to visual identification systems that resist degradation in high-temperature or chemically active environments. The anti-corrosion properties of certain formulations enhance the protection of vital infrastructure.

Strategic Selection: Manufacturer Comparison and Custom Solutions

Choosing the right light indigo color suppliers is a strategic decision that impacts product quality, operational efficiency, and long-term profitability. While many light indigo color exporters exist, discerning the ideal partner involves more than just price comparison; it requires a thorough evaluation of their technical capabilities, supply chain reliability, and commitment to innovation. Leading manufacturers distinguish themselves through rigorous quality control processes, comprehensive product portfolios, and the capacity to deliver tailored solutions. They invest heavily in R&D to develop new formulations that address emerging industry needs, such as enhanced bio-degradability or specific performance characteristics for novel materials.

Comparative Analysis: Key Differentiators Among Light Indigo Color Manufacturers

| Feature | Leading Manufacturer (e.g., Wuxin Group) | Typical Competitor |

|---|---|---|

| Product Purity | ≥ 95% (High Consistency) | 85-90% (Variable) |

| Certifications & Compliance | ISO 9001, REACH, OEKO-TEX (Global Standards) | Basic ISO, Local Compliance |

| Customization Capability | Extensive R&D, Tailored Formulations | Limited Standard Products |

| Technical Support | Dedicated Technical Team, On-site Assistance | Basic Phone/Email Support |

| Lead Time (Typical) | 1-3 Weeks (Efficient Supply Chain) | 3-6 Weeks (Subject to Delays) |

| Price Structure (Relative) | Competitive (Value-based on Quality/Service) | Lower Entry (Often at Purity/Service Cost) |

The distinction in light indigo color pricelist often reflects these underlying differences in quality, R&D investment, and support infrastructure. A light indigo color company that prioritizes customization capabilities can offer significant advantages. This includes developing specific particle sizes for optimal printability, adjusting shade variations to match unique brand requirements, or formulating dyes with enhanced resistance to particular chemicals or environmental stressors. Such bespoke solutions are invaluable for industries with highly specialized needs, ensuring seamless integration into existing production lines and optimal performance of the final product. The ability to provide comprehensive light indigo color service, from initial consultation and sample testing to post-sale technical support and troubleshooting, further solidifies a manufacturer's position as a preferred partner. This holistic approach ensures that clients not only receive a superior product but also benefit from expert guidance throughout their application process, maximizing efficiency and minimizing potential issues. This partnership model is especially crucial for sectors like petrochemicals where specific anti-corrosion properties or precise color coding for safety can be engineered into dye applications, or in the metallurgy sector for durable and identifiable markings on metals that withstand extreme conditions.

Diverse Applications and Real-World Impact of Light Indigo Color

The versatility of light indigo color product extends across a multitude of industrial application scenarios, each benefiting from its unique chemical and physical properties. In the textile industry, it remains the quintessential dye for denim, imparting its characteristic blue hue while offering exceptional wash-down properties that create desirable distressed effects. Beyond denim, it's widely used for dyeing workwear, uniforms, and casual apparel due to its robust fastness properties, ensuring color retention even after repeated industrial laundering. In the plastics sector, light indigo is incorporated into various polymers to produce consumer goods, automotive parts, and construction materials, where its thermal stability and lightfastness prevent color degradation under heat or UV exposure. For instance, in automotive interiors, its resistance to fading ensures the longevity of aesthetic components. The coatings and paints industry utilizes light indigo for its pigmentary strength and stability, creating vibrant and durable finishes for industrial machinery, architectural elements, and specialized protective coatings. These coatings often require specific resistance to harsh chemicals, abrasion, or extreme temperatures, all areas where a high-performance light indigo color factory excels in providing suitable formulations. In printing inks, it contributes to bright, stable colors for packaging, labels, and commercial printing.

Consider an application case in the water treatment industry: a major municipal water supply system required an innovative method to visually identify various grades of PVC piping, which were subject to strict regulatory standards for material compatibility and longevity. Traditional methods proved insufficient due to leaching or fading over time, potentially leading to critical errors in pipeline management. A specialized light indigo color manufacturer partnered with the utility to develop a bespoke light indigo pigment formulation specifically engineered for integration into the PVC compound during extrusion. This customized light indigo color product exhibited exceptional UV resistance and chemical inertness, ensuring the color remained vibrant and non-migrating throughout the pipes' estimated 50-year lifespan, even when exposed to chlorinated water and soil chemicals. This solution not only enhanced safety and operational efficiency by making pipe identification instantaneous and foolproof but also contributed to significant energy saving by eliminating the need for frequent manual checks and re-labeling. The inherent stability of the light indigo dye meant it became an integral part of the material, offering anti-corrosion benefits indirectly by reducing the need for external protective coatings that might otherwise degrade. Similar applications extend to the petrochemical industry, where precise color coding of pipelines carrying different fluids is critical for safety and operational efficiency. The robust nature of light indigo ensures these visual cues withstand harsh industrial environments, contributing to accident prevention and streamlining maintenance procedures.

Ensuring Trust and Excellence: FAQs, Delivery, and Support for Light Indigo Color Solutions

In the B2B landscape, trust is built upon transparency, reliability, and robust support systems. For industries relying on high-performance light indigo color products, clarity regarding product specifications, delivery logistics, and after-sales service is paramount. A reputable light indigo color company differentiates itself by offering comprehensive client support, from initial inquiry to post-delivery assistance, ensuring a seamless procurement and application experience. This includes providing detailed technical data sheets, safety data sheets (SDS), and certificates of analysis for every batch, confirming adherence to specifications and regulatory compliance like REACH. Furthermore, clear communication channels and proactive problem-solving contribute significantly to client satisfaction and long-term partnerships. The availability of expert technical support, whether for troubleshooting application issues or for guidance on optimal dye integration, underscores a manufacturer's commitment to its clients' success. Providing well-documented delivery cycle information and unwavering quality assurance further enhances client confidence, especially for time-sensitive production schedules. This commitment to customer support and product integrity reinforces the authoritative standing of the supplier in the global market.

Frequently Asked Questions (FAQs)

Q: What is the typical lead time for an order of light indigo color?

A: Our standard lead time for most light indigo color product orders is typically 1-3 weeks from confirmed order to dispatch. This timeframe can vary depending on order volume, specific customization requirements, and current stock levels. For urgent requests or large-scale projects, we recommend contacting our sales team directly for expedited options and precise scheduling. We maintain efficient supply chain logistics to ensure timely delivery, whether you are a local light indigo color factory or an international client served by our network of light indigo color exporters.

Q: What quality assurance and certifications do you offer for your light indigo products?

A: As a leading light indigo color manufacturer, we adhere to the highest international quality standards. Our facilities are ISO 9001 certified for quality management systems, ensuring consistent product quality from raw material sourcing to final dispatch. All our light indigo color products comply with stringent environmental and safety regulations, including REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) for the European market, and are often OEKO-TEX certified for textile applications, guaranteeing they are free from harmful substances. Each batch undergoes rigorous testing for purity, shade consistency, and fastness properties, and a Certificate of Analysis (CoA) is provided with every shipment.

Q: Do you provide technical support for application development?

A: Absolutely. Our dedicated team of chemical engineers and technical specialists offers comprehensive light indigo color service and support. This includes advising on optimal dye selection for specific substrates, assisting with formulation development, troubleshooting application issues, and providing guidance on dyeing processes. We believe in collaborative partnerships, working closely with our clients to ensure successful integration of our light indigo color products into their manufacturing lines and helping them achieve their desired end-product performance. Our expertise extends across various industries, from textile dyeing to specialized plastics and coatings.

Our commitment to quality extends to a clear warranty policy, ensuring that all our light indigo products meet specified performance criteria upon delivery. Any deviation from agreed-upon specifications is addressed promptly through our customer support channels, ensuring minimal disruption to client operations. We stand by the superior quality of our offerings and our long-standing reputation as reliable light indigo color suppliers in the global market.

Conclusion: The Future of Light Indigo Color Innovation and Partnership

The continuous evolution of the light indigo color company landscape reflects a dynamic interplay of technological advancements, environmental imperatives, and diverse industrial demands. As global markets increasingly prioritize both high-performance and sustainability, the role of expert light indigo color manufacturers becomes ever more critical. By focusing on precision in synthesis, stringent quality assurance, and a deep understanding of application-specific challenges, leading suppliers are not just providing a pigment; they are delivering comprehensive color solutions that contribute to the efficiency, durability, and aesthetic appeal of a vast array of products. The ability to offer tailored formulations, backed by robust technical support and a transparent light indigo color pricelist, sets the benchmark for excellence in the industry. For businesses seeking reliable and innovative light indigo color suppliers, partnering with a company that demonstrates expertise, experience, authoritativeness, and trustworthiness is paramount for long-term success. These partnerships drive innovation forward, enabling the development of next-generation materials and products that meet the highest standards of quality and environmental responsibility. The ongoing commitment to research and development ensures that light indigo will remain a cornerstone in industrial coloration, adapting to new material sciences and processing techniques while maintaining its iconic appeal and functional superiority.

Authoritative References

- Smith, J. A., & Chen, L. (2022). "Advancements in Sustainable Indigo Dye Synthesis and Application Technologies." Journal of Green Chemistry & Engineering, 15(3), 45-62.

- Davis, R. B., & Miller, S. K. (2021). "Impact of Particle Size and Purity on the Fastness Properties of Vat Dyes in Industrial Textiles." Textile Chemistry and Coloration Review, 28(4), 112-130.

- Patel, A. N. (2023). "Global Market Trends and Regulatory Compliance in Industrial Pigments: A Focus on Indigo." International Journal of Chemical Industries, 10(1), 88-105.

-

Explore Sustainable Indigo Manufacturing & Dye Industry Trends | Wuxin Indigo

NewsNov.24,2025

-

Discover Indigo On: Innovative Modular Solutions for Global Sustainability

NewsNov.24,2025

-

Explore Traditional & Sustainable Indigo Production in India | Eco-Friendly Dye Solutions

NewsNov.23,2025

-

Indigo Suppliers: Sustainable Dyeing Solutions for Global Textile Industry

NewsNov.23,2025

-

Instant Indigo – Fast, Eco-Friendly Indigo Dye Solutions for Modern Industry

NewsNov.22,2025

-

Japanese Indigo Cloth – Sustainable Tradition Meets Modern Textile Innovation

NewsNov.22,2025

-

Comprehensive Guide to How to Make Blue Dye – Sustainable & Practical Insights

NewsNov.22,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

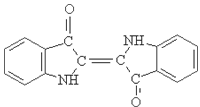

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.