oem indigo dyestuff

Understanding OEM Indigo Dyestuff A Deep Dive into Its Importance and Applications

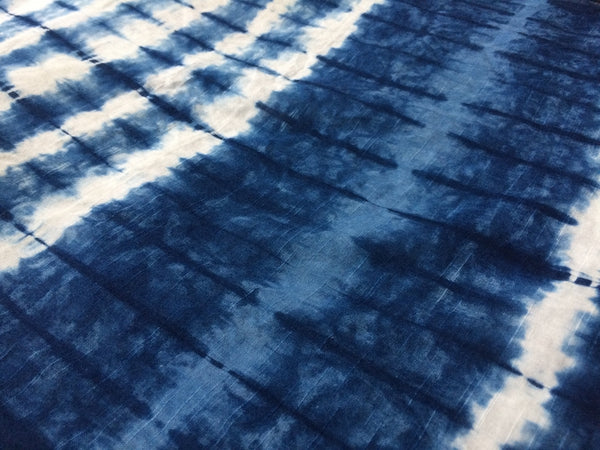

Indigo dyestuff, specifically in the context of OEM (Original Equipment Manufacturer), plays a crucial role in the textile and dyeing industries. Indigo, a natural dye derived from the leaves of the indigo plant, has been used for centuries to create its distinctive deep blue color. In modern manufacturing, the term OEM refers to companies that produce products or components that are then marketed by another company under its own branding. This concept is particularly significant in the realm of indigo dyestuff, as multiple manufacturers can supply various forms of indigo dyes tailored for specific applications.

Understanding OEM Indigo Dyestuff A Deep Dive into Its Importance and Applications

The applications of indigo dyestuff are extensive. Primarily, it is renowned for its use in dyeing denim, which has been a staple in fashion for decades. The unique properties of indigo allow for the development of various shades and finishes in denim products, providing designers with versatility in their creations. Beyond denim, indigo is also utilized in other textiles, home furnishings, and even in artistic applications like fabric painting. The resurgence of interest in sustainable and natural dyes has further fueled the popularity of indigo, as consumers seek eco-friendly alternatives to synthetic dyes.

oem indigo dyestuff

Moreover, the production of indigo dyestuff has evolved with technological advancements. While natural indigo remains prevalent, synthetic indigo has gained attention for its consistent quality and production efficiency. Companies in the OEM arena often provide both natural and synthetic options, allowing brands to choose the best fit for their products. As sustainability becomes an increasingly important factor in consumer purchasing decisions, many dye manufacturers are also exploring bio-based production methods and sustainable sourcing of raw materials for their indigo dyestuff.

Quality control is paramount in the production of OEM indigo dyestuff. Rigorous testing and standards ensure that the dyes are not only effective in color application but also safe for use in textiles. This is particularly important given the global emphasis on health and safety regulations in manufacturing. Companies relying on indigo dyes need assurance that their products will perform reliably and meet consumer expectations.

In conclusion, OEM indigo dyestuff stands as a testament to the innovative advancements within the dye industry. It offers significant advantages in terms of quality, versatility, and sustainability. As the world continues to emphasize eco-friendly practices and high-quality products, indigo dyestuff—whether natural or synthetic—holds a promising future in various industrial applications. Partnering with the right OEM manufacturers can ensure that brands deliver not only beautiful colors but also meet the growing demand for responsible manufacturing practices in today’s market.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.