Creating a Factory for Blue Dye Production Solutions

The Journey of Crafting Blue Dye A Glimpse into a Blue Dye Factory

The elegance of blue is a theme that has fascinated mankind for centuries, bringing artistry, culture, and history together in a vivid tapestry. At the heart of this fascination lies the production of blue dye, a process that has evolved dramatically over the years. Exploring the inner workings of a blue dye factory reveals not just the complexities of dye creation, but also its significance across various realms, from textiles to art.

Historically, blue dye was a luxury, often reserved for the elite. The earliest known blue dye came from the indigo plant, whose deep hues character have captured the imagination of countless cultures worldwide. The journey of the blue dye begins with the harvesting of indigo leaves, followed by a fermentation process that unlocks the dye’s pigment. Traditionally, this process was labor-intensive and time-consuming, requiring skilled artisans to ensure quality.

The Journey of Crafting Blue Dye A Glimpse into a Blue Dye Factory

In the heart of the factory, towering machines hum with energy as they churn out vibrant blue hues. The dyeing process begins with preparing the fabric—be it cotton, silk, or synthetic materials—which undergoes pre-treatment to enhance dye uptake. In dedicated dyeing machines, fabrics are immersed in a vat of indigo dye. The magic of chemistry takes over here; oxidation plays a crucial role as the fabric transforms from a light, muted color into a rich, deep blue upon exposure to air.

make blue dye factory

Quality control is a crucial element of the production line. Every batch of dye must be tested not only for color consistency but also for fastness, ensuring that the vibrant blue does not fade over time. Dye technicians meticulously analyze samples, using spectrophotometers and other instruments to guarantee that each production meets the highest standards.

While technology has revolutionized dye production, the artistry of dyeing remains. Many factories offer workshops and tours, showcasing the traditional methods of indigo dyeing alongside modern techniques. Visitors can learn the intricacies of Shibori, a Japanese dyeing technique that involves intricate folding and binding to create stunning patterns on fabric. Such workshops bridge the gap between ancient traditions and contemporary practice, fostering an appreciation for the artistry behind the dye.

Sustainability has also become a significant focus in blue dye factories. With increasing awareness of environmental issues, many manufacturers are exploring eco-friendly alternatives to traditional dye processes. Innovations like the use of plant-based dyes and closed-loop systems that recycle water and minimize waste are now at the forefront of the industry. Factories that prioritize sustainability not only reduce their environmental footprint but also cater to a growing consumer demand for ethically produced goods.

The role of blue dye extends beyond fashion and textiles. It plays a vital part in home décor, interior design, and even culinary arts, where natural dyes are used to enhance the visual appeal of dishes. The versatility of blue dye has woven itself into the fabric of our daily lives, influencing trends and inspiring creativity across various domains.

In conclusion, visiting a blue dye factory is not just an exploration of a production process; it is a journey through history, culture, and artistry. The evolution of blue dye from its historical roots to modern innovations exemplifies the dynamic relationship between craft and industry. As we continue to embrace both traditional techniques and sustainable practices, the story of blue dye will undoubtedly evolve, painting our world with its timeless brilliance.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

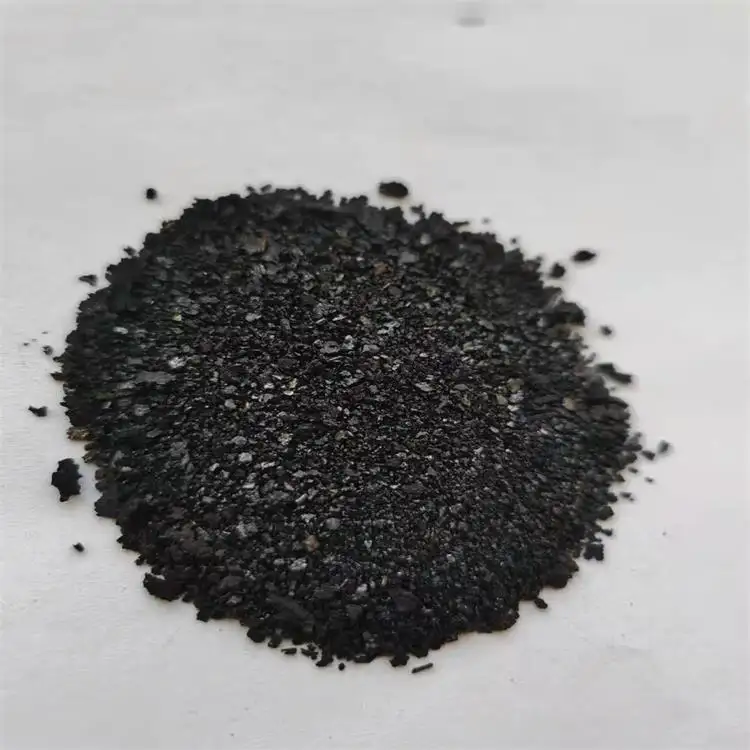

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.