setting indigo dye in fabric service

Setting Indigo Dye in Fabric A Step-by-Step Guide

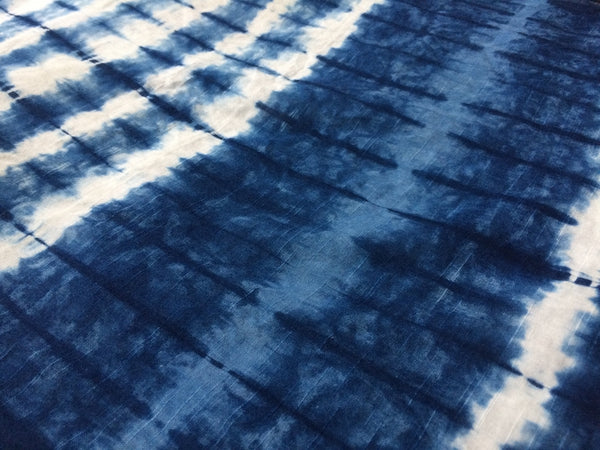

Indigo dyeing is a time-honored technique that brings a deep, rich blue hue to fabrics, transforming them into stunning pieces of art. Setting indigo dye in fabric involves a process that not only ensures vibrant colors but also enhances the fabric's durability and longevity. Here's a comprehensive guide on how to effectively set indigo dye in fabric.

Materials Needed

Before you begin, gather the necessary materials indigo dye, a fixer (typically sodium alginate or a commercial dye fixative), clean fabric (preferably natural fibers like cotton, linen, or silk), gloves, a mixing container, and a pot for steaming.

Step 1 Preparing the Fabric

First and foremost, prepare your fabric. It should be clean, free from any finishes, and pre-washed to remove any sizing agents. This step is crucial as it allows the dye to penetrate the fibers more effectively. After washing, rinse the fabric and let it dry completely.

Step 2 Dye Preparation

Next, prepare your indigo dye according to the instructions provided with the dye kit. Typically, this involves mixing the indigo powder with warm water and a reducing agent, such as sodium thiosulfate. Stir the mixture well until the dye dissolves completely, creating a rich blue solution.

setting indigo dye in fabric service

Step 3 Dyeing the Fabric

Once the dye is ready, immerse the fabric into the dye bath. This initial immersion will absorb the indigo, turning the fabric a light green hue. Gently agitate the fabric for even dye distribution. For deeper shades, repeat the immersion process, allowing the fabric to oxidize in between dips. The more you dip, the darker and richer the blue will become.

Step 4 Setting the Dye

To set the dye, it is essential to fix the color within the fabric fibers. You can do this by rinsing the dyed fabric in a mixture of warm water and your selected fixative. Following this, let the fabric rest for several hours, allowing the dye to bond securely with the fibers.

Step 5 Rinsing and Drying

After setting, rinse the fabric in cold water until the water runs clear. This step is vital as it removes any excess dye that hasn’t adhered to the fabric. Hang the fabric to dry in a shaded area to prevent sunlight from fading the colors.

Conclusion

Setting indigo dye in fabric is an intricate yet rewarding process. By following these steps, you can create beautiful, durable textiles that showcase the rich tradition of indigo dyeing. Embrace this art form, and enjoy the unique creations that emerge from your efforts!

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.