Light Indigo Color: Your Premier Pigment Company & Supplier

Driving Innovation in Industrial Coloration: The Role of a Leading Light Indigo Color Company

In the dynamic landscape of industrial manufacturing, the demand for high-performance and aesthetically appealing colorants continues to escalate. Among these, the sophisticated hue of light indigo holds significant sway, particularly within the textile, paper, and specialty chemical sectors. A truly distinguished light indigo color company stands at the forefront of this evolution, not merely supplying pigments but delivering comprehensive solutions that integrate advanced chemistry with sustainable manufacturing practices. This article delves into the intricate world of light indigo coloration, focusing on the technical expertise, robust manufacturing processes, and unwavering commitment to quality that defines industry-leading suppliers like Wuxin-Group, a prominent supplier of Indigo Blue Vat Blue.

We will explore the critical industry trends, detailed technical parameters, diverse application scenarios, and the inherent technical advantages offered by a premier light indigo color company. Furthermore, we will provide insights into vendor comparison, customization capabilities, real-world application cases, and the foundational elements of trust and authority that underpin successful B2B partnerships in this specialized domain.

Industry Trends and Market Dynamics for Light Indigo Colorants

The market for light indigo colorants is characterized by several prevailing trends. Firstly, there is a pronounced shift towards eco-friendly and sustainable manufacturing processes. Consumers and regulatory bodies alike demand products with reduced environmental footprints, pushing light indigo color manufacturers to invest in cleaner synthesis routes, efficient wastewater treatment, and lower energy consumption during production. This includes the development of dyes that require less water and fewer auxiliary chemicals in application.

Secondly, technological advancements are continually refining the performance characteristics of light indigo dyes. Innovations in particle size control, dispersion technology, and formulation optimization lead to superior color fastness, shade consistency, and ease of application. This ensures that the final product, whether a denim fabric or a specialty paper, meets stringent quality benchmarks. The rise of automation and IoT in chemical production also plays a crucial role in enhancing efficiency and precision for light indigo color factories.

Thirdly, customization and specialized solutions are becoming paramount. Clients often require specific shades, application properties, or regulatory compliance for their unique product lines. This necessitates a flexible and responsive light indigo color company capable of tailored product development and technical support.

Technical Parameters and Specifications of Indigo Blue Vat Blue

Understanding the technical specifications of Indigo Blue Vat Blue is crucial for industries relying on consistent and high-quality coloration. This product, manufactured by a leading light indigo color company, adheres to rigorous standards to ensure optimal performance.

- Chemical Structure and Purity: Indigo Blue Vat Blue is a complex organic compound, specifically a vat dye. Its purity, typically exceeding 98% for premium grades, is critical for achieving consistent color yield and shade. Impurities can lead to off-shades, reduced color intensity, or poor fastness properties.

- Color Index (CI) and CAS Number: Generally, Indigo Blue has CI Vat Blue 1 and CAS No. 482-89-3, providing a universal identification standard in the chemical industry.

- Particle Size Distribution: Optimal particle size (often measured as D50 or D90) is vital for proper dispersion and penetration into textile fibers. Finer particles typically offer better color strength and leveling properties, crucial for uniform dyeing.

- Shade Consistency (ΔE): Measured using spectrophotometry, a low Delta E (ΔE) value signifies minimal color variation between batches, ensuring reliable reproduction of specific light indigo shades. A ΔE value of less than 0.5 is often targeted for high-precision applications.

- Color Fastness Properties: This includes resistance to light (lightfastness, e.g., ISO 105-B02), washing (washfastness, e.g., ISO 105-C06), rubbing (crockfastness), and perspiration. These properties dictate the dye's durability and longevity in various end-use applications. For vat dyes, fastness properties are typically excellent, especially for light and wet fastness.

- Solubility/Dispersibility: While vat dyes are generally insoluble in water in their pigment form, they are converted to a soluble leuco form for dyeing. Their dispersibility in the dyeing bath is crucial for even absorption.

- Moisture Content: Low moisture content indicates better stability and concentration of the active dye.

Precision quality control is paramount for any reputable light indigo color company.

These parameters collectively define the quality and suitability of Indigo Blue Vat Blue for demanding industrial applications, showcasing the meticulous approach of leading light indigo color manufacturers.

The Manufacturing Process: Precision and Purity at a Light Indigo Color Company

The production of high-grade Indigo Blue Vat Blue by a specialized light indigo color company is a sophisticated multi-stage chemical synthesis and processing endeavor. Unlike generic manufacturing, it involves stringent control over chemical reactions, crystallization, and purification to ensure the desired purity, shade, and particle characteristics.

1. Raw Material Sourcing and Preparation:

- Precursors: High-purity aniline and acetic anhydride are common starting materials. A leading light indigo color factory ensures these precursors meet strict quality specifications to prevent impurities from compromising the final product.

- Pre-treatment: Raw materials may undergo filtration or distillation to remove any contaminants before entering the synthesis phase.

2. Chemical Synthesis (Indigotin Formation):

- Reaction Pathways: The core synthesis involves reactions such as the Heumann synthesis or modified processes. For Indigo Blue, this typically starts with N-phenylglycine, which cyclizes and then dimerizes to form indigotin.

- Controlled Environment: Reactions are conducted in precisely controlled reactors, where parameters such as temperature, pressure, pH, and stirring speed are meticulously monitored and adjusted using advanced process control systems (e.g., DCS - Distributed Control Systems). This ensures optimal reaction yield and minimizes undesirable by-products.

- Automation and Precision: Modern light indigo color manufacturers utilize automated dosing systems and real-time analytical feedback to maintain ideal conditions, preventing batch variations.

3. Purification and Isolation:

- Crystallization: After synthesis, the crude indigo is crystallized to enhance purity. This step is critical for defining the crystal structure and size, which directly impacts the dye's color strength and dispersibility.

- Filtration and Washing: The crystallized indigo is then filtered to separate it from the mother liquor, followed by multiple washing steps to remove soluble impurities. High-pressure filtration systems and dewatering equipment are essential here.

- Drying: The wet cake is dried using controlled drying methods (e.g., spray drying, tray drying) to achieve the desired moisture content. Excessive heat can degrade the dye, so precise temperature control is vital.

4. Standardization and Finishing:

- Milling and Grinding: The dried dye is milled to a very fine, uniform particle size using specialized grinding equipment. This ensures excellent dispersibility and color development in the dyeing process. Advanced mills prevent heat buildup that could damage the dye.

- Batch Blending and Standardization: Different batches may be blended to achieve perfect shade consistency and strength, ensuring that every shipment from the light indigo color company meets the exact specifications. This involves sophisticated spectrophotometric analysis.

- Formulation: Depending on the end application, the dye might be formulated into various forms (e.g., powder, granular, paste) with dispersing agents or other additives to optimize performance.

Simplified process flow highlighting critical stages in a light indigo color factory.

Quality Control and Certification Standards:

Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes in-process testing at each stage, from raw material inspection to final product analysis. Industry-standard testing methods such as ISO (International Organization for Standardization) for quality management (e.g., ISO 9001:2015), environmental management (e.g., ISO 14001:2015), and specific textile testing standards are meticulously followed. For instance, tests for shade, strength, purity, moisture content, particle size, and various fastness properties are routinely performed. Adherence to global chemical regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is also a hallmark of a responsible light indigo color company.

The longevity and performance ("service life") of Indigo Blue Vat Blue are inherently tied to its intrinsic fastness properties. Its exceptional resistance to fading from light exposure, washing, and chemical agents ensures that products dyed with it maintain their vibrant light indigo hue for extended periods, even under demanding conditions. This long service life translates directly into enhanced product durability and customer satisfaction for downstream industries.

Applicable Industries and Application Advantages

Indigo Blue Vat Blue is a versatile colorant with widespread applicability across several industrial sectors, thanks to its unique chemical properties and superior performance. A leading light indigo color company often caters to the specific needs of these diverse industries.

- Textile Industry (especially Denim): This is the most iconic application. Indigo Blue is the quintessential dye for denim, producing the characteristic blue hue that fades beautifully over time. Beyond denim, it's used in general apparel, workwear, and home textiles where excellent fastness properties are required. The unique ring-dyeing capability of indigo, where the dye adheres to the surface of the cotton fiber, is what allows denim to develop its distinct "fades" over wear and washing.

- Paper Industry: Used for coloring specialty papers, packaging materials, and paperboards where a specific shade of blue is desired, often for branding or aesthetic appeal. The dye’s stability ensures color integrity in various paper production processes.

- Printing Inks: In certain high-quality printing applications, particularly for security documents or specialized graphic arts, indigo pigments can be incorporated for their unique shade and stability.

- Other Specialty Applications: This can include applications in the coating industry, for specific plastics, or even in some cosmetic products, provided regulatory approvals are met.

Key Advantages in Typical Application Scenarios:

- Exceptional Color Fastness: Indigo Blue Vat Blue offers superior lightfastness, washfastness, and crockfastness compared to many other dye classes. This ensures that the dyed material retains its light indigo color and vibrancy even after prolonged exposure to environmental elements or repeated laundering. This is a primary driver for its adoption in high-wear items like denim.

- Distinctive Fading Characteristics: For denim, the unique surface dyeing property of indigo allows for desirable "fade" patterns, which are highly valued in the fashion industry. This "worn-in" look cannot be easily replicated by other dyes.

- Batch-to-Batch Consistency: A reliable light indigo color company ensures minimal shade variation between different dye lots, which is critical for continuous industrial processes and brand consistency.

- Versatility: While most famous for cotton, vat dyes can be applied to other cellulosic fibers and some blends, offering flexibility in textile design.

- Environmental Considerations: Modern production techniques by responsible light indigo color manufacturers focus on reducing chemical oxygen demand (COD) and biochemical oxygen demand (BOD) in effluents, and minimizing waste, contributing to more sustainable dyeing processes. The inherent stability of the dye reduces leaching into wastewater over the product's lifespan.

These advantages make Indigo Blue Vat Blue a preferred choice for industries where aesthetic appeal, durability, and environmental responsibility are paramount considerations, solidifying the importance of selecting a reputable light indigo color supplier.

Performance Metrics and Data-Driven Insights

To underscore the technical superiority of a leading light indigo color product, it is essential to examine key performance metrics. These quantitative values provide objective proof of quality and consistency, crucial for B2B decision-makers.

Typical Performance Parameters for Premium Indigo Blue Vat Blue:

| Parameter | Standard (Typical Range) | Test Method / Standard |

|---|---|---|

| Purity (Indigotin Content) | ≥ 98.0% | HPLC / Spectrophotometry |

| Moisture Content | ≤ 0.5% | Karl Fischer Titration |

| Particle Size (D50) | < 10 µm (typically 3-5 µm) | Laser Diffraction Spectroscopy |

| Shade Consistency (ΔE CMC 1:1) | ≤ 0.5 (against standard) | Spectrophotometer (Datacolor/X-Rite) |

| Lightfastness (ISO 105-B02) | 7-8 (on 1-8 scale, 8 being highest) | Xenon Arc Lamp Exposure |

| Washfastness (ISO 105-C06, AATCC 61) | 4-5 (on 1-5 scale, 5 being highest) | Standard Washing Machine Test |

| Crockfastness (AATCC 8/116, Dry/Wet) | 4-5 (on 1-5 scale, 5 being highest) | Crockmeter Test |

| Dispersibility | Excellent, no visible aggregates | Dispersion Stability Test |

These data points are not just numbers; they represent the rigorous quality control and advanced chemical engineering that goes into producing a top-tier light indigo color product. For manufacturers in textiles or paper, these specifications guarantee reliable performance, reduce production errors, and ultimately lead to a superior end product for their customers.

Rigorous testing ensures the highest quality from light indigo color suppliers.

Choosing Your Partner: Vendor Comparison and Selection Criteria

Selecting the right light indigo color company is a strategic decision that impacts product quality, cost-efficiency, and supply chain reliability. While numerous light indigo color exporters exist, discerning buyers focus on several key criteria:

- Quality and Consistency: Foremost, ensure the supplier consistently delivers products meeting stringent technical specifications (as outlined in the table above). Requesting Certificates of Analysis (CoA) for each batch and conducting independent verification are good practices.

- Technical Support and R&D Capabilities: A proactive light indigo color company offers robust technical support, assisting with application challenges, shade matching, and process optimization. Strong R&D capabilities indicate a commitment to innovation and future-proofing products.

- Supply Chain Reliability and Logistics: Evaluate the supplier's capacity, lead times, inventory management, and global distribution network. Timely delivery from light indigo color exporters is critical to maintain production schedules.

- Regulatory Compliance and Sustainability: Verify adherence to international chemical regulations (e.g., REACH, OEKO-TEX standards) and environmental certifications (e.g., ISO 14001). A focus on sustainable production is increasingly vital.

- Pricing Structure and Value Proposition: While the light indigo color pricelist is important, consider the overall value. A slightly higher price for superior quality, consistent supply, and excellent technical support often translates to lower overall production costs due to reduced waste, rework, and downtime.

- Experience and Reputation: Look for a light indigo color company with a proven track record, positive industry reputation, and significant years of service in the chemical sector.

By evaluating these factors comprehensively, businesses can forge lasting partnerships with light indigo color suppliers that truly add value to their operations.

Customization Solutions and Collaborative Partnerships

In the specialized B2B chemical market, one-size-fits-all solutions are rarely sufficient. A forward-thinking light indigo color company recognizes this and excels in offering bespoke solutions and fostering collaborative partnerships. This extends beyond merely providing light indigo color products; it involves becoming an extension of the client's R&D and production teams.

- Tailored Formulations: Clients often require specific shades of light indigo, optimized for particular fiber types, dyeing machinery, or desired wash-down characteristics. A leading light indigo color company can adjust particle size, dispersion properties, or add specific auxiliaries to meet these precise needs.

- Application-Specific Grades: Whether it's a powder for traditional dyeing or a high-concentration paste for continuous dyeing lines, custom grades can be developed to streamline client processes and enhance efficiency.

- Joint R&D Projects: For truly innovative applications or novel material developments, a collaborative light indigo color factory can engage in joint research and development, leveraging their chemical expertise to co-create solutions.

- Technical Consultations and On-site Support: Providing expert advice on dyeing processes, trouble-shooting, and optimizing dye consumption contributes significantly to the client's operational efficiency and cost savings. This level of light indigo color service is invaluable.

Such customized approaches and collaborative frameworks distinguish a premier light indigo color company from mere commodity suppliers, paving the way for mutual growth and technological advancement.

Real-World Application Cases and Success Stories

The true testament to a light indigo color company's capabilities lies in its successful application across various industries. While specific client names remain confidential, illustrative cases highlight the tangible benefits delivered:

Case Study 1: Denim Mill Optimization

A prominent denim mill faced challenges with inconsistent light indigo shades and high wastewater effluent from their dyeing process. Partnering with a leading light indigo color company (Wuxin-Group), they implemented a new, high-purity Indigo Blue Vat Blue product along with optimized application protocols. The result was a 15% reduction in dye consumption due to better exhaustion, a 20% decrease in water usage in rinsing stages, and achieving a tighter ΔE range of 0.3, drastically improving batch-to-batch consistency for their light indigo denim. This directly impacted their bottom line and enhanced their environmental profile.

Case Study 2: Specialty Paper Manufacturer

A manufacturer of high-end specialty papers required a light indigo shade that would not bleed when wet and would resist fading under display lighting. Existing dyes struggled to meet these stringent requirements. After collaboration with a specialized light indigo color manufacturer, a custom-formulated Indigo Blue Vat Blue, engineered for paper pulp applications, was developed. This formulation delivered superior lightfastness (rated 7 on the blue wool scale) and significantly improved wet fastness, allowing the client to launch a new line of premium, durable colored papers that quickly gained market traction. This demonstrated the value of a dedicated light indigo color service provider.

Versatile light indigo color products find diverse applications across industries.

Building Trust and Authority: The Pillars of a Reliable Light Indigo Color Company ()

In the B2B chemical sector, establishing trust and demonstrating authority are paramount. A truly credible light indigo color company integrates the principles of Expertise, Experience, Authoritativeness, and Trustworthiness () into every facet of its operations.

Expertise: Deep Chemical Knowledge and Innovation

- Dedicated R&D Teams: Comprised of organic chemists, material scientists, and application engineers specializing in dye synthesis and coloration technology.

- Industry Terminology: Fluency in terms like "chromophore," "vatting process," "redox potential," and "spectrophotometric analysis" underscores their technical depth, as seen in the discussion of Indigo Blue Vat Blue.

- Continuous Improvement: Commitment to refining synthesis routes for higher purity, better environmental profiles, and enhanced performance of light indigo color products.

Experience: Proven Track Record and Client Satisfaction

- Years in Service: A long operational history in the chemical industry signifies stability and accumulated knowledge.

- Diverse Client Portfolio: Successful partnerships with a wide range of industries globally, including top-tier textile mills and paper manufacturers.

- Customer Feedback: Positive testimonials and long-term client relationships demonstrate consistent satisfaction with the light indigo color service and products.

Authoritativeness: Certifications, Standards, and Industry Recognition

- ISO Certifications: Adherence to ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) indicates a commitment to international best practices.

- Regulatory Compliance: Full compliance with global chemical regulations such as REACH (Europe), TSCA (USA), and specific industry standards like OEKO-TEX for textile dyes.

- Testing Data & Reports: Providing comprehensive Certificates of Analysis (CoA) for every batch, alongside readily available Material Safety Data Sheets (MSDS) and technical data sheets for all light indigo color products.

- Industry Affiliations: Active participation in industry associations, chemical societies, and conferences.

Trustworthiness: Transparency, Reliability, and Support

- Delivery Cycle and Logistics: Clear, transparent communication regarding lead times, shipping options (from light indigo color exporters), and tracking capabilities ensures predictability for clients. Consistent on-time delivery.

- Quality Assurance and Warranty: Explicit quality guarantees and responsive handling of any product performance queries or issues. A robust complaint resolution process.

- Customer Support: Dedicated account managers and technical support teams available to provide timely assistance, whether for ordering or troubleshooting application issues.

- Pricing Transparency: While the light indigo color pricelist is competitive, it's also clear and free of hidden charges.

Frequently Asked Questions (FAQ)

- What is the typical lead time for an order of Indigo Blue Vat Blue?

Lead times typically range from 2-4 weeks for standard orders, depending on quantity and specific product grade. Expedited shipping options are available upon request from light indigo color suppliers. - How does your company ensure batch-to-batch consistency?

We employ a multi-stage quality control process, including rigorous in-process testing, spectrophotometric analysis of every batch, and blending of multiple batches if necessary to achieve precise shade and strength targets, all monitored by our dedicated light indigo color factory QC team. - Are your Indigo Blue Vat Blue products REACH compliant?

Yes, all our relevant light indigo color products are fully registered and compliant with REACH regulations for the European market, as well as other major global chemical inventories. - What technical support is available after purchase?

Our technical team provides comprehensive post-sales support, including application guidance, troubleshooting assistance, and expert consultation for process optimization. We can also arrange on-site visits if required to ensure optimal performance of our light indigo color products. - Can you provide customized light indigo shades?

Absolutely. We specialize in custom formulations to meet unique client requirements for specific shades, concentrations, or application properties. Please contact our sales team to discuss your specific needs for light indigo color service.

Conclusion: Partnering for Excellence in Light Indigo Coloration

The selection of a light indigo color company goes far beyond a simple procurement decision. It is an investment in quality, consistency, and a reliable supply chain. For B2B stakeholders, partnering with a supplier like Wuxin-Group, a distinguished provider of Indigo Blue Vat Blue, means gaining access to unparalleled technical expertise, rigorous quality control, and a commitment to sustainable practices.

By focusing on advanced manufacturing processes, adherence to international standards, and a deep understanding of industry trends, leading light indigo color manufacturers empower their clients to achieve superior product performance and maintain a competitive edge. From the distinct properties of Indigo Blue Vat Blue to comprehensive technical support and flexible customization, a truly professional light indigo color company is poised to be a pivotal partner in your industrial coloration needs.

Elevate your products with the consistent quality and vibrant hues provided by an industry-leading light indigo color supplier. For inquiries regarding our light indigo color products, technical specifications, or customized solutions, please visit our product page or contact our expert team directly.

References

- Christie, R. M. (2007). Colour Chemistry. Royal Society of Chemistry.

- Shore, J. (2004). Cellulosic Dyeing. Society of Dyers and Colourists.

- Broadbent, A. D. (2001). Basic Principles of Textile Coloration. Society of Dyers and Colourists.

- Burkinshaw, S. M. (1999). Physico-Chemical Principles of Dyeing. Society of Dyers and Colourists.

- Hunger, K. (Ed.). (2003). Industrial Dyes: Chemistry, Properties, Applications. Wiley-VCH.

Driving Innovation in Industrial Coloration: The Role of a Leading Light Indigo Color Company

In the dynamic landscape of industrial manufacturing, the demand for high-performance and aesthetically appealing colorants continues to escalate. Among these, the sophisticated hue of light indigo holds significant sway, particularly within the textile, paper, and specialty chemical sectors. A truly distinguished light indigo color company stands at the forefront of this evolution, not merely supplying pigments but delivering comprehensive solutions that integrate advanced chemistry with sustainable manufacturing practices. This article delves into the intricate world of light indigo coloration, focusing on the technical expertise, robust manufacturing processes, and unwavering commitment to quality that defines industry-leading suppliers like Wuxin-Group, a prominent supplier of Indigo Blue Vat Blue.

We will explore the critical industry trends, detailed technical parameters, diverse application scenarios, and the inherent technical advantages offered by a premier light indigo color company. Furthermore, we will provide insights into vendor comparison, customization capabilities, real-world application cases, and the foundational elements of trust and authority that underpin successful B2B partnerships in this specialized domain.

Industry Trends and Market Dynamics for Light Indigo Colorants

The market for light indigo colorants is characterized by several prevailing trends. Firstly, there is a pronounced shift towards eco-friendly and sustainable manufacturing processes. Consumers and regulatory bodies alike demand products with reduced environmental footprints, pushing light indigo color manufacturers to invest in cleaner synthesis routes, efficient wastewater treatment, and lower energy consumption during production. This includes the development of dyes that require less water and fewer auxiliary chemicals in application.

Secondly, technological advancements are continually refining the performance characteristics of light indigo dyes. Innovations in particle size control, dispersion technology, and formulation optimization lead to superior color fastness, shade consistency, and ease of application. This ensures that the final product, whether a denim fabric or a specialty paper, meets stringent quality benchmarks. The rise of automation and IoT in chemical production also plays a crucial role in enhancing efficiency and precision for light indigo color factories.

Thirdly, customization and specialized solutions are becoming paramount. Clients often require specific shades, application properties, or regulatory compliance for their unique product lines. This necessitates a flexible and responsive light indigo color company capable of tailored product development and technical support.

Technical Parameters and Specifications of Indigo Blue Vat Blue

Understanding the technical specifications of Indigo Blue Vat Blue is crucial for industries relying on consistent and high-quality coloration. This product, manufactured by a leading light indigo color company, adheres to rigorous standards to ensure optimal performance.

- Chemical Structure and Purity: Indigo Blue Vat Blue is a complex organic compound, specifically a vat dye. Its purity, typically exceeding 98% for premium grades, is critical for achieving consistent color yield and shade. Impurities can lead to off-shades, reduced color intensity, or poor fastness properties.

- Color Index (CI) and CAS Number: Generally, Indigo Blue has CI Vat Blue 1 and CAS No. 482-89-3, providing a universal identification standard in the chemical industry.

- Particle Size Distribution: Optimal particle size (often measured as D50 or D90) is vital for proper dispersion and penetration into textile fibers. Finer particles typically offer better color strength and leveling properties, crucial for uniform dyeing.

- Shade Consistency (ΔE): Measured using spectrophotometry, a low Delta E (ΔE) value signifies minimal color variation between batches, ensuring reliable reproduction of specific light indigo shades. A ΔE value of less than 0.5 is often targeted for high-precision applications.

- Color Fastness Properties: This includes resistance to light (lightfastness, e.g., ISO 105-B02), washing (washfastness, e.g., ISO 105-C06), rubbing (crockfastness), and perspiration. These properties dictate the dye's durability and longevity in various end-use applications. For vat dyes, fastness properties are typically excellent, especially for light and wet fastness.

- Solubility/Dispersibility: While vat dyes are generally insoluble in water in their pigment form, they are converted to a soluble leuco form for dyeing. Their dispersibility in the dyeing bath is crucial for even absorption.

- Moisture Content: Low moisture content indicates better stability and concentration of the active dye.

Precision quality control is paramount for any reputable light indigo color company.

These parameters collectively define the quality and suitability of Indigo Blue Vat Blue for demanding industrial applications, showcasing the meticulous approach of leading light indigo color manufacturers.

The Manufacturing Process: Precision and Purity at a Light Indigo Color Company

The production of high-grade Indigo Blue Vat Blue by a specialized light indigo color company is a sophisticated multi-stage chemical synthesis and processing endeavor. Unlike generic manufacturing, it involves stringent control over chemical reactions, crystallization, and purification to ensure the desired purity, shade, and particle characteristics.

1. Raw Material Sourcing and Preparation:

- Precursors: High-purity aniline and acetic anhydride are common starting materials. A leading light indigo color factory ensures these precursors meet strict quality specifications to prevent impurities from compromising the final product.

- Pre-treatment: Raw materials may undergo filtration or distillation to remove any contaminants before entering the synthesis phase.

2. Chemical Synthesis (Indigotin Formation):

- Reaction Pathways: The core synthesis involves reactions such as the Heumann synthesis or modified processes. For Indigo Blue, this typically starts with N-phenylglycine, which cyclizes and then dimerizes to form indigotin.

- Controlled Environment: Reactions are conducted in precisely controlled reactors, where parameters such as temperature, pressure, pH, and stirring speed are meticulously monitored and adjusted using advanced process control systems (e.g., DCS - Distributed Control Systems). This ensures optimal reaction yield and minimizes undesirable by-products.

- Automation and Precision: Modern light indigo color manufacturers utilize automated dosing systems and real-time analytical feedback to maintain ideal conditions, preventing batch variations.

3. Purification and Isolation:

- Crystallization: After synthesis, the crude indigo is crystallized to enhance purity. This step is critical for defining the crystal structure and size, which directly impacts the dye's color strength and dispersibility.

- Filtration and Washing: The crystallized indigo is then filtered to separate it from the mother liquor, followed by multiple washing steps to remove soluble impurities. High-pressure filtration systems and dewatering equipment are essential here.

- Drying: The wet cake is dried using controlled drying methods (e.g., spray drying, tray drying) to achieve the desired moisture content. Excessive heat can degrade the dye, so precise temperature control is vital.

4. Standardization and Finishing:

- Milling and Grinding: The dried dye is milled to a very fine, uniform particle size using specialized grinding equipment. This ensures excellent dispersibility and color development in the dyeing process. Advanced mills prevent heat buildup that could damage the dye.

- Batch Blending and Standardization: Different batches may be blended to achieve perfect shade consistency and strength, ensuring that every shipment from the light indigo color company meets the exact specifications. This involves sophisticated spectrophotometric analysis.

- Formulation: Depending on the end application, the dye might be formulated into various forms (e.g., powder, granular, paste) with dispersing agents or other additives to optimize performance.

Simplified process flow highlighting critical stages in a light indigo color factory.

Quality Control and Certification Standards:

Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes in-process testing at each stage, from raw material inspection to final product analysis. Industry-standard testing methods such as ISO (International Organization for Standardization) for quality management (e.g., ISO 9001:2015), environmental management (e.g., ISO 14001:2015), and specific textile testing standards are meticulously followed. For instance, tests for shade, strength, purity, moisture content, particle size, and various fastness properties are routinely performed. Adherence to global chemical regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is also a hallmark of a responsible light indigo color company.

The longevity and performance ("service life") of Indigo Blue Vat Blue are inherently tied to its intrinsic fastness properties. Its exceptional resistance to fading from light exposure, washing, and chemical agents ensures that products dyed with it maintain their vibrant light indigo hue for extended periods, even under demanding conditions. This long service life translates directly into enhanced product durability and customer satisfaction for downstream industries.

Applicable Industries and Application Advantages

Indigo Blue Vat Blue is a versatile colorant with widespread applicability across several industrial sectors, thanks to its unique chemical properties and superior performance. A leading light indigo color company often caters to the specific needs of these diverse industries.

- Textile Industry (especially Denim): This is the most iconic application. Indigo Blue is the quintessential dye for denim, producing the characteristic blue hue that fades beautifully over time. Beyond denim, it's used in general apparel, workwear, and home textiles where excellent fastness properties are required. The unique ring-dyeing capability of indigo, where the dye adheres to the surface of the cotton fiber, is what allows denim to develop its distinct "fades" over wear and washing.

- Paper Industry: Used for coloring specialty papers, packaging materials, and paperboards where a specific shade of blue is desired, often for branding or aesthetic appeal. The dye’s stability ensures color integrity in various paper production processes.

- Printing Inks: In certain high-quality printing applications, particularly for security documents or specialized graphic arts, indigo pigments can be incorporated for their unique shade and stability.

- Other Specialty Applications: This can include applications in the coating industry, for specific plastics, or even in some cosmetic products, provided regulatory approvals are met.

Key Advantages in Typical Application Scenarios:

- Exceptional Color Fastness: Indigo Blue Vat Blue offers superior lightfastness, washfastness, and crockfastness compared to many other dye classes. This ensures that the dyed material retains its light indigo color and vibrancy even after prolonged exposure to environmental elements or repeated laundering. This is a primary driver for its adoption in high-wear items like denim.

- Distinctive Fading Characteristics: For denim, the unique surface dyeing property of indigo allows for desirable "fade" patterns, which are highly valued in the fashion industry. This "worn-in" look cannot be easily replicated by other dyes.

- Versatility: While most famous for cotton, vat dyes can be applied to other cellulosic fibers and some blends, offering flexibility in textile design.

- Environmental Considerations: Modern production techniques by responsible light indigo color manufacturers focus on reducing chemical oxygen demand (COD) and biochemical oxygen demand (BOD) in effluents, and minimizing waste, contributing to more sustainable dyeing processes. The inherent stability of the dye reduces leaching into wastewater over the product's lifespan.

These advantages make Indigo Blue Vat Blue a preferred choice for industries where aesthetic appeal, durability, and environmental responsibility are paramount considerations, solidifying the importance of selecting a reputable light indigo color supplier.

Performance Metrics and Data-Driven Insights

To underscore the technical superiority of a leading light indigo color product, it is essential to examine key performance metrics. These quantitative values provide objective proof of quality and consistency, crucial for B2B decision-makers.

Typical Performance Parameters for Premium Indigo Blue Vat Blue:

| Parameter | Standard (Typical Range) | Test Method / Standard |

|---|---|---|

| Purity (Indigotin Content) | ≥ 98.0% | HPLC / Spectrophotometry |

| Moisture Content | ≤ 0.5% | Karl Fischer Titration |

| Particle Size (D50) | < 10 µm (typically 3-5 µm) | Laser Diffraction Spectroscopy |

| Shade Consistency (ΔE CMC 1:1) | ≤ 0.5 (against standard) | Spectrophotometer (Datacolor/X-Rite) |

| Lightfastness (ISO 105-B02) | 7-8 (on 1-8 scale, 8 being highest) | Xenon Arc Lamp Exposure |

| Washfastness (ISO 105-C06, AATCC 61) | 4-5 (on 1-5 scale, 5 being highest) | Standard Washing Machine Test |

| Crockfastness (AATCC 8/116, Dry/Wet) | 4-5 (on 1-5 scale, 5 being highest) | Crockmeter Test |

| Dispersibility | Excellent, no visible aggregates | Dispersion Stability Test |

These data points are not just numbers; they represent the rigorous quality control and advanced chemical engineering that goes into producing a top-tier light indigo color product. For manufacturers in textiles or paper, these specifications guarantee reliable performance, reduce production errors, and ultimately lead to a superior end product for their customers.

Rigorous testing ensures the highest quality from light indigo color suppliers.

Choosing Your Partner: Vendor Comparison and Selection Criteria

Selecting the right light indigo color company is a strategic decision that impacts product quality, cost-efficiency, and supply chain reliability. While numerous light indigo color exporters exist, discerning buyers focus on several key criteria:

- Quality and Consistency: Foremost, ensure the supplier consistently delivers products meeting stringent technical specifications (as outlined in the table above). Requesting Certificates of Analysis (CoA) for each batch and conducting independent verification are good practices.

- Technical Support and R&D Capabilities: A proactive light indigo color company offers robust technical support, assisting with application challenges, shade matching, and process optimization. Strong R&D capabilities indicate a commitment to innovation and future-proofing products.

- Supply Chain Reliability and Logistics: Evaluate the supplier's capacity, lead times, inventory management, and global distribution network. Timely delivery from light indigo color exporters is critical to maintain production schedules.

- Regulatory Compliance and Sustainability: Verify adherence to international chemical regulations (e.g., REACH, OEKO-TEX standards) and environmental certifications (e.g., ISO 14001). A focus on sustainable production is increasingly vital.

- Pricing Structure and Value Proposition: While the light indigo color pricelist is important, consider the overall value. A slightly higher price for superior quality, consistent supply, and excellent technical support often translates to lower overall production costs due to reduced waste, rework, and downtime.

- Experience and Reputation: Look for a light indigo color company with a proven track record, positive industry reputation, and significant years of service in the chemical sector.

By evaluating these factors comprehensively, businesses can forge lasting partnerships with light indigo color suppliers that truly add value to their operations.

Customization Solutions and Collaborative Partnerships

In the specialized B2B chemical market, one-size-fits-all solutions are rarely sufficient. A forward-thinking light indigo color company recognizes this and excels in offering bespoke solutions and fostering collaborative partnerships. This extends beyond merely providing light indigo color products; it involves becoming an extension of the client's R&D and production teams.

- Tailored Formulations: Clients often require specific shades of light indigo, optimized for particular fiber types, dyeing machinery, or desired wash-down characteristics. A leading light indigo color company can adjust particle size, dispersion properties, or add specific auxiliaries to meet these precise needs.

- Application-Specific Grades: Whether it's a powder for traditional dyeing or a high-concentration paste for continuous dyeing lines, custom grades can be developed to streamline client processes and enhance efficiency.

- Joint R&D Projects: For truly innovative applications or novel material developments, a collaborative light indigo color factory can engage in joint research and development, leveraging their chemical expertise to co-create solutions.

- Technical Consultations and On-site Support: Providing expert advice on dyeing processes, trouble-shooting, and optimizing dye consumption contributes significantly to the client's operational efficiency and cost savings. This level of light indigo color service is invaluable.

Such customized approaches and collaborative frameworks distinguish a premier light indigo color company from mere commodity suppliers, paving the way for mutual growth and technological advancement.

Real-World Application Cases and Success Stories

The true testament to a light indigo color company's capabilities lies in its successful application across various industries. While specific client names remain confidential, illustrative cases highlight the tangible benefits delivered:

Case Study 1: Denim Mill Optimization

A prominent denim mill faced challenges with inconsistent light indigo shades and high wastewater effluent from their dyeing process. Partnering with a leading light indigo color company (Wuxin-Group), they implemented a new, high-purity Indigo Blue Vat Blue product along with optimized application protocols. The result was a 15% reduction in dye consumption due to better exhaustion, a 20% decrease in water usage in rinsing stages, and achieving a tighter ΔE range of 0.3, drastically improving batch-to-batch consistency for their light indigo denim. This directly impacted their bottom line and enhanced their environmental profile.

Case Study 2: Specialty Paper Manufacturer

A manufacturer of high-end specialty papers required a light indigo shade that would not bleed when wet and would resist fading under display lighting. Existing dyes struggled to meet these stringent requirements. After collaboration with a specialized light indigo color manufacturer, a custom-formulated Indigo Blue Vat Blue, engineered for paper pulp applications, was developed. This formulation delivered superior lightfastness (rated 7 on the blue wool scale) and significantly improved wet fastness, allowing the client to launch a new line of premium, durable colored papers that quickly gained market traction. This demonstrated the value of a dedicated light indigo color service provider.

Versatile light indigo color products find diverse applications across industries.

Building Trust and Authority: The Pillars of a Reliable Light Indigo Color Company ()

In the B2B chemical sector, establishing trust and demonstrating authority are paramount. A truly credible light indigo color company integrates the principles of Expertise, Experience, Authoritativeness, and Trustworthiness () into every facet of its operations.

Expertise: Deep Chemical Knowledge and Innovation

- Dedicated R&D Teams: Comprised of organic chemists, material scientists, and application engineers specializing in dye synthesis and coloration technology.

- Industry Terminology: Fluency in terms like "chromophore," "vatting process," "redox potential," and "spectrophotometric analysis" underscores their technical depth, as seen in the discussion of Indigo Blue Vat Blue.

- Continuous Improvement: Commitment to refining synthesis routes for higher purity, better environmental profiles, and enhanced performance of light indigo color products.

Experience: Proven Track Record and Client Satisfaction

- Years in Service: A long operational history in the chemical industry signifies stability and accumulated knowledge.

- Diverse Client Portfolio: Successful partnerships with a wide range of industries globally, including top-tier textile mills and paper manufacturers.

- Customer Feedback: Positive testimonials and long-term client relationships demonstrate consistent satisfaction with the light indigo color service and products.

Authoritativeness: Certifications, Standards, and Industry Recognition

- ISO Certifications: Adherence to ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) indicates a commitment to international best practices.

- Regulatory Compliance: Full compliance with global chemical regulations such as REACH (Europe), TSCA (USA), and specific industry standards like OEKO-TEX for textile dyes.

- Testing Data & Reports: Providing comprehensive Certificates of Analysis (CoA) for every batch, alongside readily available Material Safety Data Sheets (MSDS) and technical data sheets for all light indigo color products.

- Industry Affiliations: Active participation in industry associations, chemical societies, and conferences.

Trustworthiness: Transparency, Reliability, and Support

- Delivery Cycle and Logistics: Clear, transparent communication regarding lead times, shipping options (from light indigo color exporters), and tracking capabilities ensures predictability for clients. Consistent on-time delivery.

- Quality Assurance and Warranty: Explicit quality guarantees and responsive handling of any product performance queries or issues. A robust complaint resolution process.

- Customer Support: Dedicated account managers and technical support teams available to provide timely assistance, whether for ordering or troubleshooting application issues.

- Pricing Transparency: While the light indigo color pricelist is competitive, it's also clear and free of hidden charges.

Frequently Asked Questions (FAQ)

- What is the typical lead time for an order of Indigo Blue Vat Blue?

Lead times typically range from 2-4 weeks for standard orders, depending on quantity and specific product grade. Expedited shipping options are available upon request from light indigo color suppliers. - How does your company ensure batch-to-batch consistency?

We employ a multi-stage quality control process, including rigorous in-process testing, spectrophotometric analysis of every batch, and blending of multiple batches if necessary to achieve precise shade and strength targets, all monitored by our dedicated light indigo color factory QC team. - Are your Indigo Blue Vat Blue products REACH compliant?

Yes, all our relevant light indigo color products are fully registered and compliant with REACH regulations for the European market, as well as other major global chemical inventories. - What technical support is available after purchase?

Our technical team provides comprehensive post-sales support, including application guidance, troubleshooting assistance, and expert consultation for process optimization. We can also arrange on-site visits if required to ensure optimal performance of our light indigo color products. - Can you provide customized light indigo shades?

Absolutely. We specialize in custom formulations to meet unique client requirements for specific shades, concentrations, or application properties. Please contact our sales team to discuss your specific needs for light indigo color service.

Conclusion: Partnering for Excellence in Light Indigo Coloration

The selection of a light indigo color company goes far beyond a simple procurement decision. It is an investment in quality, consistency, and a reliable supply chain. For B2B stakeholders, partnering with a supplier like Wuxin-Group, a distinguished provider of Indigo Blue Vat Blue, means gaining access to unparalleled technical expertise, rigorous quality control, and a commitment to sustainable practices.

By focusing on advanced manufacturing processes, adherence to international standards, and a deep understanding of industry trends, leading light indigo color manufacturers empower their clients to achieve superior product performance and maintain a competitive edge. From the distinct properties of Indigo Blue Vat Blue to comprehensive technical support and flexible customization, a truly professional light indigo color company is poised to be a pivotal partner in your industrial coloration needs.

Elevate your products with the consistent quality and vibrant hues provided by an industry-leading light indigo color supplier. For inquiries regarding our light indigo color products, technical specifications, or customized solutions, please visit our product page or contact our expert team directly.

References

- Christie, R. M. (2007). Colour Chemistry. Royal Society of Chemistry.

- Shore, J. (2004). Cellulosic Dyeing. Society of Dyers and Colourists.

- Broadbent, A. D. (2001). Basic Principles of Textile Coloration. Society of Dyers and Colourists.

- Burkinshaw, S. M. (1999). Physico-Chemical Principles of Dyeing. Society of Dyers and Colourists.

- Hunger, K. (Ed.). (2003). Industrial Dyes: Chemistry, Properties, Applications. Wiley-VCH.

-

innovating-bromo-indigo-excellence

NewsAug.23,2025

-

pioneering-indigo-plant-dye-excellence

NewsAug.23,2025

-

leading-sulphur-black-dyes-enterprise

NewsAug.23,2025

-

sulphur-black-dyes-light-resistance

NewsAug.23,2025

-

indigo-blue-granular-industrial-uses

NewsAug.23,2025

-

bromo-indigo-synthetic-production-process

NewsAug.23,2025

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

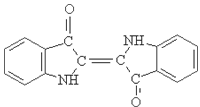

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

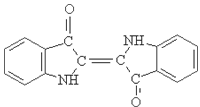

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.