indigo manufacturing

Environmental considerations are paramount in today’s manufacturing landscape, setting standards for trustworthiness. Indigo manufacturing has adapted by integrating sustainable practices. Pioneers in eco-friendly dyeing processes use closed-loop systems that recover and reuse water and chemicals, significantly minimizing environmental impact. Furthermore, some manufacturers are revisiting natural indigo sources, focusing on organic cultivation methods that reduce chemical dependencies. This return to natural processes is not merely nostalgic; it is a deliberate strategy to attract eco-conscious consumers, secure in the knowledge that sustainability increases both product appeal and industry credibility. Quality control is another essential aspect of indigo manufacturing, drumming up trust and authority in the marketplace. Rigorous testing at every stage of production— from selection of raw materials to the finishing touches on the dyed fabric—ensures that the indigo dye adheres consistently and withstands the test of wear. Manufacturers invest in state-of-the-art labs to simulate various wear-and-wash scenarios, providing solid assurance that their products will maintain their luster and durability, reinforcing consumer trust. Moreover, the indigo manufacturing sector continuously leverages data analytics and artificial intelligence to refine processes further. These technologies monitor production trends and predict future demands, permitting responsive adjustments in production strategies. This adaptability underscores a manufacturer's expertise, positioning them not only as industry leaders but as reliable partners capable of meeting evolving market needs. In conclusion, indigo manufacturing today is an exemplar of experience, expertise, authority, and trustworthiness. By integrating time-honored practices with modern innovations, it meets present and future demands while maintaining a respectful nod to its venerable past. From ensuring sustainable practices to modernizing through technology, indigo manufacturers are crafting products that satisfy the complex criteria of producing responsibly while delivering a timeless aesthetic. And in doing so, they affirm their place not only as vanguards of a craft but as stewards of a legacy, well-equipped to navigate the future of textile production.

-

innovating-bromo-indigo-excellence

NewsAug.23,2025

-

pioneering-indigo-plant-dye-excellence

NewsAug.23,2025

-

leading-sulphur-black-dyes-enterprise

NewsAug.23,2025

-

sulphur-black-dyes-light-resistance

NewsAug.23,2025

-

indigo-blue-granular-industrial-uses

NewsAug.23,2025

-

bromo-indigo-synthetic-production-process

NewsAug.23,2025

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

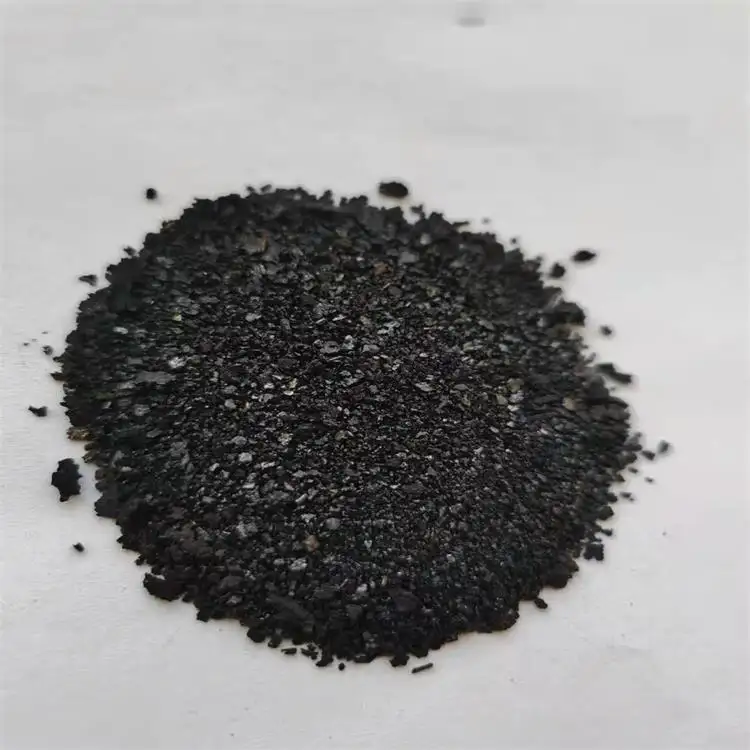

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.