Exploring the Rich Heritage of Traditional Indigo Dyeing Techniques and their Modern Applications

The Art of Traditional Indigo Dyeing An OEM Perspective

Indigo dyeing is an age-old craft that has captivated artisans and consumers alike with its vibrant hues and rich cultural significance. The use of indigo, a natural dye derived from the leaves of the indigofera plant, dates back thousands of years, traversing various cultures across Asia, Africa, and South America. In the context of Original Equipment Manufacturing (OEM), traditional indigo dyeing represents not only a unique artistic expression but also a viable business opportunity.

The Art of Traditional Indigo Dyeing An OEM Perspective

From an OEM standpoint, traditional indigo dyeing presents unique advantages. The growing demand for sustainable and eco-friendly products aligns perfectly with the use of natural dyes. Consumers are increasingly inclined toward products that not only meet aesthetic desires but also reflect environmental consciousness. Utilizing indigo dyeing methods, OEMs can cater to this niche market by offering products that are both beautiful and sustainable.

oem traditional indigo dyeing

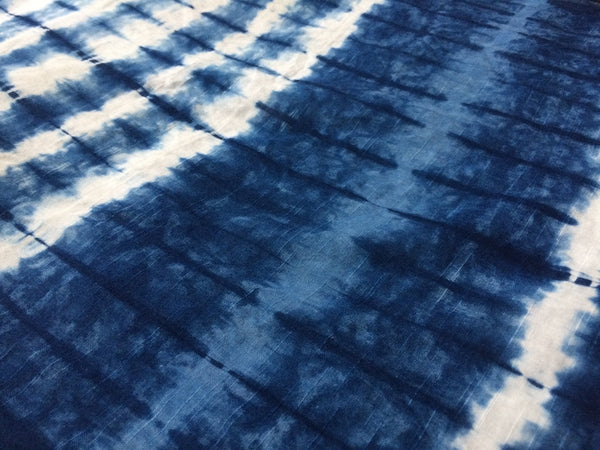

Another significant factor is the cultural heritage associated with indigo dyeing. Many regions have developed their distinctive techniques, patterns, and motifs that tell stories of their communities. For instance, the indigo textiles from Japan, known as Aizome, showcase unique tie-dye patterns. In West Africa, indigo is often used to create batik fabrics that reflect the vibrant identities of local tribes. By partnering with skilled artisans and incorporating traditional techniques into modern manufacturing processes, OEMs can preserve these cultural narratives while also promoting fair trade practices.

Incorporating traditional indigo dyeing into an OEM business model also necessitates a careful balance of innovation and respect for tradition. While modern technology can enhance efficiency and scalability, it is essential to maintain the authenticity and craftsmanship inherent in the dyeing process. This can involve training workshops for artisans and implementing sustainable practices throughout the supply chain.

Moreover, branding plays a pivotal role in the success of indigo-dyed products. OEMs should focus on storytelling, emphasizing the rich history and artistry behind each piece. Marketing strategies that highlight the traditional techniques and the artisans’ craftsmanship can bridge the gap between consumers and the products, creating a more meaningful purchase experience.

In conclusion, traditional indigo dyeing not only stands as an art form but also offers immense potential for OEM businesses seeking to merge creativity with sustainability. By embracing this time-honored craft, OEMs can capture the essence of tradition while catering to modern consumer demands, ultimately fostering a deeper appreciation for both the artistry of indigo dyeing and the cultural narratives intertwined with it. In the quest for innovation, the timeless allure of indigo continues to shine brightly.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.