Light Indigo Color Company: Premium Pigments & Dyes

The Indispensable Role of a light indigo color company in Modern Industries

In the intricate tapestry of industrial chemistry, the role of a proficient light indigo color company is paramount. Specializing in high-purity chemical dyes, particularly Indigo Blue Vat Blue, these entities are foundational to numerous sectors, from textiles to advanced materials. This article delves into the comprehensive capabilities, technical specifications, and strategic advantages offered by leading suppliers in this niche, providing a B2B perspective essential for procurement and R&D professionals.

The demand for consistent quality and technical precision in indigo color production necessitates a deep understanding of chemical synthesis and application. As key players, light indigo color company entities drive innovation, ensuring product integrity and performance across diverse industrial applications, thereby setting benchmarks for quality among light indigo color manufacturers globally.

Manufacturing Process: From Precursor to Pigment Excellence

The production of Indigo Blue Vat Blue by a leading light indigo color company is a sophisticated, multi-stage chemical synthesis process, demanding stringent quality control at every phase. The primary method involves the reductive cyclization of N-phenylglycine derivatives, typically via the Heumann or Baeyer-Drewson synthesis pathways.

Key Process Steps:

- Raw Material Preparation: High-purity aniline and chloroacetic acid are key precursors. Aniline reacts with chloroacetic acid to form N-phenylglycine, a crucial intermediate. The selection of these materials is critical, often sourced from ISO-certified suppliers to ensure baseline purity.

- Fusion (Indigo Melt): N-phenylglycine undergoes fusion with a strong base (e.g., sodium hydroxide, sodium amide) and often potassium ferricyanide as an oxidizing agent, typically at high temperatures (around 200-250°C). This melt process leads to the formation of indoxyl, which is highly reactive.

- Oxidation & Precipitation: The indoxyl melt is then cooled and oxidized, usually by air, in an aqueous alkaline solution. This step induces the dimerization of indoxyl to form insoluble indigo (Indigo Blue Vat Blue) pigment, which precipitates out. Careful control of pH and oxygen supply is vital to maximize yield and purity, avoiding side reactions.

- Purification & Filtration: The crude indigo pigment is subjected to rigorous washing to remove impurities, unreacted reagents, and inorganic salts. This is often followed by hot filtration and several washes with demineralized water.

- Grinding & Standardization: The purified indigo cake is then dried and finely ground to achieve the desired particle size distribution, which directly impacts dyeing performance and color fastness. Modern light indigo color factories utilize advanced milling techniques to ensure uniform particle size. Batches are standardized for shade and strength to meet specific customer requirements, often requiring blending.

- Quality Assurance & Packaging: Each batch undergoes comprehensive testing against international standards. Products are packaged in multi-ply bags or drums, designed for moisture protection and easy handling for a typical light indigo color product.

Stringent testing standards, including ISO 9001 for quality management and ISO 14001 for environmental management, are adhered to by reputable light indigo color manufacturers. Product specifications often align with international textile industry standards, such as those for color fastness and heavy metal content.

Figure 1: Simplified Flowchart of Indigo Synthesis.

The service life of Indigo Blue Vat Blue, when stored correctly, typically extends to 2-3 years without significant degradation in performance. Target industries include textiles (denim, workwear), printing inks, and specialized coating applications, where its unique color and fastness properties are highly valued.

Industry Trends and Market Dynamics for Light Indigo Color

The global market for indigo dyes is influenced by several evolving trends. Sustainable manufacturing practices are at the forefront, with increasing pressure on light indigo color company operations to adopt eco-friendly synthesis routes, reduce water consumption, and manage waste effectively. The shift towards bio-indigo production, though still nascent, represents a significant future direction, driven by consumer demand for natural and sustainable products.

Digitalization in textile dyeing processes is also impacting demand, pushing for more consistent and standardized dye products. Furthermore, the diversification of indigo applications beyond denim, into high-performance textiles and other industrial pigments, is creating new growth opportunities for agile light indigo color exporters. Geopolitical factors and raw material price fluctuations continue to pose challenges, requiring robust supply chain management from all light indigo color suppliers.

Technical Specifications of Indigo Blue Vat Blue

Understanding the precise technical parameters is critical for optimal application and performance. A reputable light indigo color company provides detailed specifications, ensuring compatibility and efficiency in industrial processes. The following table outlines typical specifications for high-grade Indigo Blue Vat Blue powder, commonly supplied by leading light indigo color manufacturers.

Figure 2: High-purity Indigo Blue Vat Blue powder.

| Parameter | Specification | Test Method / Standard |

|---|---|---|

| C.I. Name | Vat Blue 1 | Color Index International |

| CAS No. | 482-89-3 | Chemical Abstracts Service |

| Strength | 100% min (Standardized) | Spectrophotometry (e.g., DIN 54000) |

| Appearance | Dark Blue Powder / Granules | Visual Inspection |

| Purity (Indigo Content) | ≥ 94% | HPLC |

| Moisture Content | ≤ 0.5% | Karl Fischer Titration |

| Particle Size | > 95% | Laser Diffraction |

| pH (1% aqueous solution) | 6.0 - 8.0 | pH Meter |

| Light Fastness (Cotton) | 7-8 (Excellent) | ISO 105-B02 |

| Washing Fastness (Cotton) | 5 (Excellent) | ISO 105-C06 (A2S) |

| Heavy Metals | Below Detection Limits (Pb | ICP-MS / OEKO-TEX® Standard 100 |

These parameters underscore the high quality and performance expected from a premium light indigo color product. Compliance with ISO and other relevant industry standards provides assurance of product consistency and safety.

Application Scenarios and Technical Advantages

The versatility of Indigo Blue Vat Blue, supplied by a leading light indigo color company, extends across multiple industrial sectors due to its distinctive properties.

Primary Application Scenarios:

- Textile Industry (Denim Dyeing): The most prominent application, providing the iconic blue hue for denim. Its vat dyeing process allows for ring dyeing, where the dye penetrates only the surface of the cotton fiber, resulting in the characteristic fade and wash-down effects.

- Workwear and Uniforms: Due to its exceptional fastness properties against light, washing, and abrasion, indigo is ideal for workwear, ensuring durability and color retention in demanding environments.

- Pigments and Inks: Used as a pigment in specialized inks for printing and for artistic applications, where its deep blue color is desired.

- Specialty Coatings: In niche applications, indigo can be incorporated into coatings for its color and UV resistance.

Technical Advantages:

- Exceptional Fastness: Superior light fastness, wash fastness, and rub fastness compared to many other dyes, ensuring longevity and minimal color bleeding. This is a critical advantage for the demanding textile industry.

- Unique Fading Characteristics: The distinctive way indigo fades over time, giving denim its desired worn look, is unmatched by synthetic alternatives.

- Versatility in Shades: While known for its deep blue, the depth of color can be controlled by the number of dye dips and concentration, allowing for a wide range of blue shades.

- Eco-friendly Potential: While traditional synthesis has environmental challenges, advancements in production by a responsible light indigo color factory are leading to greener processes, including enzymatic reduction and bio-indigo.

- Chemical Stability: As a vat dye, indigo is applied in its soluble leuco form and then oxidized back to its insoluble pigment form, offering excellent resistance to various chemical agents post-application.

Figure 3: Chemical Structure of Indigo Blue (Indigotin).

These advantages solidify Indigo Blue Vat Blue's position as a premium choice for industries requiring robust and aesthetically pleasing coloring solutions.

Vendor Comparison: Selecting the Right Light Indigo Color Supplier

When selecting a light indigo color company, B2B buyers must evaluate not only the product's light indigo color pricelist but also a range of critical factors including quality consistency, production capacity, certifications, and after-sales support. Below is a comparative overview of typical considerations when evaluating light indigo color suppliers.

| Feature | Supplier A (Premium) | Supplier B (Mid-Range) | Supplier C (Value) |

|---|---|---|---|

| Product Purity | ≥ 94% | ≥ 92% | ≥ 90% |

| Certifications | ISO 9001, ISO 14001, OEKO-TEX® | ISO 9001 | None specified / Basic QC |

| Lead Time (Avg.) | 7-14 days | 14-21 days | 21-30+ days |

| Technical Support | Dedicated team, on-site visits | Email/phone support | Limited response |

| Customization | Particle size, shade matching, specialized formulations | Basic shade matching | Minimal |

| Sustainability Initiatives | Eco-friendly processes, waste reduction, R&D in bio-indigo | Basic compliance | Minimal focus |

| Price Point | Premium | Competitive | Economical |

Choosing a reliable light indigo color company involves balancing budget with long-term operational efficiency and adherence to quality benchmarks. Premier light indigo color exporters often provide comprehensive service beyond just product delivery.

Customized Solutions and Application Case Studies

A forward-thinking light indigo color company understands that one size does not fit all. They offer customized solutions to meet specific client requirements, optimizing performance and cost-efficiency. This customization can involve specific particle size distributions for different dyeing techniques, tailored shades for unique fabric blends, or specialized packaging for automated dispensing systems.

Customization Options:

- Particle Size Optimization: For specific dyeing methods (e.g., rope dyeing vs. slasher dyeing), fine-tuning particle size enhances penetration and reduces speckiness.

- Shade and Strength Adjustment: Developing custom formulations to match precise color standards for brand consistency.

- Dispersibility Enhancements: Offering pre-reduced indigo or high-dispersibility powders to simplify vat preparation and improve dyeing efficiency.

- Environmentally Compliant Products: Producing indigo dyes with ultra-low heavy metal content or specific eco-label certifications.

Figure 4: A modern production facility for light indigo color products.

Application Case Study: High-Volume Denim Production

A leading denim manufacturer faced challenges with inconsistent shade depth and excessive chemical consumption in their rope dyeing process. Partnering with a specialized light indigo color service provider, they implemented a customized Indigo Blue Vat Blue formulation featuring enhanced dispersibility and optimized particle size. This collaboration resulted in:

- 20% Reduction in Dyeing Time: Improved dispersibility allowed for faster vat preparation and more efficient dye uptake.

- 15% Decrease in Reductant Usage: The optimized formulation required less hydrosulfite, contributing to cost savings and environmental benefits.

- Achieved ±0.5 ΔE Color Consistency: Significantly improved shade uniformity across large production batches, reducing rework.

- Extended Bath Life: Greater stability of the dye bath led to less frequent disposal and replenishment.

This case study exemplifies how a targeted light indigo color product solution can lead to substantial operational improvements and environmental advantages.

Commitment to Trustworthiness and Customer Support

A reliable light indigo color company prioritizes customer trust through transparent operations, clear commitments, and robust support systems. Our dedication to Google principles ensures that every interaction and product delivery upholds the highest standards.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a large order of Indigo Blue Vat Blue?

- A: Standard lead time for bulk orders is generally 7-14 business days, depending on volume and current stock. For customized formulations, it may extend to 3-4 weeks to allow for production and rigorous quality testing. We maintain strategic inventory levels to support urgent requests from light indigo color factories.

- Q: What are your quality assurance standards and certifications?

- A: We operate under ISO 9001 certified quality management systems and ISO 14001 environmental management. Our products undergo rigorous testing according to international standards (e.g., ISO 105 series for fastness, OEKO-TEX® for ecological safety) before dispatch. This commitment is central to our reputation as a leading light indigo color company.

- Q: Do you provide technical support for application challenges?

- A: Yes, our experienced technical team offers comprehensive support, including process optimization, shade matching, troubleshooting, and on-site consultations for our clients. This light indigo color service extends to all aspects of dye application and performance.

- Q: What is the shelf life and recommended storage for your Indigo Blue Vat Blue products?

- A: When stored in original, sealed packaging in a cool, dry place away from direct sunlight and moisture, our Indigo Blue Vat Blue has a shelf life of 2-3 years. Proper storage is crucial to maintain product integrity and performance.

Warranty and After-Sales Support

We offer a standard product warranty covering material defects and adherence to specified technical parameters. In the unlikely event of any issue, our dedicated after-sales support team is readily available to provide timely assistance, including product replacement or credit, subject to our terms and conditions. We strive for complete customer satisfaction, solidifying our position among reputable light indigo color suppliers.

Conclusion

The intricate world of industrial dyes, particularly for Indigo Blue Vat Blue, relies heavily on the expertise, experience, and trustworthiness of a dedicated light indigo color company. From meticulous manufacturing processes to stringent quality control and comprehensive customer support, leading suppliers are instrumental in ensuring the performance and sustainability of countless products across global industries. Partnering with a highly reputable light indigo color company guarantees not just a chemical product, but a strategic asset integral to manufacturing excellence.

References

- Bredereck, K. & Schur, M. (1998). Indigo and its Derivatives. In: Ullmann's Encyclopedia of Industrial Chemistry. Wiley-VCH.

- Chen, H. L., & Cai, Z. (2018). Dyeing and Finishing of Textiles. Woodhead Publishing.

- European Chemicals Agency (ECHA). (n.d.). Indigotin (Indigo Blue). Retrieved from [Specific ECHA publication or database link, if available].

- International Organization for Standardization (ISO). (n.d.). ISO 105 series - Textiles - Tests for colour fastness.

- OEKO-TEX® Association. (n.d.). OEKO-TEX® Standard 100.

-

Explore Sustainable Indigo Manufacturing & Dye Industry Trends | Wuxin Indigo

NewsNov.24,2025

-

Discover Indigo On: Innovative Modular Solutions for Global Sustainability

NewsNov.24,2025

-

Explore Traditional & Sustainable Indigo Production in India | Eco-Friendly Dye Solutions

NewsNov.23,2025

-

Indigo Suppliers: Sustainable Dyeing Solutions for Global Textile Industry

NewsNov.23,2025

-

Instant Indigo – Fast, Eco-Friendly Indigo Dye Solutions for Modern Industry

NewsNov.22,2025

-

Japanese Indigo Cloth – Sustainable Tradition Meets Modern Textile Innovation

NewsNov.22,2025

-

Comprehensive Guide to How to Make Blue Dye – Sustainable & Practical Insights

NewsNov.22,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

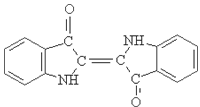

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.