Natural Indigo Plant Dye Sourcing for OEM Production and Customization Options

Exploring OEM Dye from the Indigo Plant A Sustainable Approach to Color

Indigo, one of the oldest dyes in human history, is derived from the leaves of the indigo plant, primarily Indigofera tinctoria. The vibrant blue shade produced by indigo dye has captivated artisans and consumers alike for centuries, with its roots deeply embedded in cultures around the globe. In recent years, the rise of sustainable fashion and eco-friendly products has rekindled interest in natural dyes, prompting a resurgence in the popularity of indigo dye, especially through Original Equipment Manufacturer (OEM) channels.

The Indigo Plant and Its Historical Significance

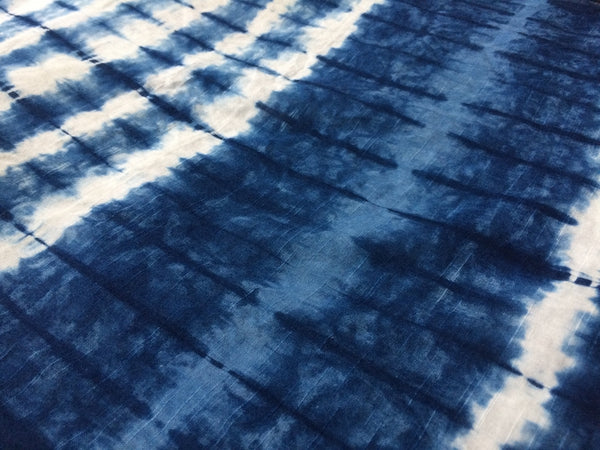

The use of indigo dates back over 6,000 years, with its origins traced to ancient civilizations in India, Egypt, and China. Historically, indigo dyeing was a labor-intensive process that involved fermenting the plants to extract the coloring agent. Different cultures developed unique techniques; for instance, the tie-dye method known as shibori in Japan showcases indigo in intricate patterns. As trade routes expanded, indigo became a precious commodity, sometimes referred to as blue gold.

The Process of Extracting Dye from Indigo

The extraction of dye from the indigo plant involves several steps. First, the leaves are harvested and then soaked in water to initiate fermentation, which converts the natural compounds into a soluble form. This solution, rich in indigo, can then be oxidized, leading to the formation of the characteristic blue dye. The indigo dye can be dried and powdered or used in a liquid form, providing flexibility for manufacturers and artisans.

The OEM Advantage in Indigo Dye Production

The term OEM refers to companies that design and manufacture products based on another company’s specifications. In the context of indigo dye, OEM businesses can produce dyed textiles, garments, and other products tailored to specific customer requirements. This model allows brands to offer customized solutions while capitalizing on the unique properties of natural indigo dye.

oem dye from indigo plant

One of the key advantages of using OEM for indigo dye is efficiency. Manufacturers can focus on their core competencies while outsourcing dye production. This collaboration fosters innovation, as experts in dyeing techniques work alongside brands to develop unique applications and formulations. Moreover, the use of OEM can lead to a reduction in production costs and shorter time-to-market cycles.

Sustainable Practices in Dye Production

As the fashion industry grapples with its environmental impact, the sustainable attributes of indigo dyeing have gained prominence. Unlike synthetic dyes, which can contain harmful chemicals, indigo is natural and biodegradable. When produced through OEM channels, manufacturers can implement eco-friendly practices such as optimizing water usage and recycling effluents, thus minimizing waste and pollution.

Furthermore, many modern OEM dye houses are embracing organic farming practices for their indigo crops. These initiatives not only preserve biodiversity but also enhance the livelihoods of local farmers. By choosing sustainably sourced indigo, brands can appeal to environmentally conscious consumers who are increasingly demanding transparency in the sourcing of natural products.

Corporate Social Responsibility and Community Engagement

Brands working with OEM partners can also integrate corporate social responsibility (CSR) into their operations. Investing in local communities where indigo is cultivated can create a positive impact. This includes providing fair wages to farmers, ensuring ethical labor practices, and supporting education and healthcare initiatives. Such efforts resonate strongly with consumers who prefer to support companies that prioritize social and environmental responsibility.

Conclusion

The resurgence of indigo dye, powered by OEM channels, represents a harmonious balance between tradition and modernity. As industries embrace sustainability, indigo’s rich history can be woven into contemporary narratives, offering not just a striking color but also a story of cultural significance and eco-consciousness. By leveraging OEM partnerships, brands can explore the depths of creativity and responsibility, promoting the beauty and sustainability of indigo dye in today’s market. As we continue to innovate, the allure of the indigo plant will undoubtedly thrive, painting our world in shades of blue while remaining rooted in respect for nature and communities.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.