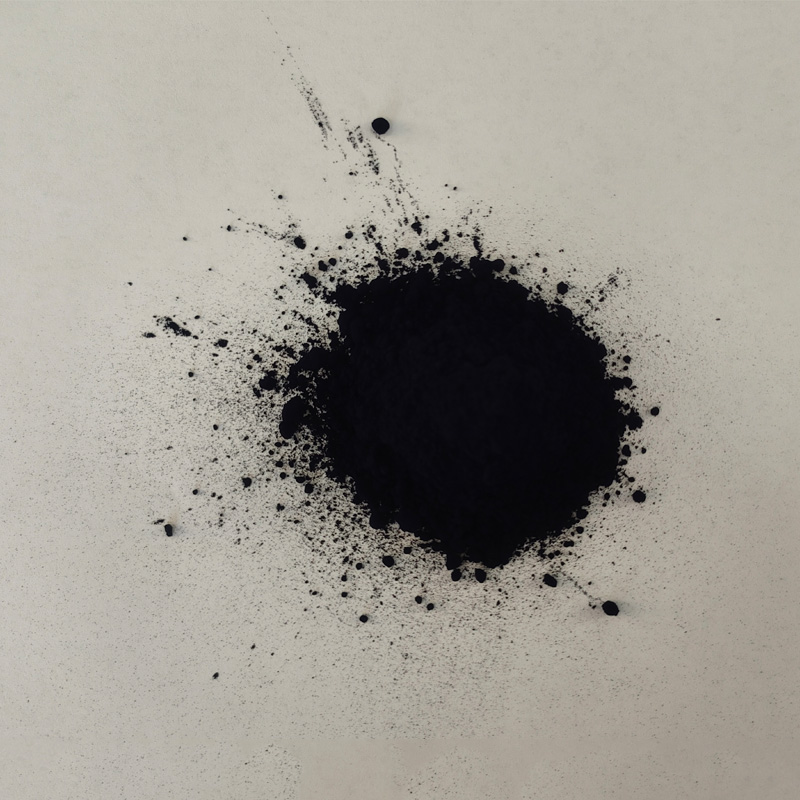

pre reduced indigo dye manufacturer

The Rise of Pre-Reduced Indigo Dye Sustainable Solutions in Textile Manufacturing

In recent years, the textile industry has witnessed a resurgence in the popularity of natural dyes, with pre-reduced indigo dye emerging as a prominent choice among manufacturers

. This innovative dyeing technique not only honors traditional practices but also aligns with contemporary demands for sustainability and eco-friendliness.Indigo dye, derived from the leaves of the Indigofera plant, has been used for centuries to color fabrics. However, traditional dyeing methods often involved complex processes that could be harmful to both the environment and the artisans involved. Enter pre-reduced indigo dye a modern solution that simplifies the dyeing process while preserving the rich history associated with indigo.

Pre-reduced indigo dye is created through a reduction process that converts indigo from its insoluble form to a soluble form, typically using a reducing agent like sodium hydrosulfite. This allows for a more straightforward application in dyeing fabrics, as the dye can be applied at lower temperatures and with less water. As a result, it greatly reduces water consumption and the energy required for dyeing processes, making it a more sustainable option for manufacturers.

pre reduced indigo dye manufacturer

One of the key advantages of pre-reduced indigo dye is its versatility. It can be used on a variety of textiles, including cotton, silk, and other natural fibers, allowing manufacturers to produce a wide range of products. Additionally, the vibrant blue hues that can be achieved with this dye continue to captivate consumers, making it a popular choice in the fashion industry.

Moreover, the increasing demand for sustainable practices in the textile industry has prompted manufacturers to adopt pre-reduced indigo dye as a visible commitment to environmental stewardship. Brands that prioritize sustainability resonate well with consumers who are becoming increasingly conscious of their purchasing decisions. By utilizing eco-friendly dyes, manufacturers not only appeal to a broader audience but also contribute to the overall reduction of pollution associated with traditional dyeing methods.

In conclusion, pre-reduced indigo dye represents a harmonious blend of tradition and innovation within the textile industry. By offering a sustainable alternative to conventional dyes, manufacturers can meet consumer demands for environmentally friendly products while preserving the rich cultural heritage of indigo dyeing. As the industry continues to evolve, the adoption of pre-reduced indigo dye is likely to play a significant role in shaping a more sustainable future for textile manufacturing.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.