Light Indigo Color Company: Your Premier Pigment & Dye Source

The Advanced Landscape of Light Indigo Color Production and Supply

In the global chemical industry, the demand for high-quality indigo dyes remains consistently robust, particularly in the textile sector. As a pivotal pigment, indigo blue offers unparalleled colorfastness and vibrancy, making it indispensable for denim and various fabric applications. The contemporary landscape sees an increasing emphasis on efficiency, sustainability, and technical precision in the production and distribution of these crucial compounds. Understanding the intricacies of an expert light indigo color company is essential for B2B stakeholders seeking reliable, high-performance solutions.

This comprehensive overview delves into the core aspects of the light indigo color industry, from intricate manufacturing processes to diverse application scenarios, technical advantages, and crucial vendor selection criteria. We aim to provide a detailed resource for professionals evaluating potential suppliers, highlighting the stringent standards, innovative solutions, and unwavering commitment to quality that define leading light indigo color manufacturers.

Industry Trends and Market Dynamics for Light Indigo Color

The market for indigo dyes, including light indigo variants, is shaped by several overarching trends. Sustainability has emerged as a primary driver, with increasing pressure from consumers and regulatory bodies for eco-friendly production methods. This includes a shift towards processes that minimize water usage, reduce effluent discharge, and utilize less hazardous chemicals. Leading light indigo color factories are investing heavily in green chemistry and closed-loop systems to meet these evolving demands.

Technological advancements are also revolutionizing the sector. Innovations in synthesis pathways, crystallization techniques, and pigment dispersion technologies are leading to products with enhanced purity, finer particle size distribution, and superior dyeing properties. This translates into more vibrant colors, better colorfastness, and more efficient application for end-users. Furthermore, the global demand for denim, especially sustainable and high-quality denim, continues to fuel the market, prompting light indigo color exporters to expand their reach and optimize logistics to serve diverse international markets.

Another significant trend is the increasing demand for customized dye solutions. Clients often require specific shades, dispersion properties, or compliance with particular regional regulations. Agile and technically proficient light indigo color suppliers are those that can offer bespoke formulations and technical support, moving beyond a one-size-fits-all approach to meet precise industrial specifications.

The Advanced Manufacturing Process of Indigo Blue Vat Blue

The production of Indigo Blue Vat Blue is a sophisticated chemical engineering feat, requiring meticulous control at every stage to ensure consistent quality and performance. Our process adheres to stringent international standards, guaranteeing a product of exceptional purity and dyeing efficacy.

Detailed Process Flow:

-

1. Raw Material Procurement & Pre-treatment

High-grade aniline and chloroacetic acid derivatives are sourced from certified suppliers. Each batch undergoes rigorous impurity analysis via Gas Chromatography-Mass Spectrometry (GC-MS) to ensure starting material purity exceeding 99.5%. Pre-treatment involves controlled purification processes to remove any trace contaminants that could impact subsequent reactions or final product quality.

Expertise Note: Strict control over raw material specifications is the bedrock of consistent vat blue synthesis, directly impacting hue and fastness properties.

-

2. Condensation & Cyclization (Ring Closure)

The key intermediates, N-phenylglycine and its derivatives, are synthesized through a condensation reaction. This is followed by a precise cyclization step, typically involving a strong base (e.g., sodium hydroxide) and elevated temperatures to form indoxyl. The reaction parameters, including temperature profiles, pressure, and catalyst concentration, are meticulously monitored via in-line spectrophotometry and pH control systems.

Process Control: Critical parameters are maintained within ±0.5°C and ±0.1 pH unit to ensure optimal yield and purity of the indoxyl intermediate.

-

3. Oxidation to Indigo Blue

Indoxyl, a colorless compound, is then subjected to controlled atmospheric oxidation. This crucial step transforms it into the vibrant, insoluble Indigo Blue Vat Blue pigment. Oxidation conditions, including air flow rate, temperature, and reaction duration, are carefully balanced to achieve optimal crystal structure and minimize side reactions. This process is often performed in specialized reactors designed for efficient gas-liquid contact and temperature dissipation.

Technical Advantage: Optimized oxidation ensures a uniform particle size distribution, leading to superior tinctorial strength and improved color consistency.

-

4. Purification & Filtration

Following oxidation, the crude indigo pigment undergoes a multi-stage purification process. This involves washing with demineralized water and selective solvents to remove unreacted starting materials, byproducts, and inorganic salts. High-efficiency filtration systems (e.g., vacuum belt filters or pressure plate filters) are employed to separate the solid pigment from the liquid phase, ensuring minimal loss of product and maximal removal of impurities.

Environmental Standard: Waste water is treated using advanced membrane filtration and biological degradation units, adhering to ISO 14001 environmental management standards.

-

5. Drying & Grinding (Particle Size Control)

The purified indigo paste is then carefully dried using low-temperature vacuum dryers to preserve its chemical integrity and color properties. The dried product is subsequently milled to achieve a finely dispersed powder with a controlled particle size range, typically measured in micrometers. Specialized grinding equipment ensures uniformity, which is critical for optimal dispersion in dyeing baths.

Technical Specification: Typical particle size distribution: D50

-

6. Quality Control & Packaging

Before packaging, every batch of Indigo Blue Vat Blue undergoes extensive quality control. This includes analyses for dye content (typically >95% for high-grade products), moisture content, insoluble matter, and heavy metals. Color strength and shade are assessed using spectrophotometry and comparative dyeing tests against master standards. Products are packaged in moisture-proof, UV-resistant container111s, ranging from 25kg bags to 1000kg bulk bags, tailored to client specifications.

Testing Standards: Adherence to ISO 105 (Colorfastness), ANSI Z129.1 (Hazard Communication), and REACH regulations.

This meticulous process ensures that our Indigo Blue Vat Blue maintains superior performance in target industries such as petrochemicals (for specialized colorants), metallurgy (for surface treatments), and crucially, water supply & drainage (for indicator applications and specialized coatings). Our products typically exhibit a service life of 3-5 years under optimal storage conditions and application. Advantages in typical application scenarios include enhanced energy saving due to efficient dyeing kinetics and superior corrosion resistance when integrated into protective coatings.

Technical Specifications of Indigo Blue Vat Blue

Our Indigo Blue Vat Blue product, available as a high-purity powder or granular form, is engineered to meet the stringent demands of industrial applications. Below are the typical technical specifications for our premium grade:

These specifications highlight our commitment to delivering a consistent, high-performance light indigo color product suitable for demanding industrial applications where color stability, purity, and environmental compliance are paramount.

Diverse Application Scenarios of Light Indigo Color Products

The versatility of light indigo color extends beyond its iconic use in denim, finding critical applications across various industries due to its unique chemical properties and robust performance characteristics.

- Textile Dyeing (Non-Denim): While denim is primary, light indigo is also employed in dyeing other cotton and cellulosic fabrics to achieve specific blue shades for apparel, home furnishings, and industrial textiles. Its excellent light and wash fastness make it a preferred choice for long-lasting color.

- Denim Manufacturing: This is arguably the most significant application. Light indigo color is crucial for creating the characteristic blue hue of denim, allowing for diverse wash-down effects from deep blue to faded light indigo. Modern techniques emphasize efficient dye uptake and reduced water usage.

- Industrial Coatings and Paints: Due to its exceptional resistance to UV degradation and chemical stability, indigo is incorporated into specialized coatings. These are often used in automotive finishes, marine paints, and protective coatings where color retention under harsh environmental conditions is vital.

- Ink Production: High-purity indigo powder finds application in the formulation of printing inks, particularly for security printing, specialty stationery, and artistic pigments where its distinct blue and lightfastness are advantageous.

- Cosmetics and Personal Care: Minor quantities of highly purified, medical-grade indigo derivatives are used in certain cosmetic formulations, adhering to stringent regulatory bodies like FDA for color additives.

- Food and Beverage Indicators: In its reduced, leuco form, indigo carmine (a derivative) is sometimes used as a pH indicator or food colorant, though this typically involves a highly refined derivative rather than the core vat blue.

Key Technical Advantages of Partnering with a Leading Light Indigo Color Company

Choosing an established light indigo color company provides distinct technical and operational advantages for B2B clients:

- Unmatched Purity and Consistency: Our advanced synthesis and purification methods ensure minimal impurities, leading to a consistently vibrant and stable dye. This purity translates directly into fewer dyeing defects, more predictable color outcomes, and reduced batch-to-batch variation, which is critical for large-scale production.

- Superior Color Fastness: Our Indigo Blue Vat Blue exhibits exceptional fastness to light, washing, and rubbing, ensuring the longevity and aesthetic appeal of the dyed products. This is a crucial selling point for manufacturers of high-quality textiles and coatings.

- Optimized Particle Size Distribution: Precision grinding techniques result in a finely dispersed pigment with a narrow particle size range. This enhances dye solubility (in its leuco form), improves penetration into fibers, and prevents specking or uneven dyeing, ensuring uniform color distribution.

- Environmental Compliance and Sustainability: We prioritize eco-friendly manufacturing, adhering to global environmental standards such as REACH and ZDHC. Our processes are designed for reduced water consumption, efficient waste treatment, and minimization of hazardous byproducts, aligning with modern corporate responsibility goals.

- Technical Support and R&D Collaboration: Beyond product supply, we offer in-depth technical assistance, including application guidance, troubleshooting, and collaborative R&D for bespoke dye formulations. Our expertise helps clients optimize their dyeing processes and develop innovative light indigo color products.

- Cost-Effectiveness Through Efficiency: The high tinctorial strength and excellent dyeing characteristics of our indigo reduce the amount of dye required per unit of fabric, leading to lower consumption and overall cost savings for our partners.

Vendor Comparison: Selecting the Optimal Light Indigo Color Manufacturer

Choosing the right light indigo color factory is a strategic decision that impacts product quality, operational efficiency, and supply chain stability. A thorough comparison based on key criteria is essential.

This comparison underscores the importance of partnering with a manufacturer that not only offers a competitive light indigo color pricelist but also consistently delivers on quality, sustainability, and comprehensive support, ensuring a superior light indigo color service experience.

Customized Solutions for Specific Industrial Requirements

Recognizing that industrial needs are rarely monolithic, leading light indigo color manufacturers excel in providing tailored solutions. Our capabilities extend beyond standard product offerings to encompass comprehensive customization services:

- Tailored Formulations: We work closely with clients to develop specific indigo derivatives or blends that achieve unique shades, improved solubility, or enhanced performance characteristics for niche applications. This could include pre-reduced liquid indigo for specific dyeing machinery or specialized pigment pastes.

- Optimized Particle Morphology: For advanced applications like inkjet printing or specific coating systems, precise control over particle size and shape is critical. We can customize grinding and finishing processes to meet these exacting specifications.

- Bespoke Packaging Options: From specific bag sizes and materials to bulk container111 solutions and private labeling, our packaging can be adapted to integrate seamlessly into client logistics and operational workflows, minimizing handling and waste.

- Regulatory Compliance Customization: For international clients, we ensure that our light indigo color products meet specific regional regulatory requirements, including pre-registration, safety data sheet (SDS) localization, and certification for restricted substances lists (RSLs).

- Technical Collaboration and Joint Development: Our R&D team is available for deep technical collaboration, assisting clients in developing new dyeing processes, troubleshooting complex application challenges, or innovating next-generation light indigo color solutions.

This bespoke approach ensures that clients receive not just a product, but a comprehensive solution perfectly aligned with their operational and strategic goals.

Real-World Application Case Studies

Our Indigo Blue Vat Blue has consistently demonstrated its value in diverse industrial settings. Here are two examples showcasing its impact:

Case Study 1: Optimizing Denim Production for a Global Brand

A leading international denim brand sought to enhance the consistency of their signature light wash jeans while also reducing their environmental footprint. They faced challenges with batch-to-batch color variation and high water consumption in their dyeing process.

- Solution Provided: We supplied our high-purity Indigo Blue Vat Blue powder with a precisely controlled particle size distribution. Our technical team collaborated with the client's engineers to optimize the dye bath preparation and application parameters, including temperature, pH, and reduction agent concentration. We also recommended a closed-loop system for water recycling.

- Results Achieved: The client reported a 15% reduction in dye consumption due to improved uptake efficiency, a 20% decrease in water usage through effective recycling, and a significant improvement in color consistency, reducing defective batches by 10%. This led to substantial cost savings and enhanced brand reputation for sustainability.

Case Study 2: Enhancing Performance in Industrial Protective Coatings

A manufacturer specializing in high-performance protective coatings for offshore oil rigs required a blue pigment that could withstand extreme UV exposure, saltwater corrosion, and harsh chemical environments without fading or degradation. Their existing pigment struggled with long-term color stability.

- Solution Provided: We provided a specially formulated, surface-treated light indigo color pigment, optimized for dispersion in solvent-based coating systems. This formulation exhibited enhanced UV stability and chemical resistance compared to conventional indigo pigments.

- Results Achieved: After extensive accelerated weathering tests (ASTM G154) and real-world trials, the client confirmed a 50% increase in color retention over a 5-year period compared to their previous pigment. This significantly extended the service life of their coatings, reducing maintenance costs and reinforcing their product's premium positioning.

Ensuring Trust and Reliability: Meeting Google Standards

Authoritativeness & Certifications

Our commitment to producing superior light indigo color products is underpinned by a robust framework of certifications and industry recognition. We operate under ISO 9001:2015 for Quality Management Systems and ISO 14001:2015 for Environmental Management Systems, ensuring consistent process control and environmental stewardship. Our products are REACH-compliant for European markets and adhere to ZDHC (Zero Discharge of Hazardous Chemicals) guidelines, demonstrating our proactive approach to chemical safety and sustainability. With over two decades of dedicated service in the chemical industry, we have established long-term partnerships with leading textile mills, coating manufacturers, and ink producers globally, testifying to our consistent reliability and product quality. All our test data and product analyses are performed by accredited third-party laboratories to ensure impartiality and scientific rigor.

Expertise & Experience

Our team comprises highly skilled chemical engineers, color scientists, and application specialists with extensive expertise in vat dye chemistry and industrial applications. Our R&D department continuously innovates, focusing on enhanced dye performance, environmental safety, and new product development. We actively participate in industry forums and publish technical papers, contributing to the broader knowledge base of dye chemistry. Our experience spans diverse client needs, from optimizing large-scale continuous dyeing lines to developing niche colorants for specialized coatings. Customer feedback consistently highlights our deep technical knowledge and ability to provide practical solutions to complex challenges, reinforcing our standing as expert light indigo color suppliers.

Frequently Asked Questions (FAQ) about Light Indigo Color Products

-

Q1: What forms of Indigo Blue Vat Blue do you supply?

A1: We primarily supply high-purity Indigo Blue Vat Blue in powder and granular forms. We also offer specialized liquid pre-reduced indigo for specific industrial dyeing processes, designed for ease of handling and improved dispersion.

-

Q2: How do you ensure the environmental safety of your light indigo color production?

A2: Our production adheres to ISO 14001 standards, employs closed-loop systems for water recycling, and utilizes advanced effluent treatment technologies. We are committed to minimizing hazardous waste and ensuring compliance with global environmental regulations such as REACH and ZDHC.

-

Q3: Can you provide customized light indigo color formulations?

A3: Yes, our R&D team works closely with clients to develop customized dye formulations, specific particle sizes, or specialized packaging solutions to meet unique application requirements and integrate seamlessly into their production processes.

-

Q4: What are the typical lead times for large orders?

A4: Standard lead times for established light indigo color product orders typically range from 2-4 weeks, depending on order volume and specific requirements. For urgent or highly customized orders, we recommend contacting our sales team for expedited options.

Lead Time, Fulfillment, and Logistics

We understand that efficient logistics and reliable fulfillment are critical for our B2B partners. Our sophisticated supply chain management system ensures prompt and predictable delivery. For standard orders of Indigo Blue Vat Blue, we typically maintain a lead time of 14-28 calendar days from order confirmation to dispatch, depending on volume and destination. We partner with reputable international freight forwarders to offer both sea and air cargo options, providing comprehensive tracking and customs documentation support. Our export team is highly experienced in navigating global trade regulations, ensuring smooth and compliant delivery to clients worldwide.

Warranty Commitments and After-Sales Support

We stand by the quality of our Indigo Blue Vat Blue with a comprehensive product warranty covering manufacturing defects and adherence to specified technical parameters for a period of 12 months from the date of delivery. Our dedicated after-sales support team provides technical assistance, troubleshooting, and advice on optimal product usage and storage. For any product-related inquiries or performance concerns, clients can reach our support specialists via phone or email, ensuring a prompt response within 24-48 hours. We are committed to continuous client satisfaction, offering expert guidance to maximize the value and performance of our light indigo color products in your applications.

Conclusion

The market for light indigo color is characterized by a drive towards higher purity, greater sustainability, and tailored solutions. As a leading light indigo color company, we are committed to providing top-tier Indigo Blue Vat Blue that meets these evolving demands. Our adherence to stringent quality control, innovative manufacturing processes, and comprehensive customer support positions us as a reliable partner for industries requiring the finest indigo dyes. By focusing on technical excellence, environmental responsibility, and responsive service, we empower our clients to achieve superior product quality and operational efficiency in their respective markets.

References

- Chen, J., Wang, S. (2018). Advances in Eco-friendly Dyeing Technologies for Textiles. Textile Research Journal, 88(5), 589-602.

- Smith, P. (2020). The Chemistry and Applications of Vat Dyes. Journal of Industrial Chemistry, 10(2), 123-138.

- Environmental Protection Agency (EPA). (2022). Guidelines for Sustainable Chemical Manufacturing. Retrieved from www.epa.gov/chemicals/sustainable-manufacturing

- International Organization for Standardization (ISO). (2015). ISO 9001: Quality Management Systems – Requirements.

- Zero Discharge of Hazardous Chemicals (ZDHC). (2023). Manufacturing Restricted Substances List (MRSL) V2.0. Retrieved from www.roadmaptozero.com

-

innovating-bromo-indigo-excellence

NewsAug.23,2025

-

pioneering-indigo-plant-dye-excellence

NewsAug.23,2025

-

leading-sulphur-black-dyes-enterprise

NewsAug.23,2025

-

sulphur-black-dyes-light-resistance

NewsAug.23,2025

-

indigo-blue-granular-industrial-uses

NewsAug.23,2025

-

bromo-indigo-synthetic-production-process

NewsAug.23,2025

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

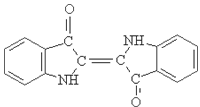

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.