Wholesale Indigo Dyeing Machines for Efficient and Sustainable Textile Production Solutions

The Evolution and Importance of Wholesale Indigo Dyeing Machines

Indigo dyeing has a rich history that dates back thousands of years. This ancient practice, particularly prominent in textile production, has seen significant transformation with the advent of technology. Today, wholesale indigo dyeing machines play a crucial role in the textile industry, catering to the demands of modern fashion while ensuring efficiency and sustainability.

Indigo, a natural dye derived from the plant Indigofera, was once laboriously extracted and applied using traditional methods. Artisans would meticulously dye textiles by hand, a process that was not only time-consuming but also limited in scalability. With the growth of textile demand in the modern era, manufacturers sought ways to streamline production without sacrificing the quality and authenticity that indigo dyeing offers.

This need led to the development of wholesale indigo dyeing machines. These machines are designed to automate the dyeing process, allowing for greater volumes of fabric to be dyed in a shorter time. The mechanism typically involves a series of sophisticated operations, including dipping, oxidation, and rinsing, all meticulously controlled to ensure even distribution and vibrancy of the indigo shade.

One of the most significant advantages of wholesale indigo dyeing machines is their ability to produce consistent color results. Traditional dyeing methods often led to variations in shade, influenced by factors such as dye concentration, exposure time, and even environmental conditions. Modern machines eliminate much of this variability, enabling manufacturers to achieve a uniform color across large production batches. This consistency is crucial for fashion brands that require reliability in their supply chains.

wholesale indigo dyeing machine

Furthermore, the eco-friendly design of some contemporary dyeing machines has contributed to a more sustainable dyeing process. Innovations in technology have enabled the development of closed-loop systems where water usage is minimized, and waste is significantly reduced. Advanced machines can also utilize synthetic indigo, which has less environmental impact compared to its natural counterpart. Such practices not only address environmental concerns but also appeal to an increasingly eco-conscious consumer base.

In addition to efficiency and sustainability, wholesale indigo dyeing machines often come equipped with digital technologies. Automation and smart controls enable manufacturers to monitor the dyeing process in real-time, leading to quicker adjustments and reduced waste. This evolution in technology enhances not only production efficiency but also the overall quality of the dyed fabric, allowing for intricate patterns and designs that were previously difficult to achieve.

Moreover, the shift toward wholesale dyeing machines has democratized indigo dyeing. Smaller manufacturers and independent designers can access these machines, opening up opportunities for creativity and innovation. This versatility allows for diverse applications, from high-fashion garments to everyday wear, thereby attracting a broader customer base.

However, it is essential to recognize that while machines have transformed the indigo dyeing process, they do not completely replace the artistry of manual dyeing. Many artisans still prefer traditional methods for bespoke projects or limited collections, where personal touch and craftsmanship are critical. The coexistence of machine and handcrafted dyeing continues to enrich the textile landscape.

In conclusion, wholesale indigo dyeing machines represent a significant advancement in the textile industry, combining efficiency, sustainability, and creativity. As fashion trends evolve and consumer demands increase, these machines will undoubtedly play an integral role in shaping the future of indigo dyeing. Embracing both technology and tradition, the indigo dyeing process continues to thrive, blending the old with the new in a vibrant tapestry of innovation.

-

innovating-bromo-indigo-excellence

NewsAug.23,2025

-

pioneering-indigo-plant-dye-excellence

NewsAug.23,2025

-

leading-sulphur-black-dyes-enterprise

NewsAug.23,2025

-

sulphur-black-dyes-light-resistance

NewsAug.23,2025

-

indigo-blue-granular-industrial-uses

NewsAug.23,2025

-

bromo-indigo-synthetic-production-process

NewsAug.23,2025

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

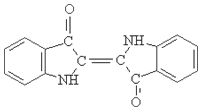

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.