oem indigo dyed cotton yarn

The Art and Impact of OEM Indigo Dyed Cotton Yarn

In the world of textiles, few materials hold as much significance and versatility as cotton. Among the various treatments and dyeing processes, indigo dyeing stands out for its rich history and vibrant results. Original Equipment Manufacturer (OEM) indigo dyed cotton yarn, in particular, has gained prominent attention in both fashion and industrial applications due to its unique characteristics, sustainability, and cultural implications.

Understanding Indigo Dyeing

Indigo dyeing is one of the oldest dyeing processes known to humanity. With origins dating back thousands of years, indigo has been utilized in different cultures, from the ancient Egyptians to the traditional artisans in India and Japan. The distinct deep blue color achieved through indigo dyeing is not merely aesthetic; it has significant cultural relevance, representing tradition, craftsmanship, and regional identity.

The dyeing process itself involves the fermentation of indigo leaves or synthetic indigo to create a soluble form that can be absorbed by cotton fibers. This deep-blue dye interacts beautifully with cotton, producing fabric that boasts durability and comfort. The ability to create different shades and patterns through techniques like shibori adds an artistic nuance that is both captivating and culturally significant.

The Role of OEM in Indigo Dyed Cotton Yarn Production

Original Equipment Manufacturing (OEM) plays a crucial role in the textile industry, especially in the production of indigo dyed cotton yarn. OEM companies specialize in manufacturing products that other companies brand and sell under their own names. This arrangement allows for flexibility, scalability, and access to specialized knowledge, particularly in niche markets like indigo dyed textiles.

Partnering with OEM providers enables brands to focus on their creative vision and marketing strategies while benefiting from the expertise of manufacturers who specialize in dyeing techniques, sustainable practices, and quality control. This collaboration ensures high-quality production of indigo dyed cotton yarn, meeting the needs of various sectors, from high fashion to practical use in home textiles.

Sustainability and Ethically Sourced Materials

oem indigo dyed cotton yarn

As consumers become increasingly conscious of the environmental impact of their purchases, the demand for sustainable materials and processes in the textile industry has risen significantly. Indigo dyed cotton yarn produced via OEM can often be manufactured with a focus on sustainability. Many OEM producers are now adopting organic cotton and natural dyeing techniques, allowing brands to offer environmentally friendly products.

By choosing to work with OEM partners that prioritize ethical practices, brands can reduce their carbon footprints and promote fair labor. This movement toward sustainability not only benefits the environment but also resonates with consumers who want to make responsible purchasing decisions.

Versatility of Indigo Dyed Cotton Yarn

One of the standout features of indigo dyed cotton yarn is its versatility. This yarn can be utilized in various applications, from fashionable garments to durable upholstery and artisanal crafts. The timeless beauty of indigo dye complements various styles, making it a popular choice among designers and creators alike.

Brands can explore innovative designs and incorporate indigo dyed cotton yarn into their collections, celebrating both classic and contemporary aesthetics. The unique fading properties of indigo also add an element of individuality, as each piece can develop a distinct character over time with use and washing. This uniqueness appeals to consumers seeking one-of-a-kind products.

Conclusion

In summary, OEM indigo dyed cotton yarn represents a fusion of tradition and modernity, craftsmanship, and innovation. With its rich history and cultural significance, indigo dyeing adds depth to textile products while addressing contemporary demands for sustainability and ethical production. The collaboration between brands and OEM producers ensures that the beauty of indigo dyed textiles can continue to thrive, evolving alongside shifting consumer preferences and environmental considerations.

As the textile industry navigates the complexities of the modern world, indigo dyed cotton yarn stands poised to remain a beloved choice for artisans, designers, and consumers alike. Its allure lies not only in its color and texture but also in the narratives it carries, connecting people to the generations of craftsmanship that preceded them.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

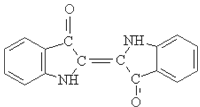

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.