natural dye indigo factories

The Significance of Natural Dye Indigo Factories

Indigo, a deep blue dye derived from the leaves of the indigo plant, has been utilized for thousands of years across various cultures and regions. Once a highly sought-after commodity, indigo was considered blue gold due to its vibrant color and the labor-intensive process of extracting it. Despite the rise of synthetic dyes in the 19th century, natural dye indigo factories have experienced a resurgence in recent years, driven by a growing consumer demand for sustainable and eco-friendly products. In this article, we will explore the significance of natural dye indigo factories, their cultural heritage, environmental benefits, and the craftsmanship involved in producing this exquisite dye.

Cultural Heritage

Historically, indigo dyeing has played a pivotal role in many cultures. In countries like India, Japan, and West Africa, indigo is more than just a color; it is a symbol of cultural identity and tradition. The art of indigo dyeing has been passed down through generations, with each region developing its techniques and patterns. For instance, Japan's Shibori and India’s Bandhani techniques showcase the diversity in the application of indigo dye.

Natural dye indigo factories often serve as hubs for preserving these traditional practices. By reviving ancient methods of dyeing, these factories not only contribute to the economy but also sustain cultural heritage. Workshops and training programs conducted by these factories help local artisans hone their skills and ensure that the traditional methods of indigo dyeing are not forgotten.

Environmental Benefits

As the world becomes increasingly aware of the environmental ramifications of synthetic dyes, the natural dye industry has gained attention for its sustainability. Synthetic dyes are often manufactured using harmful chemicals that can contaminate water sources and impact local ecosystems. In contrast, natural indigo dye is derived from the fermentation of plant leaves, making it a non-toxic and biodegradable option.

Natural dye indigo factories typically prioritize environmentally friendly practices. Many of them focus on organic farming methods that avoid the use of synthetic pesticides or fertilizers, ensuring that the indigo plants are grown sustainably. Additionally, these factories often engage in water conservation practices, using less water in their dyeing processes compared to conventional methods. This commitment to sustainability appeals to a growing consumer base interested in ethical fashion and eco-friendly products.

natural dye indigo factories

Craftsmanship

The production of natural indigo dye is a meticulous process that embodies the essence of craftsmanship. It begins with the cultivation of indigo plants, which require specific climate conditions and careful tending. Once harvested, the leaves are fermented in water, leading to the chemical transformation that produces the dye.

The dyeing process itself is a labor of love, involving multiple stages. Fabrics are typically pre-treated to enhance dye absorption, and then submerged in vats containing the indigo solution. As artisans remove the fabric from the vat, it undergoes a color change from green to blue upon exposure to oxygen—a fascinating transformation that never ceases to amaze. This art requires patience, skill, and a deep understanding of the materials.

Each piece dyed with natural indigo carries unique characteristics, including variances in color and texture. This individuality is increasingly cherished in a market that seeks authenticity and uniqueness, particularly in textiles and fashion.

Conclusion

Natural dye indigo factories represent a confluence of cultural heritage, environmental consciousness, and craftsmanship. They not only preserve traditional art forms but also contribute to the promotion of sustainable practices in the textile industry. As consumers become more mindful of their choices, the demand for natural, ethically produced goods continues to rise.

By supporting indigo factories, we not only acknowledge and uplift traditional artisans but also promote a more sustainable and responsible approach to fashion. The revival of indigo dyeing offers a glimpse into a world where craftsmanship meets ecological awareness, providing a richer understanding of the stories behind the textiles we wear. In doing so, we are reminded of the beauty and complexity of the natural world, and the role we play in preserving it. As we embrace this resurgence, we contribute not only to our wardrobes but also to a sustainable future.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

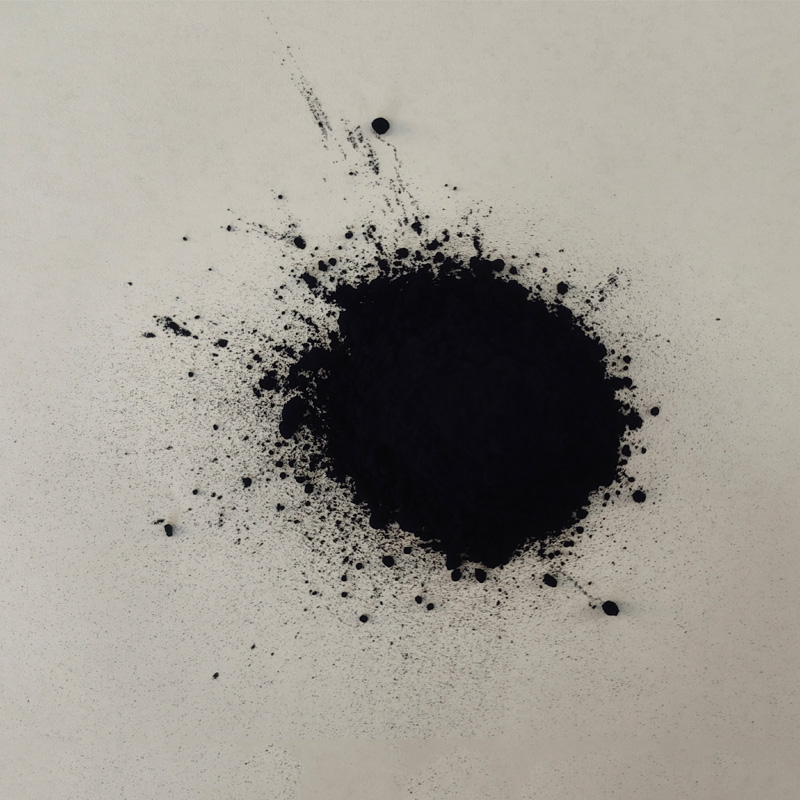

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.