Manufacturers of Synthetic Indigo Powder for Textile and Dyeing Industries

The Evolution and Impact of Synthetic Indigo Powder Manufacturers

Synthetic indigo powder has emerged as a significant player in the textile industry, providing a sustainable and cost-effective alternative to natural indigo. The journey of synthetic indigo began in the late 19th century, and since then, manufacturers have innovated and refined the production processes, meeting the growing global demand for this vibrant dye.

Historical Background

Indigo dyeing has ancient roots, dating back thousands of years, where natural sources, such as the Indigofera plant, were primarily used. While natural indigo was cherished for its deep blue hue, it came with certain limitations, including higher costs and inconsistent availability. The industrial revolution catalyzed the search for synthetic alternatives, leading to the synthesis of indigo by German chemist Adolf von Baeyer in 1880. This landmark discovery paved the way for large-scale production and reshaped the textile industry.

The Manufacturing Process

The production of synthetic indigo powder typically involves several key chemical reactions and processes. The primary method used today is the oxidation of indigo precursors such as aniline and nitrobenzene in the presence of strong bases. Manufacturers have developed various methods to optimize yield and reduce environmental impact, including utilizing greener alternatives and recycling waste products.

In modern synthetic indigo powder manufacturing, quality control plays a vital role. Manufacturers implement strict testing protocols to ensure color consistency, solubility, and overall performance of the dye. This level of scrutiny is crucial, as cotton and denim industries demand high standards for their colorfast products.

The Role of Synthetic Indigo in Today’s Market

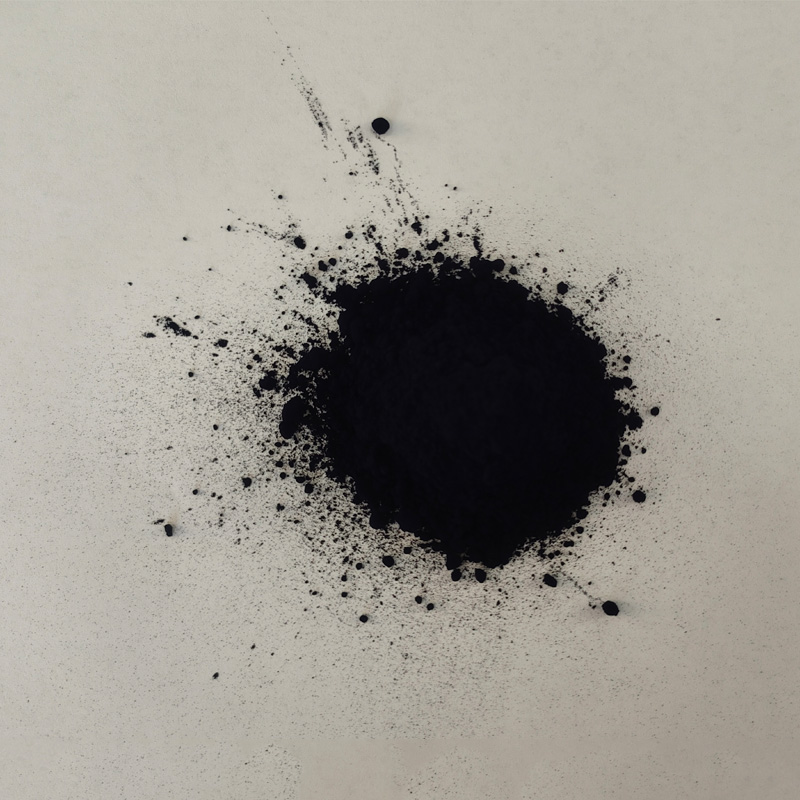

synthetic indigo powder manufacturers

As the fashion industry continues its shift toward sustainability, synthetic indigo powder has gained prominence. With the textile market's increasing awareness of environmental impacts, manufacturers have sought ways to provide eco-friendly options without compromising quality. Synthetic indigo is often favored because it allows for greater control over the dyeing process, resulting in fewer water resources being wasted and less environmental pollution compared to its natural counterpart.

Moreover, the cost efficiency of synthetic indigo cannot be overstated. Natural indigo can be significantly more expensive due to the need for extensive agricultural practices and potential scarcity. In contrast, synthetic indigo is produced in large quantities, making it accessible to various manufacturers worldwide. This democratization of color has empowered smaller companies and artisans to experiment with bold dye techniques previously reserved for more prominent brands.

Environmental Considerations

Despite the advantages, concerns over the environmental impact of synthetic dyes persist. Many manufacturers are now leveraging technology to address these issues, introducing innovations like closed-loop systems that minimize water usage and recycling effluents by treating wastewater before discharge. Industry partnerships with environmental organizations and adherence to international guidelines are also becoming more common as manufacturers strive for sustainable practices.

Future Prospects

Looking ahead, synthetic indigo powder manufacturers are likely to continue evolving in response to both consumer preferences and regulatory pressures. The future will see further innovations in biodegradable dyes, alternative eco-friendly synthesis techniques, and more efficient manufacturing processes. As consumers become more conscious of their purchasing choices, the demand for sustainable and high-quality synthetic indigo will likely rise, pushing manufacturers to stay ahead of the curve.

Conclusion

In conclusion, synthetic indigo powder manufacturers are at the forefront of a significant shift in the textile industry, combined with environmental responsibility and cost-effectiveness. As this sector continues to develop, it represents not only a technological achievement but also a commitment to sustainability and innovation. The evolution of synthetic indigo stands as a testament to the power of chemistry and manufacturing in meeting the needs of modern society while being mindful of our planet.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.