Premium Synthetic Indigo Powder Manufacturers | High-Quality Colorants

The Rise of Synthetic Indigo Powder Manufacturers

In recent years, the textile industry has undergone significant changes, with a marked shift toward synthetic dyes due to their versatility and cost-effectiveness. Among these synthetic dyes, indigo powder has gained notable attention. Traditionally derived from natural sources, indigo has long been valued for its rich blue hue, commonly used in dyeing denim and other fabrics. However, with the demand for consistent quality and sustainable production practices, synthetic indigo powder manufacturers have risen to prominence.

Synthetic indigo powder is produced through a chemical process that replicates the natural indigo compound. This method offers several advantages over traditional natural indigo. First, synthetic processes allow for greater control over the dye’s consistency and quality, ensuring that manufacturers can deliver products that meet the rigorous standards of modern textile production. Furthermore, synthetic production can be scaled more efficiently, ensuring supply meets the increasing demands of the marketplace.

One of the primary reasons for the surge in synthetic indigo usage is the growing awareness of environmental issues associated with traditional indigo farming. The cultivation of indigo plants often requires extensive agricultural practices, including the use of pesticides, which can lead to soil depletion and water pollution. Furthermore, the farming process can be labor-intensive and time-consuming. In contrast, synthetic indigo production presents a more environmentally friendly alternative, as it generally requires fewer natural resources and can minimize the ecological impact.

Moreover, advancements in synthetic dye technology have allowed manufacturers to create indigo in a way that is not only environmentally sustainable but also economically viable. For instance, companies are now using less harmful chemicals and adopting greener production methods, such as using renewable energy sources. This shift not only satisfies consumer demand for sustainable products but also aligns with global initiatives aimed at reducing the carbon footprint of the textile industry.

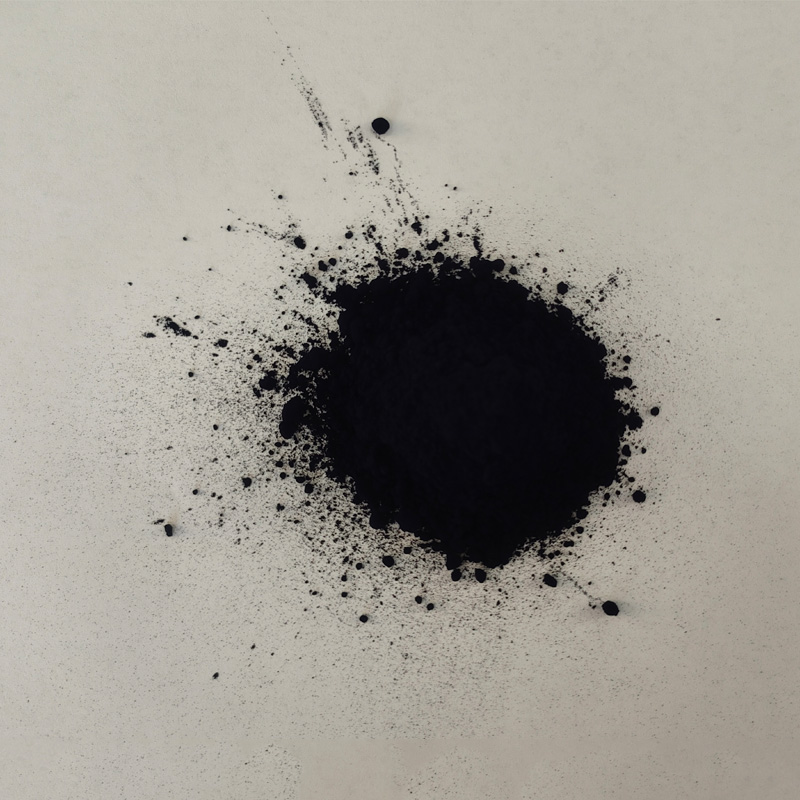

synthetic indigo powder manufacturers

The increase in synthetic indigo powder manufacturers has also led to competitive pricing and innovation in dyeing techniques

. With multiple suppliers entering the market, textile producers can source high-quality indigo at more affordable rates. This competition encourages continuous improvement in product quality and customer service, fostering partnerships that further drive the industry forward.In the face of rising environmental concerns and a growing population, the future of synthetic indigo powder looks bright. With ongoing research and development, manufacturers are exploring new methods to enhance the dyeing process, improving colorfastness and other dye characteristics. This innovation could lead to even broader applications beyond textiles, including use in paints, inks, and plastics.

Additionally, as consumers become more conscious of the environmental impact of their purchases, the demand for ethically produced synthetic indigo is likely to rise. Manufacturers who invest in sustainable practices and transparency in their production processes will be well-positioned to meet this demand.

In conclusion, the emergence of synthetic indigo powder manufacturers marks a significant evolution in the textile industry. By prioritizing sustainability and innovation, these manufacturers not only cater to market demands but also contribute to the preservation of our planet. As the industry continues to adapt, synthetic indigo powder is poised to play an essential role in shaping a more sustainable future for textiles and beyond.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.