Leading Supplier of Synthetic Indigo Dye for Global Markets and Exports

The Synthetic Indigo Dye Exporter A Key Player in the Global Textile Market

Synthetic indigo dye, widely recognized for its deep blue hue, has become an essential component in the textile industry, particularly for denim production. The synthetic version, developed in the late 19th century, has largely replaced natural indigo, not only due to its cost-effectiveness but also because of its consistent quality and ease of production. As the global demand for indigo-dyed textiles continues to rise, synthetic indigo dye exporters play a crucial role in meeting this demand while navigating the complexities of international trade.

Understanding Synthetic Indigo

Synthetic indigo is chemically manufactured through various processes, primarily from aniline or its derivatives. This method produces dye that exhibits similar properties to natural indigo, such as its solubility in alkaline solutions and its ability to create vibrant colors on fabric. The production of synthetic indigo is more efficient and less labor-intensive than harvesting natural indigo plants, which require significant agricultural input and time to cultivate.

Market Dynamics

The global textile market for synthetic indigo is heavily influenced by the booming demand for denim apparel. As the fashion industry evolves, denim remains a staple in wardrobes worldwide. The rise of fast fashion has further fueled the demand for high volumes of indigo-dyed fabrics, prompting textile manufacturers to seek reliable synthetic indigo suppliers.

Exporters often face challenges in this competitive landscape. They must ensure a consistent supply of high-quality dye while adhering to environmental regulations and sustainability initiatives. Moreover, fluctuations in raw material prices and international trade policies can impact their operations and profitability. To mitigate these risks, many exporters invest in research and development to optimize production processes and reduce environmental impacts.

Key Players in Synthetic Indigo Exportation

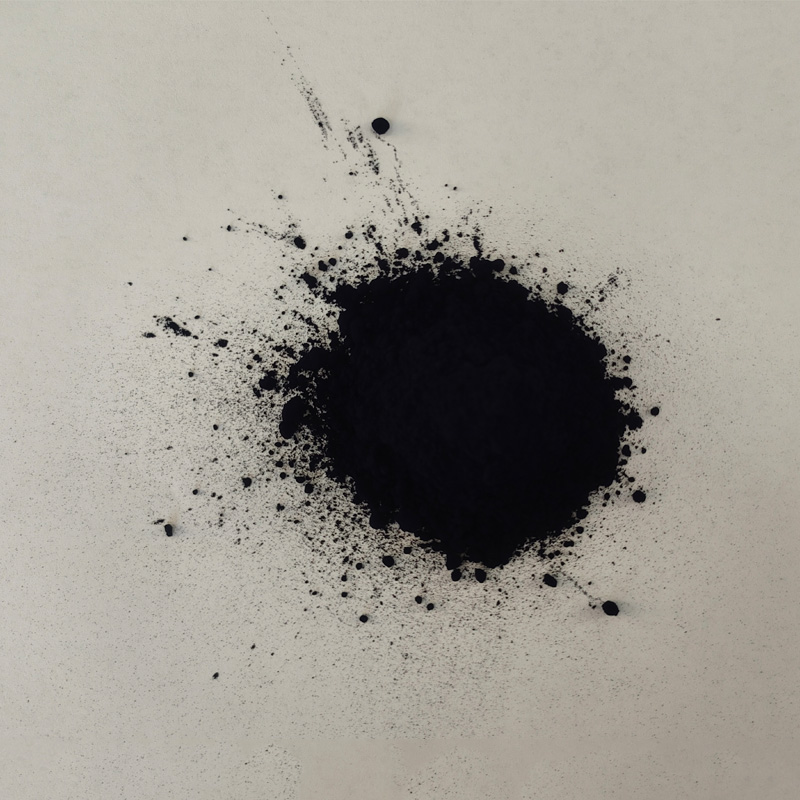

synthetic indigo dye exporter

The synthetic indigo market is characterized by a mix of established chemical companies and small to medium-sized enterprises (SMEs). Major players like Takeda Chemical Industries, Bayer AG, and Dystar have a significant share of the market, leveraging their extensive distribution networks and established relationships with global textile manufacturers. These companies often engage in strategic collaborations and investment in innovative technologies to enhance their product offerings.

Furthermore, emerging markets in Asia, particularly India and China, have seen a surge in synthetic indigo production to cater to the local and international markets. India's flourishing textile industry, combined with a focus on sustainable practices, positions the country as a key exporter of synthetic indigo. Government initiatives promoting quality standards and manufacturing efficiency further bolster its competitiveness.

Environmental Considerations

As the synthetic indigo industry grows, environmental concerns associated with chemical production processes have gained prominence. Exporters are increasingly held accountable for their carbon footprints and the sustainability of their operations. Many companies are now adopting greener practices, such as utilizing water-efficient production techniques and exploring alternative, eco-friendly raw materials.

Additionally, various international certifications and compliance standards have emerged, encouraging exporters to maintain sustainable practices throughout their supply chains. This focus not only meets regulatory requirements but also caters to an increasingly eco-conscious consumer base that values sustainability in production.

Conclusion

The role of synthetic indigo dye exporters is essential in a global textile market that continues to evolve. With the increasing demand for denim and other indigo-dyed products, these exporters face both challenges and opportunities. By emphasizing quality, sustainability, and innovation, they can navigate the complexities of international trade while contributing to a thriving industry. The future looks promising for synthetic indigo, and as the market grows, so does the importance of its key players in shaping the future of textile dyeing.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.