High Quality OEM Blue Dye Powder for Various Applications and Industries

Understanding OEM Blue Dye Powder Applications and Benefits

OEM blue dye powder has gained significant attention in various industries due to its vibrant color, versatility, and the ability to be customized according to specific needs. Original Equipment Manufacturer (OEM) blue dye powder is produced for businesses looking to incorporate this colorant into their products, whether in textiles, plastics, cosmetics, or food industries. This article explores the applications, benefits, and manufacturing processes associated with OEM blue dye powder.

Understanding OEM Blue Dye Powder Applications and Benefits

In the plastic manufacturing sector, OEM blue dye powder is crucial for creating visually appealing and marketable products. By integrating the dye into the plastic before it is molded, manufacturers can produce items with evenly distributed color, increasing their aesthetic value. This is particularly important for consumer products where presentation can significantly influence purchasing decisions.

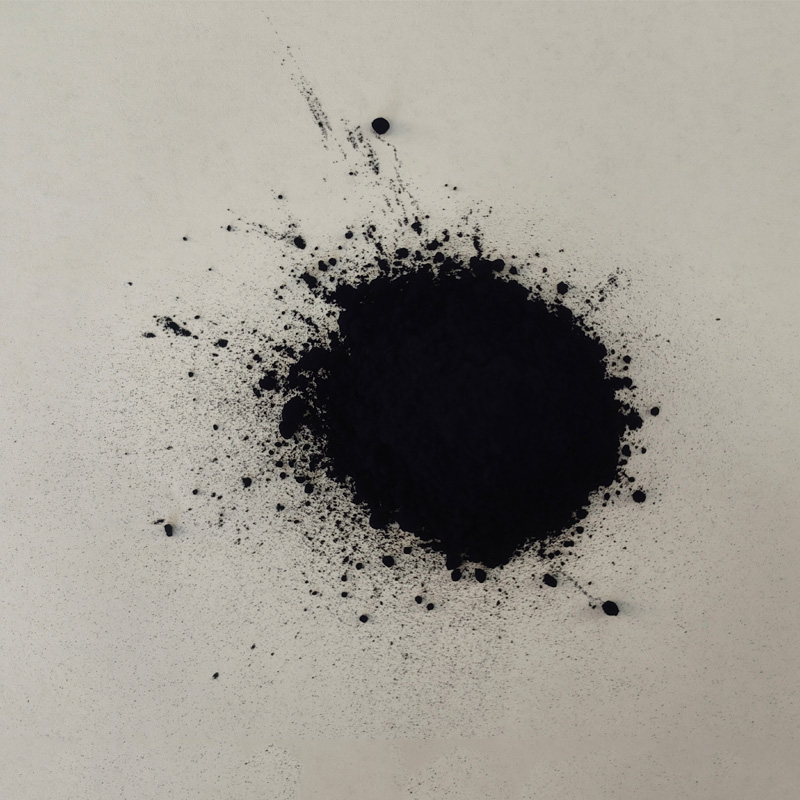

oem blue dye powder

Cosmetic manufacturers also utilize OEM blue dye powder to create vibrant formulations for items such as eyeshadows, nail polishes, and skincare products. The ability to customize the dye allows for unique shades that cater to specific consumer preferences. Additionally, adhering to safety and regulatory standards is paramount in cosmetics; therefore, OEM suppliers often ensure that their blue dye powder is compliant with relevant regulations.

In the food industry, OEM blue dye powder is utilized in products ranging from candies to beverages. Food-grade dyes must adhere to strict regulations, and reputable OEM suppliers provide certifications to guarantee the safety of their products. This ensures that consumers can enjoy colorful food products without health concerns.

The benefits of using OEM blue dye powder extend beyond its vibrant color. Customization options allow businesses to develop unique shades tailored to their brand identity, enhancing product differentiation in the market. Furthermore, working directly with OEM suppliers can foster a strong partnership, ensuring a consistent supply of high-quality materials.

In conclusion, OEM blue dye powder serves as an essential colorant across multiple industries. Its versatility, customization options, and reliability make it an invaluable resource for manufacturers looking to create products that stand out in a competitive market. With ongoing innovations in dye technology, the future of OEM blue dye powder appears promising.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.