odm indigo dyeing machine

The Advancements and Benefits of ODM Indigo Dyeing Machines

Indigo dyeing has a long-standing history that traces back thousands of years, commonly associated with the creation of blue denim fabric. In the textile industry, the demand for high-quality indigo dyes has increased significantly, leading to advances in dyeing technologies. One such innovation is the ODM (Original Design Manufacturer) indigo dyeing machine, which has transformed the dyeing process, making it more efficient, environmentally friendly, and economically viable.

Overview of ODM Indigo Dyeing Machines

ODM indigo dyeing machines are specialized equipment designed to streamline the process of dyeing textiles with indigo. These machines incorporate advanced technologies that automate various steps of the dyeing process, enhancing productivity and accuracy. Unlike traditional dyeing methods, which often rely heavily on manual labor and can be time-consuming, ODM machines enable manufacturers to achieve consistent, high-quality results in a fraction of the time.

The machinery typically features an integrated system for dye application, rinsing, and drying, all in one unit. This integration not only reduces the labor involved but also minimizes the risk of human error, ensuring uniformity and precision in color application. Moreover, many ODM machines come equipped with state-of-the-art control systems that allow for real-time monitoring of the dyeing process, providing manufacturers with actionable insights to optimize their operations.

Advantages of ODM Indigo Dyeing Machines

1. Efficiency and Speed One of the primary advantages of using ODM indigo dyeing machines is the significant reduction in dyeing time. Traditional indigo dyeing processes can take hours or even days to achieve the desired shade. In contrast, ODM machines can complete the dyeing process within a shorter time frame, enhancing production rates and meeting the ever-increasing market demands.

odm indigo dyeing machine

2. Consistent Quality The automated nature of ODM machines ensures a high level of consistency in dyeing results. Parameters such as temperature, dye concentration, and timing can be tightly controlled, leading to an even application of dye across all textiles. This consistency is crucial for brands that prioritize quality and seek to maintain their reputations in a competitive market.

3. Environmental Impact Environmental sustainability has become a critical consideration in the textile industry. ODM indigo dyeing machines are designed with eco-friendly practices in mind, often reducing water usage and chemical waste compared to traditional methods. Some machines utilize recycling systems to minimize environmental impact further. This not only benefits the planet but also helps manufacturers comply with increasing regulatory standards related to pollution and waste management.

4. Cost-Effectiveness Though the initial investment in ODM machines can be significant, the long-term financial benefits typically outweigh the costs. Increased efficiency, reduced labor needs, and lower material waste all contribute to overall cost savings. This allows companies to maximize their profit margins while offering competitive pricing to their customers.

5. Versatility ODM indigo dyeing machines are not limited to denim alone. They can be adapted for various types of fabrics, expanding the range of products that manufacturers can offer. This versatility is particularly beneficial for companies looking to diversify their product lines and cater to different markets.

Conclusion

In conclusion, ODM indigo dyeing machines represent a revolutionary step forward in the textile industry, combining technological innovation with environmental responsibility. As demand for high-quality, sustainable textiles continues to rise, the adoption of these advanced machines is likely to play a crucial role in shaping the future of dyeing processes. Manufacturers that invest in ODM technologies can expect improved efficiency, superior quality, and a positive environmental impact, positioning themselves favorably in an increasingly competitive market. The shift toward automated, eco-friendly dyeing solutions not only benefits businesses but also contributes to a more sustainable future for the textile industry as a whole.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

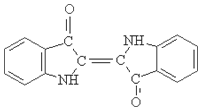

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.