synthetic indigo dye manufacturers

The Evolution and Impact of Synthetic Indigo Dye Manufacturers

Synthetic indigo dye, a vibrant and popular colorant, has revolutionized the textile industry since its inception. Traditionally derived from the indigo plant, the manufacturing of synthetic indigo represents a significant advancement in dye technology, enabling mass production and consistent color quality. This article will explore the history, processes, and implications of synthetic indigo dye manufacturing, along with its impact on the global textile market.

Historical Context

Indigo dyeing has a long and storied history, tracing back thousands of years to ancient civilizations in regions such as Egypt, India, and South America. The natural dye was highly prized for its deep blue hue, often used in textiles for royalty and the elite. However, the labor-intensive harvesting process of indigo plants limited availability and accessibility. In the late 19th century, chemists began to explore synthetic alternatives to meet growing demand, leading to the first successful synthesis of indigo in 1897 by Adolf von Baeyer, which would pave the way for modern production techniques.

The Synthetic Production Process

The manufacturing of synthetic indigo typically employs two major chemical processes the vat and the reductive processes. Initially, anilines, derived from benzene, undergo nitration to create nitroanilines, which are then reduced to aniline. Subsequently, these compounds undergo a series of reactions to form indigo through a chemical process called condensation. Once synthesized, indigo can be further processed into a powder or paste for dyeing fabrics.

The production of synthetic indigo has heavily benefitted from advancements in technology. Automation and improved chemical engineering have led to higher efficiency and lower production costs. Modern manufacturers can produce large quantities of indigo dye with consistency, helping to stabilize market prices and providing dyers with reliable sourcing.

Environmental Considerations

synthetic indigo dye manufacturers

As with any industrial process, synthetic indigo production raises significant environmental concerns. The chemicals involved in manufacturing can be hazardous, leading to potential pollution issues if waste management is not properly maintained. For instance, the use of aniline and its derivatives poses risks to both human health and ecosystems.

In response to these concerns, many manufacturers have adopted more environmentally friendly practices. This includes developing closed-loop systems that minimize waste and recycling wastewater, as well as investing in research for less harmful alternatives and more sustainable production methods. Moreover, regulations surrounding chemical manufacturing have become stricter, compelling companies to rethink their processes and prioritize greener practices.

Impact on the Textile Industry

The rise of synthetic indigo dye has dramatically altered the landscape of the textile industry. Its widespread adoption allows manufacturers to create a vast array of blue hues and patterns at a lower cost, making it an ideal choice for denim, especially in the production of jeans. The ability to achieve consistent color quality, paired with reduced dyeing times, has made synthetic indigo a staple in apparel manufacturing.

Additionally, the economic benefits of synthetic indigo have contributed to the expansion of the global denim market. As countries such as Bangladesh, China, and India emerged as leading denim producers, synthetic indigo manufacturing became an integral part of their economies. However, the dynamics of the market also highlight the need for ethical practices, especially regarding labor conditions and environmental stewardship.

Future Prospects

Looking forward, synthetic indigo dye manufacturers face challenges and opportunities in the evolving textile landscape. Rising consumer awareness and demand for sustainable products have prompted manufacturers to innovate continuously. The introduction of bio-based indigo and digital dyeing technologies represent potential avenues for growth, aligning production with environmental sustainability and consumer preferences.

In conclusion, synthetic indigo dye manufacturers have played a pivotal role in transforming the textile industry through their innovative approaches and scalable production methods. While challenges around environmental impact and ethical practices must be addressed, the future holds promise for continued advancements in sustainable dye manufacturing, ensuring that this vibrant color remains a staple in fashion for generations to come.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

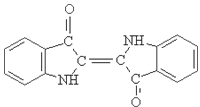

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.