Natural Indigo Dye Factory - Authentic Indigo Products & Sustainable Dyeing Solutions

The Revival of Natural Indigo Dye A Look into Sustainable Practices at Indigo Dye Factories

In recent years, there has been a remarkable resurgence in the popularity of natural dyes, particularly indigo. Known for its vibrant blue hue, indigo has been used for centuries in textiles around the world. As consumers become more environmentally conscious, the revival of natural indigo dye factories has garnered attention, blending tradition with sustainable practices.

The Revival of Natural Indigo Dye A Look into Sustainable Practices at Indigo Dye Factories

At a typical natural indigo dye factory, the journey from plant to pigment begins with the careful cultivation of indigo plants. Farmers practicing organic agriculture typically grow these crops without synthetic pesticides or fertilizers, which helps preserve the soil and local ecosystem. Once harvested, the leaves are processed to extract the indigo pigment. This process often involves the use of traditional techniques, including soaking and fermenting the leaves in water. The resulting indigo dye can then be used to create stunning textiles.

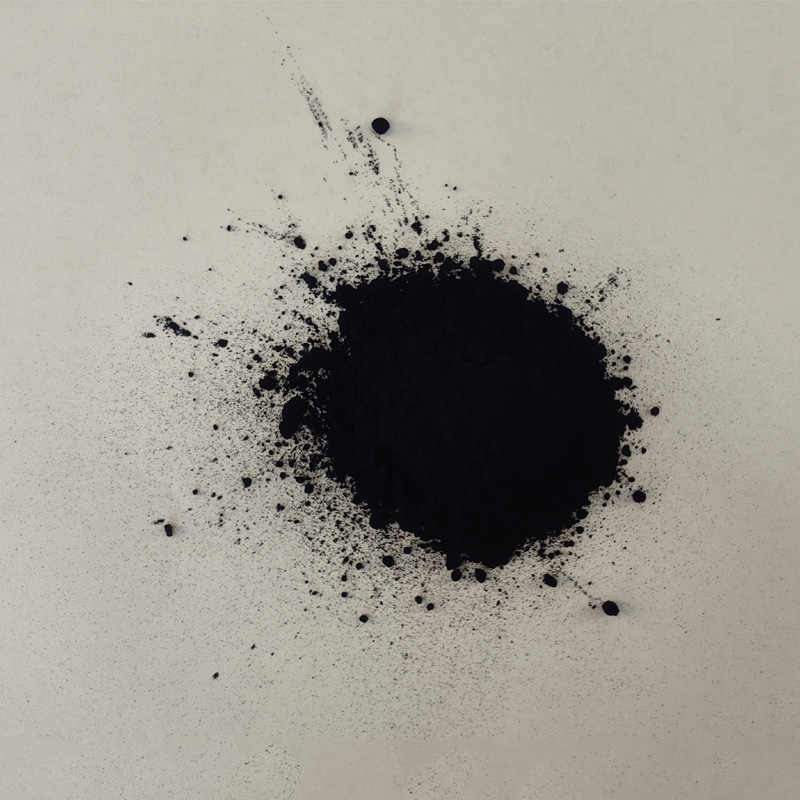

natural indigo dye factory

One of the most exciting aspects of natural indigo dye factories is their commitment to sustainable practices. Many of these facilities are incorporating innovative techniques to reduce water consumption and waste. For instance, some factories implement closed-loop systems to recycle water used in the dyeing process, significantly lowering their environmental footprint. Additionally, by emphasizing the use of local resources and labor, these factories contribute to the economic development of their communities, providing jobs and preserving traditional crafts.

Consumers are increasingly drawn to products made with natural indigo due to their uniqueness and limited environmental impact. Each batch of indigo-dyed fabric has its own character, resulting in variations in color and texture that synthetic dyes cannot replicate. This imperfection, celebrated in the world of slow fashion, encourages individuals to appreciate craftsmanship and support ethical production practices.

Moreover, the rise of natural indigo dye factories has sparked a renewed interest in traditional textile arts. Workshops and educational programs are being offered to teach new generations the craft of dyeing with indigo, thus ensuring that these techniques are passed down. This movement not only celebrates cultural heritage but also aligns with a global shift toward sustainability.

In conclusion, the resurgence of natural indigo dye factories represents more than just a trend; it signifies a movement toward more sustainable and responsible practices in the textile industry. By reviving ancient techniques and prioritizing ecological balance, these factories are helping to reshape consumer values and promoting a deeper connection between people and the environment. As we move forward, supporting natural indigo dye production is a step towards a more sustainable and colorful future.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.