Factories Producing Sulfur-Free Black Powder for Cleaner Energy Solutions

The Rise of Sulfur-Free Black Powder Factories

In the world of pyrotechnics, firearms, and historical reenactments, the production of black powder—also known as gunpowder—has evolved remarkably over the years. Traditionally, black powder consisted of three main ingredients potassium nitrate (saltpeter), charcoal, and sulfur. However, increasing environmental regulations and safety concerns have prompted a significant shift toward sulfur-free formulations. This article explores the emergence of sulfur-free black powder factories, their benefits, and the future of pyrotechnic manufacturing.

The Need for Change

Historically, sulfur was a critical component in black powder, aiding in the rapid combustion and improving the overall efficiency of the explosive. However, sulfur brings with it several downsides. The production of sulfur generates noxious fumes and can contribute to environmental pollution. Furthermore, when black powder is ignited, sulfur combustion produces toxic gases, which pose health risks to manufacturers and users alike. In recent years, there has been a growing awareness of these risks, leading to a demand for cleaner and safer alternatives.

Sulfur-Free Black Powder Formulations

In response to this evolving landscape, many black powder manufacturers have begun exploring sulfur-free formulations. These alternatives typically rely on modified charcoal and potassium nitrate blends, often incorporating other binding agents that facilitate ignition and combustion. Innovations have led to the development of formulations that maintain performance while significantly reducing harmful emissions.

Some of the promising alternatives include the use of biochar, a sustainable product derived from organic materials, which not only provides the necessary combustible material but also contributes positively to the environment. The integration of various additives allows for custom formulations that can meet specific performance requirements without the drawbacks associated with sulfur.

Advantages of Sulfur-Free Production

sulfur free black powder factories

The transition to sulfur-free black powder production comes with numerous advantages. First and foremost is the reduction of environmental impact. By eliminating sulfur from the formulation, factories can significantly decrease their carbon footprint and comply with stricter environmental regulations. This enhances the sustainability of the industry and aligns it with global efforts to combat climate change.

Moreover, sulfur-free black powder contributes to safety—both for workers in manufacturing facilities and for consumers. With the absence of hazardous gases produced during combustion, the health risks associated with handling and using black powder are markedly reduced. This safety enhancement can lead to broader acceptance and use of black powder products in recreational shooting, historical reenactments, and even in professional applications like film and theater.

Challenges Ahead

Despite these advantages, transitioning fully to sulfur-free production is not without its challenges. Research and development in this area require significant investment, and many factories may be hesitant to shift from century-old traditions that have been deemed effective. Additionally, the manufacturing of sulfur-free black powder may involve more complex processes that could result in higher production costs, at least in the initial phases.

Furthermore, consumer acceptance plays a crucial role. Traditionalists within the black powder community may be skeptical of new formulations, fearing that performance may be compromised. Overcoming this skepticism will require thorough testing and demonstrations to prove that sulfur-free products can meet or even surpass the performance of their traditional counterparts.

The Future of Sulfur-Free Black Powder Factories

As the landscape of black powder production continues to evolve, the emergence of sulfur-free factories signifies a significant leap toward a safer and more environmentally friendly industry. Supported by advances in chemistry and material science, the future holds promise for innovative formulations that will not only preserve the heritage of black powder but also ensure its relevance in an eco-conscious world.

In conclusion, the emergence of sulfur-free black powder factories presents an opportunity to reinvent an age-old craft for the modern era. With an emphasis on sustainability, safety, and performance, this shift will likely shape the future of pyrotechnics, offering a cleaner and safer alternative that honors the tradition while prioritizing the health of both people and the planet. As consumer demand grows for safer and more sustainable options, the industry stands on the cusp of a significant transformation that could redefine black powder production for generations to come.

-

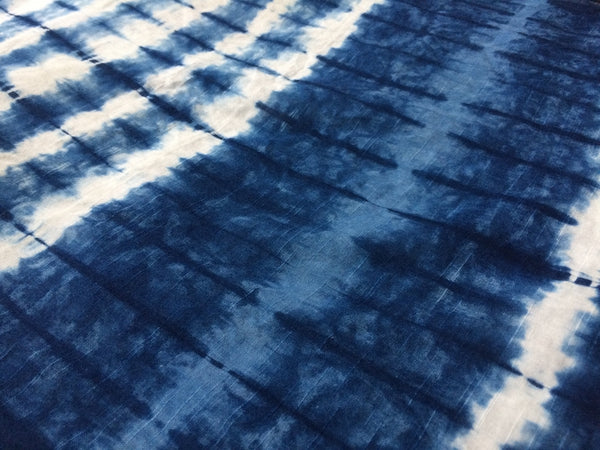

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.