Sustainable Indigo Dyeing Techniques for Modern Jean Manufacturing A Closer Look at Factories

The Indigo Dye Jeans Factory Tradition Meets Modernity

In the heart of the textile industry, the indigo dye jeans factory stands as both a beacon of tradition and a testament to modern manufacturing. Indigo dyeing, one of the oldest dyeing techniques known to humankind, has found a new home in contemporary fashion, particularly in the ever-popular denim jeans. This article explores the intricate world of an indigo dye jeans factory, where craftsmanship and technology intertwine.

The Legacy of Indigo Dyeing

Indigo dyeing dates back thousands of years, with evidence of its use found in ancient civilizations across different continents, from Egypt to Japan. The deep blue hue of indigo is derived from the leaves of the indigo plant, primarily Indigofera tinctoria. This natural dyeing process is labor-intensive, requiring skill and patience. Traditionally, artisans would ferment the leaves to create a dye solution, a process that transforms the bright green leaves into the striking blue pigment that captures the imagination.

In the context of jeans production, the indigo dye serves multiple purposes. It not only imbues the fabric with its characteristic color but also ages beautifully over time, allowing for unique fade patterns that many consumers seek in their denim. The love for vintage jeans, with their subtly worn yet stylish appearance, has driven the demand for high-quality indigo dye jeans, creating a revival of interests in traditional dyeing methods.

Modern Production Techniques

In a modern indigo dye jeans factory, the melding of traditional techniques with cutting-edge technology is evident. While some artisans still utilize centuries-old dyeing processes, advanced machinery and innovative practices enhance efficiency and sustainability. Factories now employ both synthetic and natural indigo, balancing tradition with the economic benefits of speed and affordability.

indigo dye jeans factory

The dyeing process itself has evolved, incorporating eco-friendly practices to minimize water usage and reduce environmental impact. Many factories are adopting closed-loop systems that recycle water and reduce waste, reflecting a growing commitment to sustainable fashion. This shift not only benefits the planet but also appeals to conscious consumers who prioritize sustainability in their purchasing decisions.

The Art of Craftsmanship

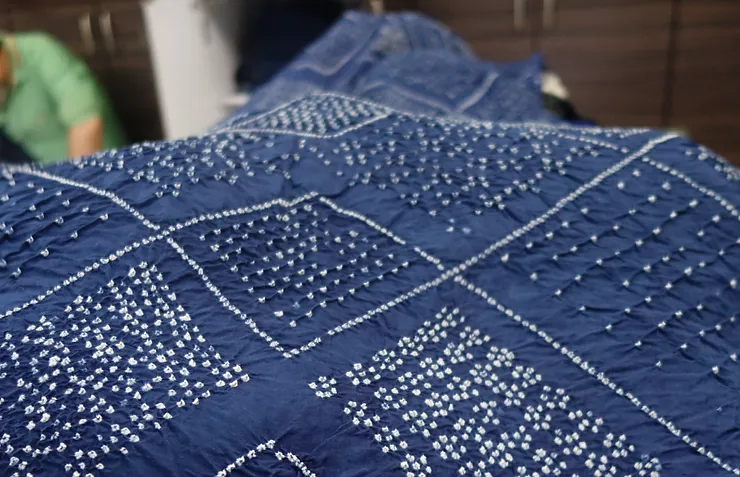

At the heart of the indigo dye jeans factory is the dedication to craftsmanship. Skilled artisans take pride in their work, ensuring that each pair of jeans meets high quality and aesthetic standards. From selecting the right denim fabric to the precise application of indigo dye, every step is an expression of artistry. The detail involved in creating fades, stitching, and washes elevates denim from mere clothing to a fashion statement.

Moreover, the rise of bespoke and custom denim has transformed consumer expectations. Factories are increasingly offering bespoke services, where customers can choose everything from the type of denim to the specific shade of indigo. This personal touch not only enhances customer satisfaction but also deepens the connection between the wearer and the craftsmanship behind their jeans.

A Bright Future

As fashion trends come and go, the indigo dye jeans factory continues to maintain its relevance. The interplay of tradition and innovation ensures that indigo dyeing remains a respected practice while meeting contemporary demands. With increased awareness surrounding sustainable practices and the growing appreciation for artisanal craftsmanship, the future of indigo dye jeans appears bright.

In conclusion, the indigo dye jeans factory represents much more than just a place of production; it is a fusion of history, artistry, and modernity. As consumers increasingly seek meaningful connections with their clothing, the indigo dye jeans factory stands poised to deliver not just stylish jeans but a story of rich heritage and commitment to sustainable innovation. Whether you are a denim aficionado or a casual wearer, there is something undeniably captivating about a pair of jeans that carries the legacy of indigo dyeing.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.