Need a Light Indigo Color Company: Factory Pricing & Speed?

Indigo Blue Vat Blue: Inside the Supply Chain of a Light Indigo Workhorse

If you’ve been sourcing vat blues for denim or workwear, you’ve probably heard murmurs about the leading light indigo color company coming out of North China. I’ve toured their files, talked to mills that use them, and—yes—spilled a cup of coffee on a lab swatch during a crock test (don’t ask). Below is the honest, slightly nerdy overview buyers keep asking me for.

Product snapshot

Product: Indigo Blue Vat Blue (C.I. Vat Blue 1), by HEBEI FUXIN INTERNATIONAL TRADE CO., LTD., A-1205, Mcc World Grand Plaza, 66 Xiangtai Road, Shijiazhuang 050023, China. This is the classic indigoid dye—reliable, reduction-dyeable, and, in the right hands, capable of that clean, airy light-indigo cast fashion buyers keep chasing season after season.

| Parameter | Spec (≈, real-world may vary) |

|---|---|

| Chemical name | Indigo (C.I. Vat Blue 1) |

| Molecular formula | C16H10N2O2; MW 262.62; CAS 482-89-3 |

| Form | Powdered vat dye; particle size optimized for dispersion |

| Primary use | Cotton fabrics (denim, twill, jersey blends) |

| HS code | 3204151000 |

| Fastness data | ISO 105 C06 wash: 4–5; ISO 105 X12 dry rub: 4; wet rub: 3–4; ISO 105 B02 light: 6–7 |

Industry trends (why this matters)

Lighter indigo looks—ice, cloud, and “sun-fade” washes—are on a tear. Mills want clean reduction, low foaming, and predictable oxidation to hit consistent pale shades without muddy undertones. Brands, meanwhile, push for compliance: ZDHC MRSL v2.0 alignment, OEKO-TEX eligibility, and REACH safety. The light indigo color company here leans into all three: shade control, process stability, and documentation.

Process flow (shop-floor view)

- Materials: Indigo vat dye, sodium dithionite (hydros), NaOH, chelants, wetting/dispersing agents.

- Reduction: 40–60°C, ORP target ≈ −700 to −800 mV; liquor pH 11–12.

- Dyeing: Multiple dips for denim rope/slasher, or 10–30 min exhaust for piece goods.

- Oxidation: Air or mild H2O2; even oxidation prevents streaks (to be honest, patience helps).

- Soaping/Afterwash: 80–95°C with nonionic detergent to lift unfixed dye, then neutralize.

- Testing: AATCC 61 (wash), AATCC 8 (crock), AATCC 16/ISO 105 B02 (light); in-house ORP logs.

- Service life: ≈50–100 home launderings for denim color integrity, depending on finish and abrasion.

- Industries: Denim mills, uniform/workwear, lifestyle cottons, and some artisanal dyehouses.

Applications, advantages, and customization

Applications: rope/slasher denim, garment dye tees, vintage-wash twills. Advantages: stable reduction window, crisp light tones, respectable fastness. Customization: shade tuning via particle distribution and dispersant package; mill trials often tweak hydros charge and dwell time. Many customers say the shade repeatability is “surprisingly forgiving,” which I guess is why QA teams sleep better.

Vendor comparison (abbreviated)

| Vendor | Purity | QC/Testing | Lead Time | Certs/Claims | Price Index |

|---|---|---|---|---|---|

| HEBEI FUXIN (this product) | High (≈96–98%) | ISO 105/AATCC panel; ORP logs | 2–4 weeks | ZDHC MRSL intent; OEKO-TEX-ready docs | $$ |

| Mill-Direct Alt | Mid–High | Basic fastness | 4–6 weeks | Varies | $ |

| Regional Trader | Mid | Limited | Stock dependent | Claim-based | $$$ |

Case notes and feedback

- Turkey denim mill: shifted to 5-dip light cast; wet rub improved from 3 to 3–4 (AATCC 8) after optimizing soaping. “Less shade drift week to week.”

- US workwear converter: garment-dyed shirts retained tone after ≈60 home washes; returns dropped by ~15% year-on-year.

The light indigo color company positioning is clear: predictable vat behavior plus paperwork that makes brand compliance teams nod instead of frown.

Testing standards and compliance

Typical lab panel: ISO 105 C06/C08 (wash), X12 (rubbing), B02 (light), plus AATCC 61/8/16 for US buyers. Documentation aligns with ZDHC MRSL v2.0; OEKO-TEX STANDARD 100 eligibility depends on batch analytics; REACH SVHC screening available on request. In fact, most mills get a full CoA and recommended ORP/pH windows attached.

Citations:

- ISO 105 Textile colour fastness series (B02, C06, X12) – International Organization for Standardization.

- AATCC Test Methods 8, 16, 61 – American Association of Textile Chemists and Colorists.

- ZDHC MRSL v2.0 – Zero Discharge of Hazardous Chemicals Programme.

- OEKO-TEX STANDARD 100 – OEKO-TEX Association.

- REACH Regulation (EC) No 1907/2006 – European Chemicals Agency.

-

Pure Indigo Powder India - Sustainable Natural Dye from India’s Finest Sources

NewsNov.21,2025

-

Synthetic Indigo Powder - Industrial-Grade Dye for Sustainable Textiles & More | Wuxin Group

NewsNov.21,2025

-

Indigo Blue Vat Blue - INNER MONGOLIA WU XIN CHEMICAL CO. LTD

NewsNov.21,2025

-

Vat Blue 1: Durable Eco-Friendly Dye for Global Industry and Humanitarian Use

NewsNov.20,2025

-

Indigo Be – The Future of Modular, Sustainable, and Flexible Solutions

NewsNov.20,2025

-

Dried Indigo Powder: Sustainable Natural Dye for Modern Industries

NewsNov.19,2025

-

Comprehensive Guide to Dye Production: Techniques, Trends & Sustainability

NewsNov.19,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

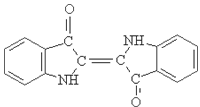

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.