sulfer black manufacturer

The Emergence of Sulfur Black Manufacturers A Key Player in the Textile Industry

In the world of textiles, colorants play a crucial role in determining the visual appeal and overall quality of fabrics. Among various dyes, sulfur black is particularly favored for its deep, rich shades and excellent fastness properties. As environmental consciousness grows, the demand for high-quality sulfur black manufacturers has surged, leading to an evolution in the dyeing industry.

Understanding Sulfur Black Dyes

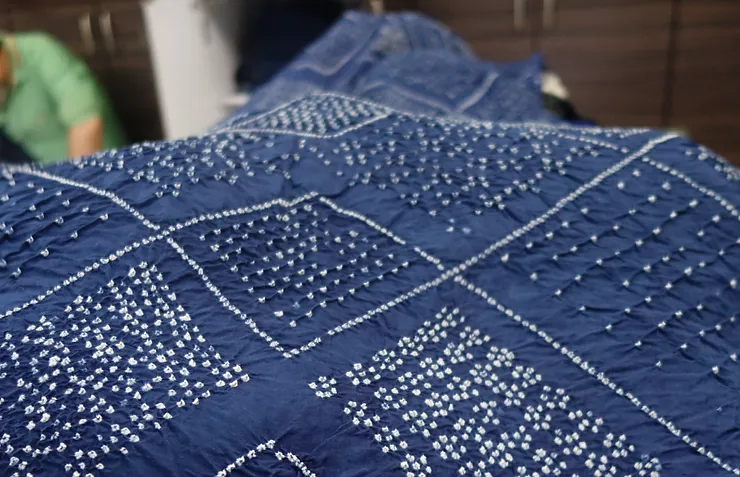

Sulfur black is a type of black dye that is primarily used in dyeing cotton and other cellulose fibers. It is known for its excellent color fastness to light and washing, making it a popular choice for denim and other textiles that undergo frequent washing and exposure to sunlight. The dye is produced through a chemical process involving sulfur compounds, which lends the dye its durability and depth of color.

The Growing Demand for Sulfur Black

The market for sulfur black is on the rise, driven by the increasing consumption of textile products worldwide. The global fashion industry has experienced remarkable growth, leading to a parallel surge in the demand for effective, durable dyes. Furthermore, consumers today are more discerning than ever; they expect high-quality textiles that maintain their appearance even after repeated washing. This demand creates opportunities for manufacturers who can provide superior sulfur black dyes.

Environmental Considerations

As the textile industry continues to expand, it faces mounting pressure to adopt environmentally sustainable practices. Traditional dyeing processes can be harmful to the environment, leading to water pollution and waste generation. However, leading sulfur black manufacturers have started to innovate and implement greener production methods. These include the use of less toxic raw materials, the recycling of water in dyeing processes, and the reduction of energy consumption. By adopting sustainable practices, manufacturers can minimize their environmental footprint while meeting the needs of eco-conscious consumers.

sulfer black manufacturer

Innovation in Manufacturing Processes

Modern sulfur black manufacturers are leveraging technology to improve their production processes. Automation and advanced machinery have enabled them to enhance efficiency and consistency in dye production. Additionally, research and development efforts have led to the creation of new formulations that provide improved performance characteristics, such as better solubility and reduced toxicity. These innovations not only meet industry standards but also align with the increasing demand for high-performance dyes that adhere to strict environmental regulations.

Global Competitive Landscape

The landscape for sulfur black manufacturers is highly competitive, with players from different parts of the world striving to capture market share. Major manufacturers have established their presence in Asia, Europe, and North America, each focusing on unique aspects of production and marketing. Asian manufacturers have been particularly aggressive, often offering cost-effective solutions that appeal to emerging markets. However, companies that prioritize quality, innovation, and sustainability are poised to stand out in this crowded marketplace.

Future Outlook

Looking ahead, the future of sulfur black manufacturing seems promising. The global textile industry is expected to continue growing, spurred by trends such as fast fashion, which requires quick turnaround times and steady supply chains. Moreover, the increasing focus on sustainability will push manufacturers to adopt more eco-friendly practices and develop new dye formulations that align with these values.

In conclusion, sulfur black manufacturers are essential players within the textile industry, contributing to the production of high-quality fabrics that meet consumer expectations. As the industry evolves, those who embrace innovation and sustainability will thrive in a competitive environment. With their ability to match the trends and demands of modern consumers, sulfur black manufacturers are set to play a pivotal role in shaping the future of textile dyeing.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.