sulfur dye factory

The Role of Sulfur Dye Factories in the Textile Industry

Sulfur dyes have carved a niche for themselves in the textile industry due to their exceptional properties, affordability, and versatility

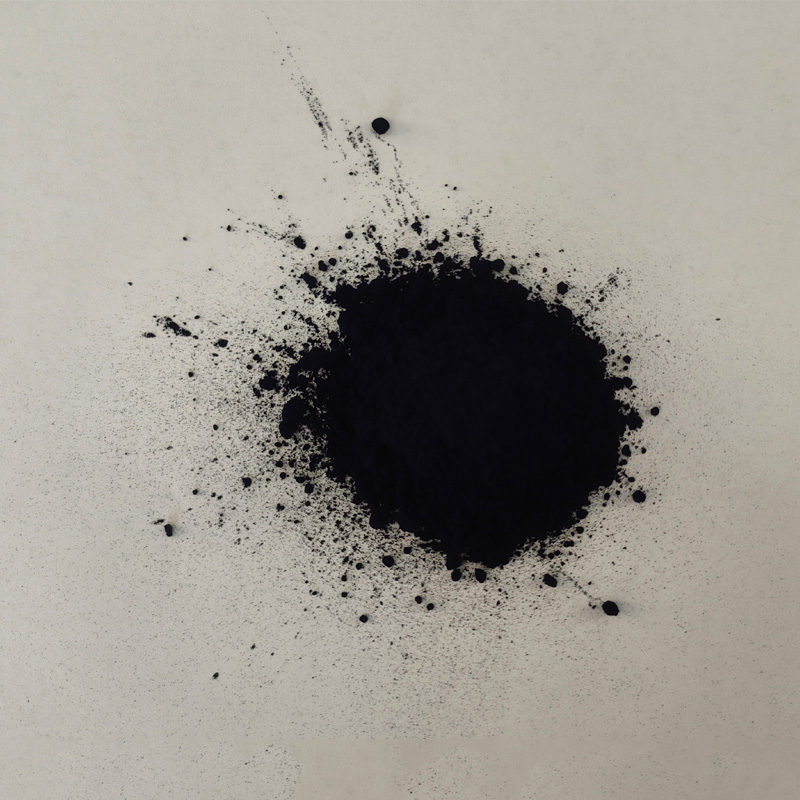

. A sulfur dye factory plays a crucial role in producing these dyes, which are primarily used to color cotton, wool, and other fibers, making them an indispensable part of the textile supply chain.The manufacturing process in a sulfur dye factory involves several steps, starting from the selection of raw materials. Sulfur dyes are derived from the reaction of sulfur with various organic compounds, resulting in a range of colors and shades. The factory utilizes advanced chemical processes to ensure that the dyes are produced efficiently and meet the required quality standards. The dyes are crafted in powder form, allowing them to be easily transported and utilized by textile manufacturers worldwide.

One of the significant advantages of sulfur dyes produced in these factories is their remarkable fastness properties. Unlike many other dye types, sulfur dyes are known for their excellent resistance to wash, light, and rubbing. This quality makes them particularly suitable for dyeing workwear, denim, and other fabrics that require durability. Furthermore, sulfur dyes are less expensive compared to other dye types, making them an attractive option for manufacturers looking to balance quality and cost.

sulfur dye factory

Environmental considerations are also a growing concern in the dyeing industry. Modern sulfur dye factories are increasingly adopting eco-friendly practices to minimize their environmental impact. Many are implementing wastewater treatment processes and using sustainable raw materials. Innovations such as closed-loop water systems and improved chemical formulations are being explored to reduce harmful byproducts and emissions associated with sulfur dye production.

Despite their advantages, sulfur dyes do have some limitations, such as the need for specific dyeing techniques and the potential for color variation. However, dedicated research and development within sulfur dye factories are addressing these challenges, leading to the creation of more advanced formulations that expand the range of applications for these dyes.

In conclusion, sulfur dye factories are vital to the textile industry, providing affordable, durable, and environmentally conscious dye solutions. As the industry continues to evolve, these factories will play an increasingly important role in meeting the demands of manufacturers and consumers alike, ensuring that the vibrant colors of textiles remain at the forefront of fashion and utility.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.