Suppliers for Mixing Indigo Powder and Their Quality Options

Mixing Indigo Powder A Guide for Suppliers

Indigo powder, derived from the leaves of the indigo plant, has a rich history that dates back thousands of years. Its deep blue color has been sought after in textiles, art, and even cosmetics. As the demand for natural dyeing methods increases, suppliers are constantly exploring the best practices for mixing and using indigo powder effectively.

One of the essential aspects of working with indigo powder is achieving the right mix for your specific application, whether it's for dyeing fabrics, creating paints, or formulating cosmetics. The color quality of indigo is influenced by several factors, including the source of the powder, the method of extraction, and how it's mixed into a solution.

Mixing Indigo Powder A Guide for Suppliers

Mixing indigo powder can be a bit challenging due to its unique properties. The dye must be reduced to release its color, which typically requires a reduction agent such as sodium hydroxide or fructose. Understanding the chemistry behind this process is crucial for suppliers who want to provide the best products to their clients. Using the correct ratios and following precise mixing instructions is essential for achieving vibrant, long-lasting colors.

mixing indigo powder suppliers

Temperature and pH levels also play significant roles in the mixing process. Maintaining a slightly alkaline environment helps in the reduction process, while the temperature should be kept within a specific range to prevent any degradation of the dye. Suppliers must educate their customers on these factors to ensure optimal results.

In addition to practical tips for mixing, suppliers should consider offering a variety of indigo products, including powdered indigo, paste form, and even pre-reduced liquid dye. Providing various options caters to different customer needs and preferences, allowing for greater flexibility in applications.

Lastly, marketing indigo products effectively requires storytelling. Sharing the history, sustainability, and cultural significance of indigo can attract a clientele interested in more than just a product—they are looking for an experience. By fostering an understanding and appreciation for indigo, suppliers can build lasting relationships with their customers.

In conclusion, mixing indigo powder involves not only technical expertise but also a commitment to quality and sustainability. By focusing on high-quality materials and educating clients on the mixing process, suppliers can position themselves as trusted leaders in the indigo market.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

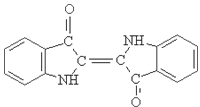

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.