Eco-friendly Pure Indigo Dye for OEM Applications and Sustainable Fashion Solutions

The Allure of OEM Pure Indigo Dye A Journey Through Color and Culture

Indigo dye has fascinated humanity for thousands of years, its deep, rich hue serving as a symbol of elegance and tradition in various cultures across the globe. The advent of OEM (Original Equipment Manufacturer) pure indigo dye has amplified its availability, allowing manufacturers to harness this time-honored dye while ensuring quality and authenticity.

The Historical Significance of Indigo

Indigo dye is derived from the leaves of the indigo plant, primarily Indigofera tinctoria. Unlike synthetic dyes that emerged in the 19th century, indigo has a history that dates back over 6,000 years. Ancient civilizations, including those in Egypt, India, and Peru, valued indigo for its vibrant color and its ability to resist fading. The indigo dyeing process was often a closely guarded secret passed down through generations, involving intricate techniques and rituals.

In India, indigo dyeing became a prominent artisanal practice, where artisans known as dhobis would work diligently to produce exquisite fabrics. The craftsmanship involved in creating indigo-dyed textiles is a testament to the deep cultural roots associated with this dye, making it an essential part of local economies and traditions.

The Transition to OEM Pure Indigo Dye

With the progression of technology and globalization, the textile industry has seen a shift towards more standardized production methods. OEM pure indigo dye emerged as a response to the growing demand for consistent quality while maintaining the essence of traditional indigo. The OEM process involves partnering with manufacturers who specialize in producing high-quality, pure indigo dye that meets strict industry standards.

This transition not only ensures the quality of the dye but also allows for the preservation of the traditional methods that have long surrounded indigo dyeing. Manufacturers can now produce indigo dye in larger quantities while maintaining the deep, luminous shades that artisans have cherished for centuries.

Benefits of OEM Pure Indigo Dye

oem pure indigo dye

1. Quality Assurance One of the standout features of OEM pure indigo dye is the emphasis on quality. Manufacturers rigorously test and ensure that the dye meets international standards, providing consistent results regardless of the batch. This is crucial for textile producers who rely on color accuracy across different runs.

2. Sustainability The production of OEM pure indigo often involves sustainable practices. Many manufacturers focus on environmentally friendly methods of cultivation and dyeing, using less water and avoiding harmful chemicals. As consumers become more eco-conscious, the demand for sustainable dye sources has risen significantly.

3. Cultural Preservation By supporting OEM pure indigo dye, consumers are indirectly contributing to the preservation of cultural heritage. Many OEM partners collaborate with local artisans and communities that have historically practiced indigo dyeing, ensuring that these skills are not lost and continue to thrive in modern industries.

4. Versatility OEM pure indigo dye is not limited to textiles; it has found applications in various fields including art, cosmetics, and even food. This versatility broadens its appeal and creates new opportunities for artisans and manufacturers alike.

The Future of OEM Pure Indigo Dye

As the textile industry continues to evolve, the future of OEM pure indigo dye looks promising. With the rise of fashion trends that celebrate authenticity and craftsmanship, indigo dye is reclaiming its place in modern design. Sustainable fashion, in particular, has embraced indigo for its storied past and eco-friendly potential.

Moreover, as retailers and consumers become more aware of the ethical implications of their choices, supporting OEM pure indigo dye signifies a commitment to sustainable practices and cultural appreciation. The notion of slow fashion advocates for quality over quantity, making indigo-dyed products an attractive option for conscious consumers.

Conclusion

OEM pure indigo dye embodies the convergence of heritage and modernity. It stands as a testament to the transformative power of color and culture, reminding us of the rich history embedded in each indigo hue. As we move forward, embracing indigo dye allows us not only to celebrate beauty but also to honor the traditions that have shaped our world. Through responsible sourcing and appreciation for craftsmanship, OEM pure indigo dye can continue to flourish, ensuring that its captivating allure remains alive for generations to come.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

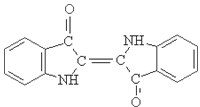

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.