sulfur free black powder manufacturers

An Overview of Sulfur-Free Black Powder Manufacturers

In the world of pyrotechnics and ammunition, black powder has long been a staple due to its explosive properties and ease of use. Traditionally, black powder contains three primary ingredients potassium nitrate (saltpeter), charcoal, and sulfur. However, the inclusion of sulfur has raised concerns regarding toxicity, residue, and performance inconsistencies, leading to a growing interest in sulfur-free black powder. In response to this demand, numerous manufacturers are now focusing on sulfur-free formulations to meet the needs of various industries including firearms, fireworks, and other applications.

The Need for Sulfur-Free Black Powder

The removal of sulfur from black powder presents several advantages. Sulfur, while it contributes to the powder's combustibility, also produces significant amounts of residue that can affect performance and cleanliness. In firearm applications, excess residue can lead to fouling in the barrel, reducing accuracy and increasing maintenance needs. For fireworks, sulfur can alter the color and brightness of the displays, which might not be desirable for certain applications. Therefore, manufacturers are investing in the development of sulfur-free formulas that maintain explosive performance while minimizing these undesired effects.

The Role of Manufacturers

Numerous manufacturers around the globe are dedicated to producing sulfur-free black powder. These companies focus on researching alternative formulations that can produce energy comparable to traditional black powder while ensuring cleaner combustion. By replacing sulfur with suitable substitutes, manufacturers aim to maintain the effectiveness of the powder in applications ranging from shooting sports to pyrotechnic displays.

sulfur free black powder manufacturers

Some notable strategies that these manufacturers employ include enhancing the granulation process and improving the quality of the reactive components. The fine-tuning of raw materials and precise mixing techniques allows for a higher level of control over the burn rate and energy output of the powder.

Innovative Approaches

Among the innovative approaches taken by sulfur-free black powder manufacturers is the use of advanced chemical engineering technologies to create a balanced, effective product. By adjusting the ratios of potassium nitrate and charcoal and experimenting with various carbon sources, manufacturers can create formulations that deliver superior performance without the presence of sulfur. Additionally, research into binders and stabilizers helps improve moisture resistance and shelf-life, making sulfur-free black powder a more reliable choice for consumers.

Market Growth and Future Prospects

The market for sulfur-free black powder is witnessing growth, fueled by increased consumer awareness regarding health and environmental implications. As outdoor recreation and shooting sports gain popularity, more enthusiasts are seeking cleaner, safer alternatives. Manufacturers are keenly aware of these trends and are committed to advancing their products to cater to this growing demographic.

In conclusion, sulfur-free black powder manufacturers play a crucial role in the evolution of pyrotechnics and ammunition. By focusing on innovative materials and methods, these companies provide safer, cleaner, and more efficient alternatives to traditional black powder. As the demand for sustainable and environmentally friendly options continues to rise, the future of sulfur-free black powder looks promising. With ongoing research and development, manufacturers are well-positioned to lead the charge in creating high-performing, sulfur-free products that meet the needs of diverse markets.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

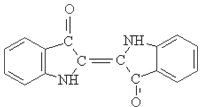

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.