Natural Indigo Fabric Production and Sustainable Dyeing Techniques in Modern Factories

The Resurgence of Natural Indigo Dyed Fabric A Tradition Reimagined

In an age increasingly characterized by fast fashion and synthetic dyes, the revival of natural indigo dyed fabric represents not only a return to traditional craftsmanship but also a sustainable approach to textile production. The rich history and culturally significant legacy of indigo dyeing are being celebrated anew in factories around the world, particularly those committed to maintaining environmental integrity and preserving artisanal skills.

Indigo, one of the oldest dyes known to humanity, has been used for millennia, with roots tracing back over 5,000 years to ancient civilizations in India and Mesopotamia. The dye is derived from the leaves of the indigo plant, primarily Indigofera tinctoria, which contains a compound called indican that, through fermentation and oxidation, transforms into the vibrant blue hue sought after by artisans and fashion designers alike.

The Resurgence of Natural Indigo Dyed Fabric A Tradition Reimagined

One common feature of these factories is their commitment to traditional dyeing techniques, often passed down through generations. Artisans in these facilities use age-old knowledge and skills, combining it with modern sustainability practices to create fabrics that are not only beautiful but also ethically produced. For instance, many factories employ a process called shibori, a Japanese tie-dye technique that allows for unique patterns that emerge during the dyeing process. This method not only enhances the aesthetic appeal of the fabric but also reflects the individuality of each piece, making handcrafted textiles increasingly desirable among consumers.

natural indigo dyed fabric factory

The labor-intensive process of creating natural indigo dyed fabric is a testament to the artisans' commitment to their craft. It begins with the careful cultivation of indigo plants, which require specific soil conditions and weather to thrive. Once harvested, the leaves are processed through fermentation, a delicate and time-consuming method that produces the dye. This dyeing process can take several days, during which the fabric is immersed in vats of indigo, turning from green to deep blue through repeated soaking and oxidation.

Further enhancing the appeal of indigo dyed fabric is its adaptability in fashion and interior design. Designers are increasingly integrating natural indigo into their collections, utilizing its vibrant hue and unique textures to create standout pieces. From jeans and shirts to home textiles like curtains and upholstery, the versatility of indigo fabric is unmistakable. This has led to a growing niche market where consumers are no longer seeking mass-produced items but are instead investing in quality, handcrafted pieces that tell a story.

In response to this growing interest, many natural indigo dyed fabric factories are expanding their operations and opening their doors to consumers. Workshops and tours offer visitors a behind-the-scenes look at the dyeing process, allowing them to appreciate the time and effort that goes into each piece. Such experiences not only educate consumers about sustainable practices but also empower them to make informed choices about their clothing and home decor.

Looking to the future, the natural indigo dyed fabric industry holds significant potential for further growth. As sustainability becomes a priority across many sectors, the demand for ethically produced textiles will likely continue to rise. Supporting these traditional factories, which value craftsmanship and environmental stewardship, will be crucial in promoting a more sustainable future for the fashion industry.

In conclusion, the natural indigo dyed fabric factory embodies a harmonious blend of tradition and innovation. It stands at the forefront of a movement that seeks to reconcile the elegance of artisanal practices with the pressing need for sustainability. As consumers increasingly seek products with a purpose, the allure of naturally dyed fabrics, rich in history and ecological mindfulness, is set to thrive, ensuring that the legacy of indigo will continue to inspire generations to come.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

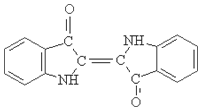

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.