Creating Factories for Producing High-Quality Blue Dye Efficiently and Sustainably

The Rise of Blue Dye Factories A Deep Dive into Sustainable Color Production

In recent years, the fashion and textile industries have faced mounting pressure to adopt sustainable practices, especially when it comes to dye production. Among a myriad of colors, blue dye has captured the interest of manufacturers and consumers alike due to its popularity and the challenges associated with its traditional production methods. This article explores the evolution of blue dye factories, focusing on innovative approaches that prioritize environmental sustainability.

Historical Context of Blue Dye

Blue dye has a rich history that dates back thousands of years. Ancient civilizations such as the Egyptians and the indigo-dyeing cultures in India created stunning blue textiles that were highly coveted. Historically, blue dyes were primarily derived from natural sources, notably indigo, a plant grown in tropical and subtropical regions. However, as the industrial revolution unfolded, synthetic dyes gained prominence, leading to the widespread use of chemical processes that often discharged hazardous waste into the environment.

The Environmental Impact of Traditional Practices

The shift to synthetic blue dyes, although efficient and cost-effective, has come at a significant ecological cost. Factories that rely on these processes have often contributed to water pollution, soil degradation, and health risks for workers. The production of synthetic dyes typically involves toxic chemicals, which, when improperly managed, can leach into waterways and disrupt local ecosystems. In recent years, communities surrounding dye factories have raised concerns about their health and environment due to the pollutants released during dyeing processes.

A New Era of Blue Dye Production

Recognizing these issues, a new era of blue dye production is emerging, one that focuses on sustainability and innovative practices. Modern blue dye factories are increasingly adopting eco-friendly techniques and materials. Natural dyeing processes are making a comeback, as artisans and manufacturers explore ways to harness plant-based dyes, including indigo and woad. This resurgence not only reduces reliance on toxic chemicals but also promotes biodiversity through the cultivation of traditional dye plants.

make blue dye factories

Moreover, advancements in biotechnology are leading to the creation of synthetic dyes derived from sustainable sources. For instance, some companies are now producing indigo through fermentation processes involving microorganisms. This method significantly reduces water usage and eliminates harmful by-products, positioning biotechnology as a powerful tool in the dyeing industry’s transformation.

The Role of Blue Dye Factories in the Circular Economy

Another pivotal aspect of modern blue dye factories is their integration into the circular economy. The concept of a circular economy emphasizes reducing waste, reusing materials, and recycling products. Many forward-thinking dye manufacturers are adopting these principles by implementing closed-loop systems that recycle water and chemicals used in the dyeing process. This not only minimizes environmental impact but also leads to cost savings and resource efficiency.

Additionally, brands are increasingly transparent about their sourcing and dyeing practices. Consumers are now more informed and discerning, seeking out products that adhere to ethical and sustainable production standards. This shift is driving demand for responsibly made blue textiles, encouraging factories to adopt cleaner, greener technologies.

The Future of Blue Dye Factories

The future of blue dye factories looks promising, as innovation and sustainability drive change within the industry. As technology continues to advance, manufacturers are likely to discover even more efficient and eco-friendly solutions for blue dye production. Collaborations among chemists, designers, and sustainability experts can produce novel hues while adhering to environmental standards.

Furthermore, education plays a crucial role in fostering a culture of sustainability. By training workers in sustainable practices and encouraging artisanal skills, the industry can create jobs and uplift communities, promoting a more equitable approach to production.

In conclusion, the evolution of blue dye factories represents a significant shift towards sustainable color production in the textile industry. By embracing natural methods, leveraging biotechnology, and prioritizing the principles of the circular economy, these factories are not only reviving a time-honored tradition but also setting new standards for an environmentally-conscious future. As awareness and responsibility grow, the once murky waters of dyeing are beginning to clear, revealing a vibrant spectrum of possibilities for a sustainable tomorrow.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

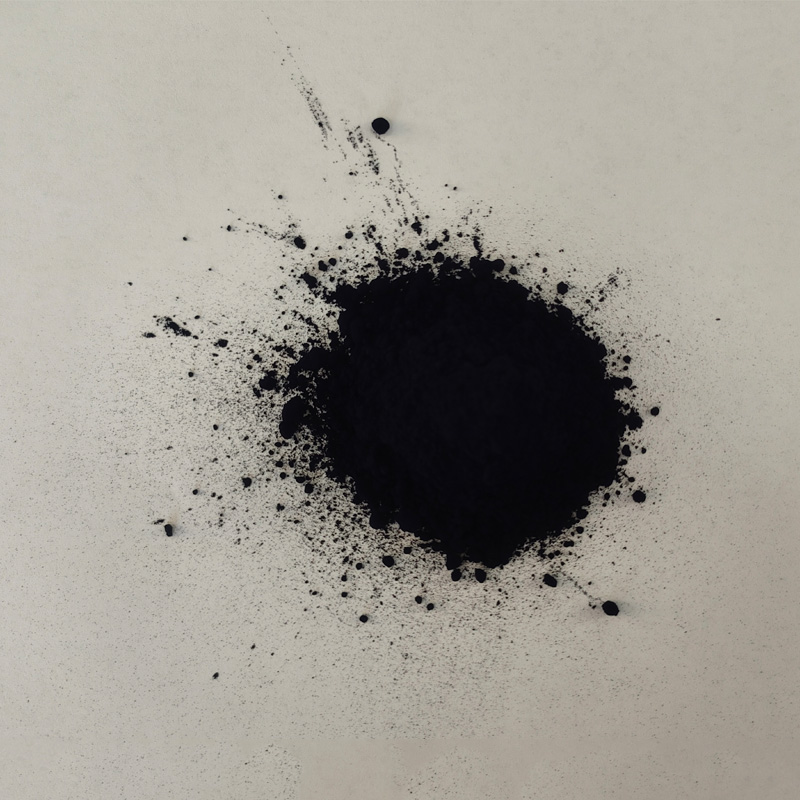

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.