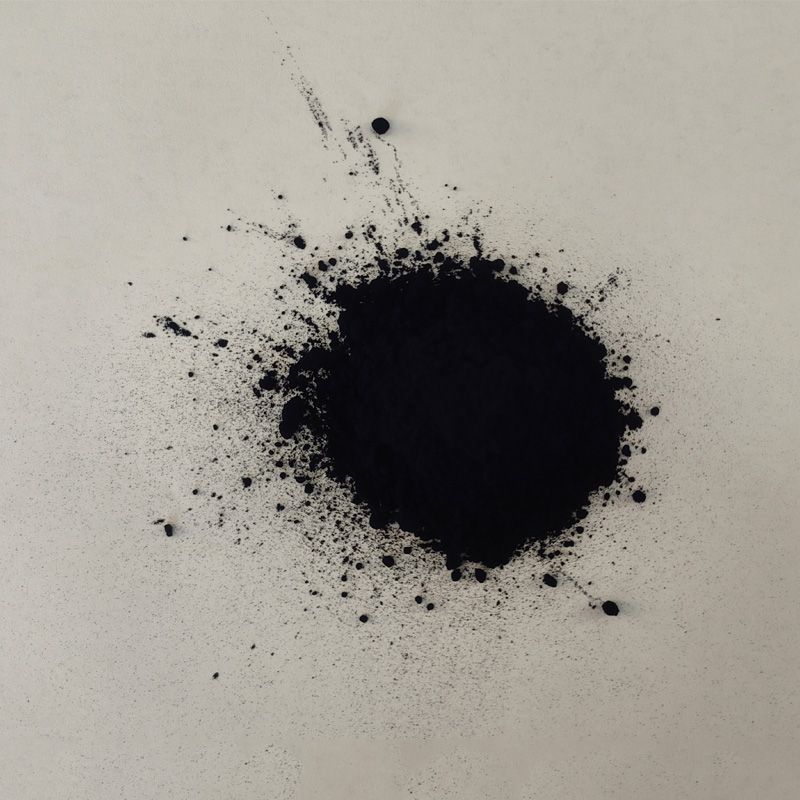

sulfur free black powder factory

The Importance of Sulfur-Free Black Powder Factories

In the world of manufacturing, particularly for explosives and propellants, the production process of black powder has undergone significant advancements. One of the most notable trends in this industry is the shift towards sulfur-free black powder. This innovation not only enhances the safety and effectiveness of the product but also addresses environmental concerns associated with traditional black powder production.

Understanding Black Powder

Black powder, also known as gunpowder, has been used for centuries in various applications, including firearms, fireworks, and mining. Traditionally, it is composed of three primary components potassium nitrate (saltpeter), charcoal, and sulfur. While sulfur serves to lower the ignition temperature and increases the speed of combustion, its presence also contributes to the creation of harmful gases and residues, which can be detrimental to both the environment and the health of workers in manufacturing facilities.

The Shift to Sulfur-Free Formulations

The development of sulfur-free black powder formulations marks a significant milestone in the industry. This alternative composition typically replaces sulfur with other oxidizers or fuels that retain, and often improve, the performance characteristics of the powder. By eliminating sulfur, manufacturers can produce a cleaner-burning product that results in fewer toxic byproducts during combustion.

This transition not only enhances the safety profile of the black powder but also mitigates the risks associated with handling and storing traditional formulations. Factories producing sulfur-free black powder can boast lower emissions, reducing their environmental footprint. This aspect is becoming increasingly appealing to both consumers and regulatory bodies that prioritize environmentally sustainable practices in manufacturing.

Benefits of Sulfur-Free Black Powder

1. Improved Stability and Safety Sulfur-free black powder tends to have a more stable chemical profile, reducing the risk of accidental detonation during storage and handling. This provides an additional layer of safety for manufacturers and users alike.

sulfur free black powder factory

2. Reduced Toxic Emissions By producing a cleaner-burning product, sulfur-free black powder eliminates the release of toxic gases such as sulfur dioxide and other harmful compounds. This not only protects the environment but also improves air quality in the vicinity of manufacturing plants.

3. Enhanced Performance Often, sulfur-free formulations can achieve similar or even superior ballistic performance compared to their traditional counterparts. This means that manufacturers do not need to sacrifice effectiveness for safety or environmental concerns.

4. Regulatory Compliance As governments worldwide tighten regulations on hazardous materials, moving towards sulfur-free production can help companies stay ahead of compliance requirements, avoiding potential fines and negative publicity associated with environmental infractions.

5. Market Demand The growing trend for eco-friendly products among consumers creates a robust market for sulfur-free black powder. Many industries, including sports shooting and fireworks, are increasingly seeking out greener alternatives, presenting manufacturers with new opportunities for growth.

The Role of Innovation in Manufacturing

The transition to sulfur-free black powder is made possible through ongoing research and development efforts within the industry. Companies are investing in state-of-the-art technology and innovative practices to refine their production processes, ensuring that they can deliver high-quality products without compromising safety or environmental standards.

Moreover, collaboration between scientists, manufacturers, and regulatory agencies plays a critical role in the advancement of sulfur-free formulations. By sharing knowledge and resources, stakeholders can continuously improve product quality while addressing environmental concerns.

Conclusion

In conclusion, the emergence of sulfur-free black powder factories symbolizes a forward-thinking approach in the explosives manufacturing industry. This shift not only aligns with global trends towards sustainability but also emphasizes the importance of safety and performance. As the world becomes increasingly aware of the need for environmentally responsible practices, sulfur-free black powder stands out as a prime example of how innovation can drive positive change. Manufacturers that embrace this evolution are likely to thrive in an ever-competitive market, paving the way for a cleaner and safer future in the production of explosives and propellants.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.