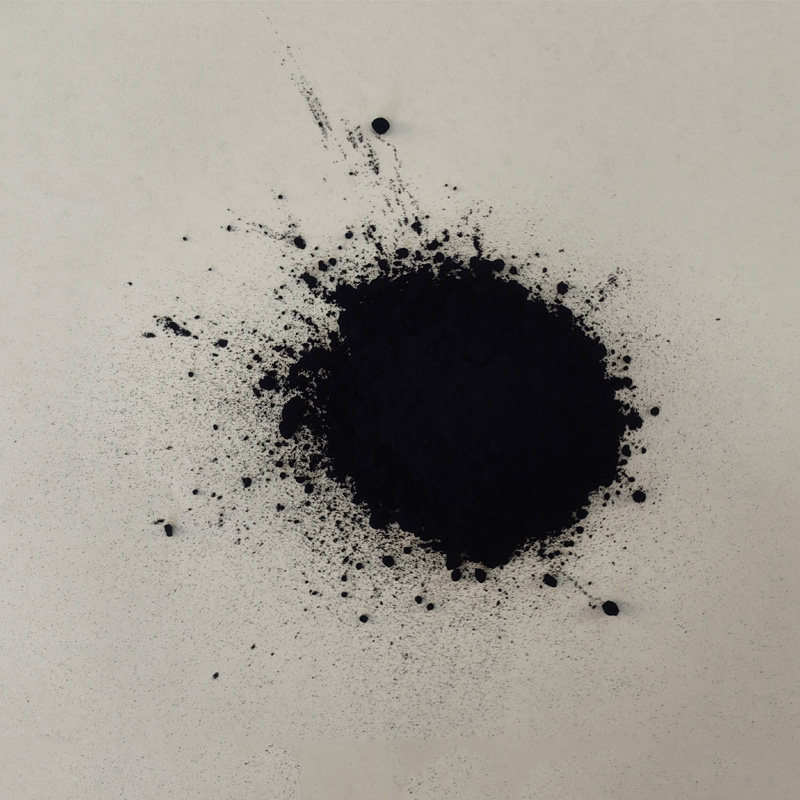

synthetic indigo powder factory

The Rise of Synthetic Indigo Powder Factories Revolutionizing the Textile Industry

For centuries, indigo dye has been cherished for its deep blue hues, making it a staple in the textile industry. Traditionally derived from natural sources, such as the Indigofera plant, the extraction and production processes were labor-intensive and often limited by geographic constraints. However, the increasing demand for indigo dye, driven by the fast fashion industry and innovative textile applications, has led to the emergence of synthetic indigo powder factories. These facilities not only meet the rising demand for indigo but also offer various advantages over traditional methods.

Synthetic indigo powder is created through chemical processes, primarily involving the oxidation of indoxyl, which is derived from aniline. The production of synthetic indigo allows for greater consistency in the dye's quality and color, alleviating the variability often associated with natural indigo. This consistency is crucial for manufacturers who need to meet strict quality standards and color specifications for their products.

The Rise of Synthetic Indigo Powder Factories Revolutionizing the Textile Industry

Moreover, the environmental impact of synthetic indigo powder production is often less detrimental compared to its natural counterpart. The farming of indigo plants generally requires large amounts of water, land, and pesticides, which can strain local ecosystems. In contrast, modern synthetic production methods can be designed to minimize waste and energy consumption. Many factories are adopting eco-friendly practices, such as recycling water used in the dyeing process and implementing renewable energy sources to power operations. These innovative approaches have led to a more sustainable dye production system, appealing to environmentally conscious consumers and brands.

synthetic indigo powder factory

Additionally, the scalability of synthetic indigo powder production is a significant benefit for the textile industry. With the rise of fast fashion, brands are frequently looking to increase their output to keep up with trends. Synthetic indigo factories can quickly scale operations to meet fluctuating market demands, ensuring that manufacturers can promptly deliver their products to retailers. This adaptability not only enhances consumer satisfaction but also allows brands to experiment with new designs and applications, driving innovation in the textile sector.

The global indigo market is witnessing a shift as key players invest in synthetic dye production. Countries such as China, India, and the United States are at the forefront of this transition, establishing factories that produce high-quality synthetic indigo. These regions not only have the technological infrastructure necessary for such operations but also a highly skilled workforce capable of advancing the industry further.

However, the rise of synthetic indigo powder factories is not without its challenges. As the industry grows, ensuring the safety and health of workers in these facilities becomes a critical concern. The chemicals used in synthetic dye production can pose various health risks if not managed properly. Therefore, companies are increasingly focused on implementing stringent safety protocols and providing training for employees to mitigate risks associated with working in chemical environments.

In conclusion, synthetic indigo powder factories are revolutionizing the textile industry by providing a reliable, efficient, and sustainable source of dye. As demand continues to grow, the ability of synthetic production to meet quality standards, enhance sustainability, and scale efficiently will make it an indispensable part of the modern textile landscape. While challenges remain, the future of indigo dyeing is undoubtedly brighter with the advent of synthetic alternatives, paving the way for innovative applications and practices within the industry. The deep blue of indigo, now more accessible than ever, remains a testament to the blend of tradition and modern technology in textile production.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.