sulphur dyeing service

The Rise of Sulphur Dyeing Services in the Textile Industry

In recent years, the textile industry has witnessed a significant transformation driven by innovations in dyeing techniques and the growing demand for sustainable practices. Among these developments, sulphur dyeing has emerged as a popular choice, offering numerous advantages in terms of cost-efficiency, color vibrancy, and environmental sustainability. This article explores the importance of sulphur dyeing services, their benefits, and their role in the evolving textile landscape.

Sulphur dyes are a class of synthetic dyes characterized by their sulfur-containing compounds. They provide a wide range of colors and are particularly favored for their deep hues and excellent lightfastness. Traditional dyeing methods often require extensive processing times and substantial amounts of water, but sulphur dyeing significantly reduces these requirements due to its unique chemical properties. By utilizing this dyeing process, textile manufacturers can achieve vibrant colors while minimizing water consumption and energy usage.

One of the key benefits of sulphur dyeing is its cost-effectiveness. The dyeing process is relatively simple and can be executed at lower temperatures compared to other dyeing methods. This reduces both energy costs and the overall time required for the dyeing process. As businesses strive to become more competitive, the affordability of sulphur dyeing makes it an attractive option for manufacturers looking to optimize their production processes without sacrificing quality.

In addition to cost savings, sulphur dyeing services are becoming increasingly important in the context of sustainability. The growing awareness of environmental issues requires the textile industry to adopt greener practices, and sulphur dyes are known for their reduced environmental impact. When compared to conventional dyes, sulphur dyes generally use less water during the application process and do not require harmful chemical additives. This results in less wastewater being generated, which is crucial for protecting water resources and maintaining ecological balance.

sulphur dyeing service

Moreover, advancements in sulphur dye formulations have led to the development of non-toxic and biodegradable alternatives, further enhancing their appeal to environmentally-conscious brands. These innovations will likely play a significant role in the industry's shift toward sustainable dyeing practices, aligning with consumer demand for eco-friendly products.

In terms of practicality, sulphur dyeing services can cater to various textile materials, including cotton, polyester, and blends. This versatility makes sulphur dyeing suitable for a wide range of applications—from fashion textiles to industrial fabrics. The rich color range offered by sulphur dyes allows manufacturers to fulfill diverse customer preferences and trends, ensuring that they stay ahead in a competitive market.

Furthermore, the adaptability of sulphur dyeing services has made them an attractive option for small and large textile producers alike. As customization becomes increasingly important in the fashion and textile sectors, sulphur dyeing enables manufacturers to experiment with different shades and patterns, catering to niche markets while still adhering to sustainability standards.

However, it is essential to recognize that the success of sulphur dyeing services relies on skilled personnel and modern equipment. High-quality results demand expertise in dye application techniques and an understanding of the specific chemical properties of sulphur dyes. Therefore, investing in training and the latest technology is crucial for businesses looking to leverage sulphur dyeing effectively.

In conclusion, sulphur dyeing services are rapidly gaining traction in the textile industry, driven by their cost-effectiveness, sustainability, and versatility. As manufacturers and consumers alike continue to prioritize eco-friendly practices, sulphur dyes offer a viable solution that meets these demands while ensuring high-quality output. By incorporating sulphur dyeing into their operations, textile businesses can not only improve their overall efficiency but also contribute to a more sustainable future for the industry as a whole. The ongoing evolution of dyeing technologies will undoubtedly solidify sulphur dyeing’s position as a cornerstone in modern textile production.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

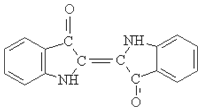

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.