sulphur dyeing pricelist

An Overview of Sulphur Dyeing Prices Factors Influencing Costs

Sulphur dyeing is an essential process in the textile industry, known for its ability to produce deep, rich colors on cotton and other natural fibers. The use of sulphur dyes has grown in popularity due to their excellent lightfastness and washfastness, making them a preferred choice for various applications. However, like many processes in manufacturing, the cost of sulphur dyeing can vary considerably. Understanding these pricing dynamics is crucial for manufacturers, designers, and retailers alike.

Factors Influencing Sulphur Dyeing Prices

1. Raw Materials The primary component of sulphur dyeing is, of course, the dyes themselves. The cost of sulphur dyes can fluctuate depending on the availability of raw materials used in their production. Prices for these dyes might increase due to supply chain disruptions, changes in demand, or advancements in dyeing technologies.

An Overview of Sulphur Dyeing Prices Factors Influencing Costs

3. Labor Costs The skill and availability of labor can have a significant impact on dyeing costs. Locations with higher labor costs will naturally increase the overall price of sulphur dyeing services. Conversely, regions with lower labor costs might offer more competitive pricing, but this can sometimes lead to variability in quality.

sulphur dyeing pricelist

4. Volume and Scale The order volume also plays a critical role in pricing. Larger orders may benefit from economies of scale, resulting in lower per-unit costs. On the other hand, small-batch dyeing could be more expensive due to fixed costs that are distributed over fewer items.

5. Market Trends The global textile market is influenced by trends that can shift quickly, affecting dye demand and, subsequently, the prices. For example, a surge in fast fashion trends may result in higher demand for sulphur dyes, leading to price hikes in response to increased competition among producers.

6. Supplier Relationships Long-standing relationships between dyeing factories and their suppliers can also play a role in pricing. Established connections may lead to better negotiations and discounts on raw materials, benefitting the final cost of dyeing.

Conclusion

Understanding the pricing structure of sulphur dyeing is vital for any textile enterprise aiming to manage costs effectively. By keeping abreast of the various factors that influence these prices, manufacturers can make informed decisions, ensuring quality and competitiveness in a rapidly evolving market. Whether it’s choosing a supplier, opting for a specific dyeing process, or negotiating bulk purchasing agreements, knowledge of sulphur dyeing pricing can be a significant advantage.

-

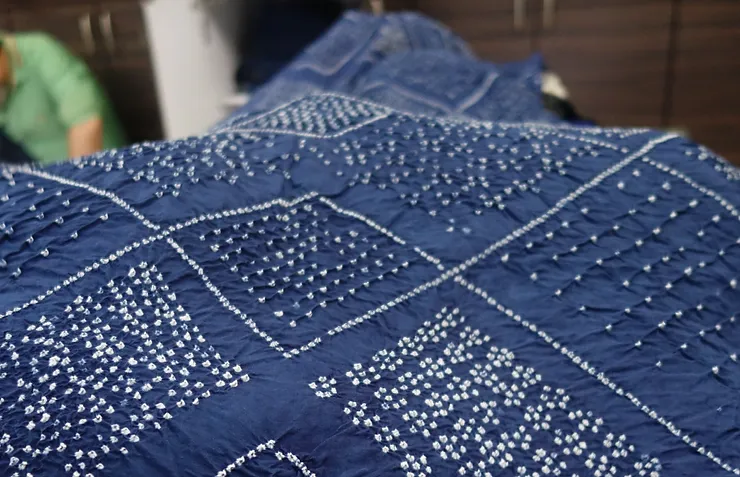

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.