Jeans Garment Dyeing with Sulfur Dyes

Why Garment Dyeing?

Garment dyeing is a method of dyeing fully-fashioned garments such as t-shirts, sweaters, dresses, stockings and jeans. In the conventional method of fabric manufacturing, fabric that has been pre-dyed (piece-dyed) is cut-and-sewn into garments.

The conventional method has the advantage in terms of cost effectiveness of mass production of fabric in specific colors. The most significant disadvantage in the conventional approach is the economic risk of carrying a large inventory of limited styles or colors in a fashion market that is constantly changing.

Dye Selection in Cotton Garment Dyeing

The primary options for dyeing black in cotton garments are direct dyes, reactive dyes , pigments and sulfur dyes.

Direct dyes

- These require very high dyeing temperatures, and large amounts of electrolyte such as salt for dyeing . Additionally, direct dyes, especially in dark shades, require a fixing agent to be applied at the end of the dyeing cycle for reasonable wash- and crock fastness. Directs offer the lowest dye costs per garment and are simple to apply.

Reactive dyes

- These dyes were chemically-engineered in the mid-20th century to provide a technique for dyeing cotton that was simple enough so that an understanding of dye chemistry was not necessary. Designed to be nearly “idiot-proof” in application, this class of dyes is highly favored in operations where costs and productivity are not considered important.

Pigments

- Pigments are primarily of interest in producing so-called “distressed look”. Pigments, unlike dyes, are insoluble which means that they do not penetrate into fibers or yarns and sit on the surface of the garments which allows an immediate “worn” appearance more economically than dyeing followed by abrasion. The cycle time is low and the energy and water requirements are lower than dyeing. They can present a problem with machine contamination, the shades are generally dull and the crockfastness and wash-fastness are low.

Sulfur dyes

- Sulphur dyes are still heavily favored by leading jeans producers, especially when the blue-black tone of reactive blacks can be reproduced.

The primary advantages of using sulfur dyes as opposed to reactives in dyeing jeans are:

- Sulfur dyes produce dark shades at much lower costs than reactive dyes.

- The dyeing cycle time and water consumption can be 50% less than with reactive dyes.

- Energy costs, especially with steam and hot water are greater with reactive dyes.

- Reactive dyes are high-chroma dyes, like acid dyes, producing intense, bright shades that convey an unnatural appearance. Because sulfur dyes form clusters of molecules like Indigo, the low-chroma appearance reproduces so-called “earth-tones” favored in jeans.

- Repeatability of shade, coverage of immature cotton and the ability to produce novelty effects are additional advantages with sulfur dyes.

Sulfur dyes, like Indigo are insoluble in water and after washing are much easier to remove from waste streams than reactives or directs. Sulfur dyes can also be recovered and reused or are suitable for application in standing baths.

Forms of Sulfur Dyes

Sulfur dyes are available in powder or liquid forms. Sulfur powders have a lower direct cost, but the quality can be variable and analytical tests should be conducted to determine purity, strength and dyeing consistency. Powders can be difficult to solubilize resulting in poor color-fastness to crocking and washing and are difficult to prepare for dyeing. With adequate reduction of the dye, powders can produce adequate results in batch dyeing where circulation is strong as in package or garment dyeing, but should be avoided in continuous dyeing,especially on Indigo dyeing machines. Liquids sulfur dyes can be added to machines with littleor no preparation and yield higher quality dyeings.

Liquid sulfur dyes which are pre-reduced, generally are available in 2 forms:

- The low-sulfide pre-reduced dyes, identified commercially as RDT’s, which normally use a reducing sugar(dexrins, corn syrup, sugar, molasses) for reduction. This type of pre-reduced sulfur compared to the sulfide-type reduced dye has the following characteristics: low odor, shorter dyeing cycle, higher salt requirement in batch dyeing, strike (how fast the dye goes on the fabric-too fast a strike results in uneven shade) is controlled by rate of temperature increase, higher costs than the sulfide type, a lower chemical oxygen demand in water treatment and less water use.

- The sulfide/polysulfide pre-reduced dyes have a sulfur odor, a longer dye cycle in some applications, requires less salt, the strike rate is controlled by how quickly the dye is added and this type can be used at much lower cost. Sodium sulfide should not be utilized as the reducing agent because of low solubility. The more soluble sodium hydrosulfide (NaSH) offers much greater dyeing quality and low costs. There are other hydrosulfide reducers than can dye sulfurs at a pH as low as 9.5 and are suitable for dyeing wool and silk with sulfurs alone or in blends with cotton.

Temperature considerations are significant. The low-sulfide dyes or any sulfur dye that is reduced with the RDT principle requires a higher dyeing temperature, usually 90 C for all sulfur colors while the soluble sulfides (NaSH) can be applied at temperatures from 30 to 70 C. In addition to much higher energy consumption during dyeing, as temperature increases the strike rate increases which means that the dye will go onto the garments so quickly, that shade variation can occur and other than dark shades such as sulfur blacks, the use of the reducing sugar (RDT) type of reduction should be avoided for light and medium shades with sulfurs and especially not with blends of 2 or more sulfur dyes. Additionally, there is great flexibility with

“Tones” in Sulfur Dyes

The word “tone” refers to an effect that causes different color appearances in which the black possesses a reddish, bluish or greenish effect. In terms of strict color science, “black is not a color, but a “condition of equal reflectance across visible wavelengths of light at low levels”. Black, like neutral greys and white do not possess hues such as red, green, yellow, blue etc. The reddish tone in sulfur blacks is common, but not as desirable as a blue-black commonly produced in garment dyeing with reactive black. Producing a blue-black with powder dyes is difficult and for the bluish tone, there are specific liquid dyes that are available for this purpose. Most liquid sulfur blacks will produce a greenish tone at adequate levels of reduction. In addition to the various tones that are produced with different sulfur dye products, there also exists a contrast between “brighter” and “duller” appearances which in color science correspond to “high chromatic” and “low chromatic. The better the dye dispersion the higher the chroma or brightness. High chroma dyeings are more colorfast, but have a lighter appearance.

-

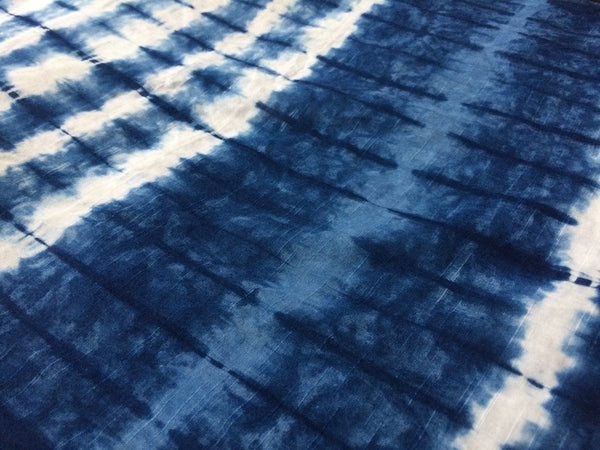

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.