Top Suppliers for Indigo Yarn Dyeing with Quality Products and Sustainable Practices in the Textile Industry

Indigo Yarn Dyeing Suppliers A Deep Dive into Sustainable Practices

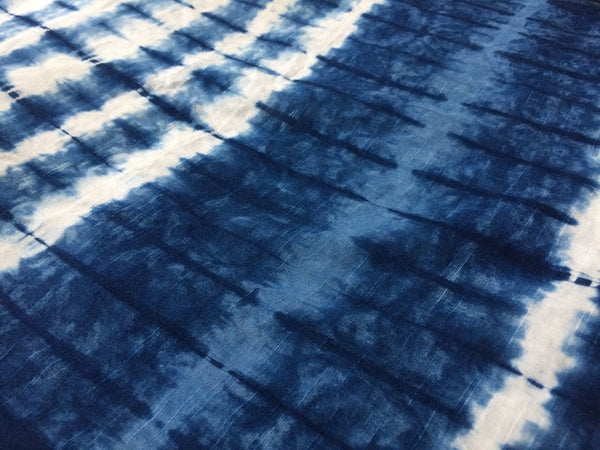

Indigo dyeing has been a cherished technique for centuries, celebrated not only for the rich, vibrant hues it produces but also for its cultural significance across various regions. As the fashion industry becomes increasingly conscious of environmental sustainability, the demand for indigo yarn dyeing suppliers who prioritize eco-friendly practices has surged. This article explores the landscape of indigo yarn dyeing suppliers, emphasizing their sustainable methods and the impact on the textile industry.

One of the most compelling aspects of indigo dyeing is its historic and cultural roots. Originating from plants like Indigofera tinctoria, indigo dyeing dates back thousands of years, with evidence of its use in ancient civilizations from Asia to Africa. Today, the traditional methods are being fused with modern technology, leading to innovative practices that maintain quality while reducing environmental impact.

Sustainable Practices in Indigo Dyeing

Sustainability is at the forefront of many indigo yarn dyeing suppliers' practices. Traditional indigo dyeing involves fermentation processes that can be resource-intensive. However, suppliers are now exploring more sustainable alternatives. Many are turning to natural indigo extraction methods that do not compromise on quality while minimizing water usage and chemical runoff. This shift is crucial in reducing the textile industry's overall carbon footprint.

Additionally, some suppliers are adopting the use of organic cotton and other natural fibers in conjunction with indigo dyeing. By sourcing organic raw materials, these suppliers help to eliminate the use of harmful pesticides and fertilizers, fostering a healthier environment. This movement towards organic textiles is not merely a trend; it reflects a growing consumer demand for ethically produced products.

Innovations in Indigo Dyeing Techniques

indigo yarn dyeing suppliers

Technological advancements are also playing a significant role in shaping how indigo yarn is dyed. Suppliers are increasingly utilizing advanced dyeing machines that require less water and energy. These machines are designed to ensure even dye penetration while reducing chemical usage. Moreover, some companies have developed techniques that allow for the recycling of dye baths, further minimizing waste. This innovative approach not only conserves resources but also contributes to a circular economy within the textile industry.

Furthermore, digital printing technologies are being employed to complement traditional dyeing processes. This allows for intricate patterns and designs without the extensive use of water and chemicals associated with conventional dyeing methods. As a result, consumers can enjoy unique, high-quality fabrics that are both aesthetically pleasing and environmentally friendly.

The Role of Education and Certification

As awareness of sustainable practices grows, so does the need for education in the textile sector. Many indigo yarn dyeing suppliers are now offering workshops and training programs to educate artisans and manufacturers about sustainable dyeing techniques. This knowledge transfer is invaluable for preserving traditional indigo dyeing methods while promoting eco-friendly practices.

Additionally, certifications such as the Global Organic Textile Standard (GOTS) are becoming critical benchmarks for suppliers looking to establish trust with consumers. These certifications ensure transparency and accountability in sourcing, production, and labor practices, fostering a more ethical textile market.

Conclusion

The journey of indigo yarn dyeing suppliers reflects a broader narrative in the textile industry—a movement toward sustainability, innovation, and ethical responsibility. As consumers increasingly seek environmentally conscious products, suppliers who embrace these values will thrive. By blending traditional methods with modern technology and prioritizing education and certification, indigo yarn dyeing suppliers are carving a path toward a more sustainable future. Through their efforts, the timeless beauty of indigo can continue to be celebrated, while also contributing positively to our planet.

-

Leading Indigo Blue Granular Company for Quality Granules & Export

NewsAug.31,2025

-

Sulphur Black Dye: Deep Black, High Fastness for Textile & Denim

NewsAug.30,2025

-

Black Sulfide: The Molecular Alchemy Behind Superior Textile Coloring

NewsAug.29,2026

-

The Uses Of Indigo Dyeing Cotton Yarn Dye

NewsAug.29,2025

-

The Dye Performance Of Bromo Indigo Blue

NewsAug.29,2025

-

Sulphur Black Dyes Enhance Color Fastness

NewsAug.29,2025

-

Indigo Blue Powder's Chemistry Intrigues

NewsAug.29,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.